6

Model BDF • Belt Drive Duct Fan

®

Troubleshooting

WARNING: Before taking any corrective action, make certain unit is not capable of operation during

repairs.

PROBLEM

CAUSE

CORRECTIVE ACTION

Excessive noise

or vibration

Wheel unbalance

Clean all dirt off wheel. Check wheel balance, rebalance in place if

necessary.

Bad bearings

Replace.

Belts too tight or too loose

Adjust tension, see figure 7.

Wheel improperly aligned and

rubbing

Center wheel on inlet.

Loose drive or motor pulleys

Align and tighten. See “Pre-Starting Checks”, see page 4-5.

Foreign objects in wheel or housing Remove objects, check for damage or unbalance.

Reduced airflow

System resistance too high

Check system: Proper operation of backdraft or control dampers,

obstruction in ductwork, clean dirty filters.

Unit running backwards

Correct as shown in figure 4.

Excessive dirt buildup on wheels

Clean wheel.

Improper wheel alignment

Center wheel on inlets. See “Pre-Starting Checks”, see page 4-5.

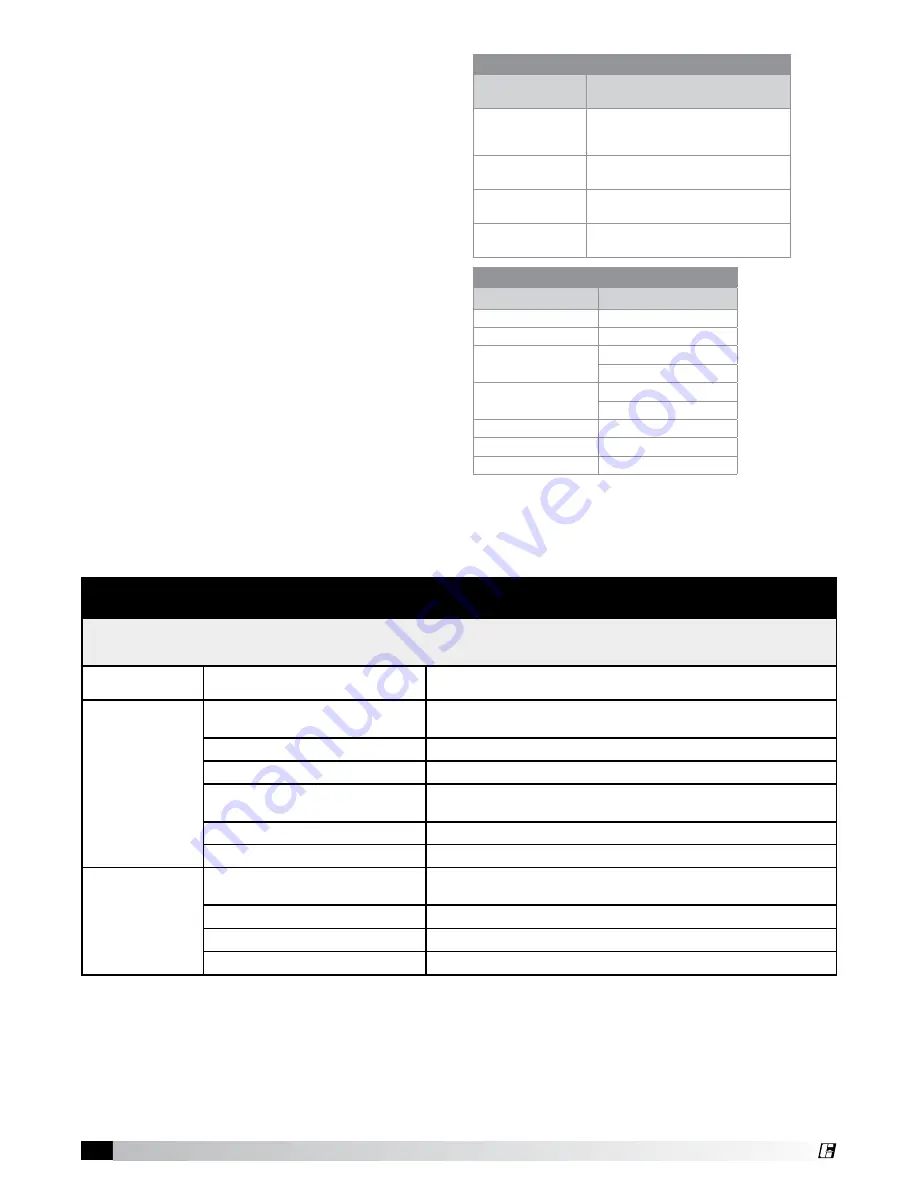

Table 1: Suggested Fan Bearing Greasing Intervals

Interval (months)

Type of Service

1 to 3

Heavy duty in dirty, dusty locations;

high ambient temperatures; moisture

laden atmosphere; vibration.

3 to 6

12 to 24 hours per day, heavy duty,

or if moisture is present

6 to 12

8 to 16 hours per day in clean,

relatively dry atmosphere

12 to 18

Infrequent operation or light duty in

clean atmosphere

Table 2: Grease Manufacturers

Manufacturer

Grease (NLGI #2)

U.S. Electric Motors

Grease No. 83343

Chevron U.S.A. Inc

Chevron SRI Grease #2

Mobil Oil Corporation

Mobilith

Mobil 532

Texaco, Inc.

Premium BRB #2

Texaco Multifak #2

Amoco Oil Co.

Rykon Premium #2

Exxon

Unirex N2

Shell

B Shell Alvania #2

4. Once installed, adjust belts as shown in

“Pre-Starting Checks.”

5. Shaft bearings can be classified in two

groups: relubricating and non-relubricating.

B

earings on sizes 80 through 180 are factory

lubricated and require no further lubrication

under normal use (between -20°F and 180°

F

in a relatively clean environment). Bearings on

size 200 are relubricatable. These bearings

will require frequent lubrication. Caution

should be employed to prevent overpacking or

contamination.

6. Grease fittings should be wiped clean. The unit

should be in operation while lubricating. Extreme

care should be used around moving parts.

7. Grease should be pumped in very slowly until a

slight bead forms around the seal. A high grade

lithium base grease should be used.

Recommended Relubrication

Frequency in Months

NOTE: If unusual environment conditions exist

(extreme temperature, moisture or contaminants)

more frequent lubrication is required.

A good quality lithium base grease, conforming to

NLGI Grade 2 consistency, such as those listed here

may be used.