20

April 2005

®

DUCT COLLAR INSTALLATION INSTRUCTIONS

FOR GH, GW, GK, GX, & GG SERIES HOODS

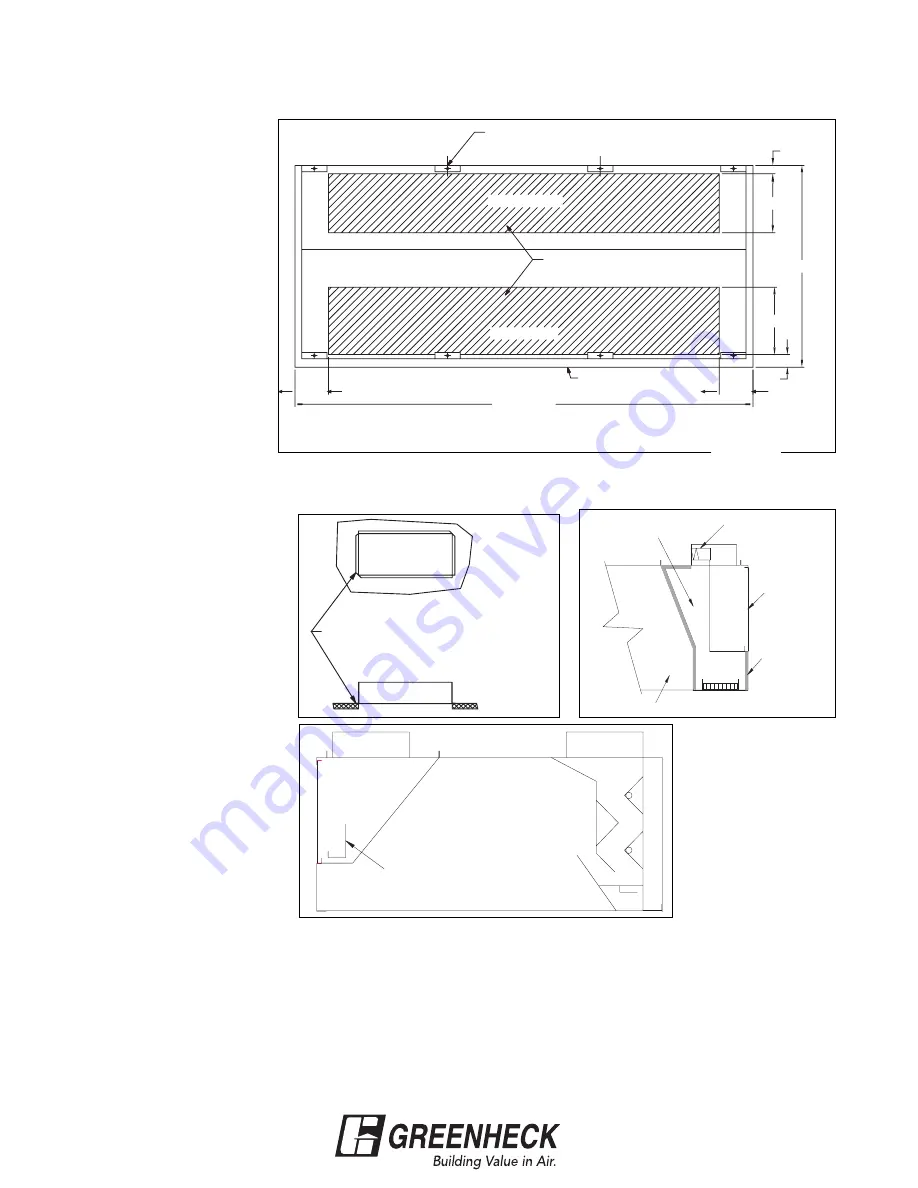

8.00

Hood Length

Front of Hood

Supply Plenum

Duct Cut Out Area

Exhaust Plenum

Hangar Bracket

3.00

10.00

Hood Width

16.00

3.00

8.00

1.

The exhaust duct

connection needs to be

located within 48 in. from

the center of the hood

length to the center of

the duct connection.

(see Fig. 20A)

2.

The exhaust duct

connection is to be a

continuous liquid tight

weld.

Weld with a non-

ferrous filler wire, such

as silicon bronze or

stainless steel filler

wire. Protect all

stainless steel areas

from weld splatter.

3.

The supply duct

connection is tack

welded at 1 in. to 2 in.

intervals, or sheet metal

screws at 3 in. to 6 in.

spacing to the hood.

(see Fig. 20B)

4.

The deflector is centered

under the supply duct

collar. (see Fig. 20C)

5.

For hoods that are

insulated, the edges of

the insulation need to be

taped after the hole is

cut, (the insulation tape

is to be provided by

others).

6.

On combination hoods,

make sure the fire

damper is located over

the internal supply

chamber. (see Fig. 20D)

Return to page 9.

Fig. 20A

Top View of the Hood

1" TO 2" TACKS OR SHEET METAL SCREWS AT 3" TO

6" SPACING TO HOOD.

SUPPLY DUCT CONNECTION TO BE TACK WELDED WITH

CONNECTION

SUPPLY DUCT

Fig. 20B

Fig. 20D

Fig. 20C

SUPPLY

FIRE DAMPER

INTERNAL

SUPPLY

CHAMBER

HOOD

INSULATED

SUPPLY PLENUM

EXHAUST

CAPTURE

DEFLECTOR TO BE PLACED CENTERED

UNDER THE SUPPLY DUCT COLLAR

Note: UL listed hood

assembly to be used

only with Greenheck

Fan Corp. labeled

subassembly for

exhaust hood without

exhaust damper part

Number DC.

Summary of Contents for 458292

Page 54: ...54 April 2005 Date Notes ...

Page 55: ...55 April 2005 Date Notes ...