5

Ceiling Exhaust and Inline Fans

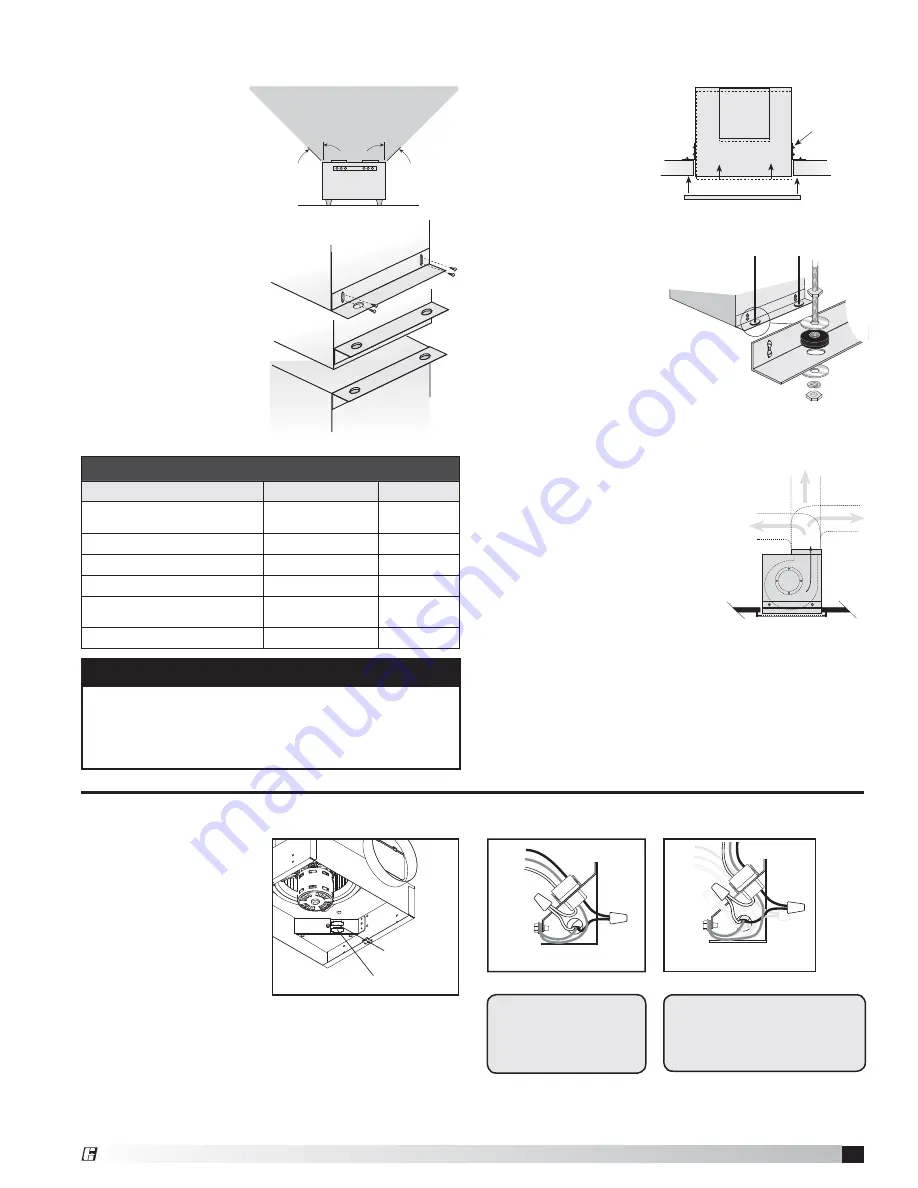

Wire the Fan

115 & 277 Volt

Black wire is “Hot”

White wire is “Neutral”

Green wire is “Ground”

220 - 240 Volt

Black wire is “Hot”

White wire is “Hot”

Green wire is “Neutral/Ground”

Fig. 7a

Fig. 7b

1. Remove wiring cover.

If fan/light combination

is being used, make

sure the fan plug is

connected to the fan

receptacle and the light

plug is connected to

the light receptacle,

shown in Fig. 6.

Using proper wire

connectors, wire the fan as shown in Fig. 7a.

For wiring of light proceed to Fig. 7b.

2. Push all wiring into the unit’s cover and replace

wiring cover.

For Frame Construction:

Position unit between

joists. Position brackets

such that bottom

edge of housing will

be flush with finished

ceiling, and tighten the

adjustable mounting

brackets, shown in

Fig. 3.

For Hanging

Installations:

Use Greenheck’s

optional vibration

isolator kit Part Number

VI Kit. Using the fan’s

standard adjustable

mounting brackets and

10 by 32 threaded rod

(by others), hang unit as

shown in Fig. 4.

Install the Fan

1. For best

performance,

choose a location

with the shortest

possible duct run

and minimum

number of elbows.

Do not mount near

cooking equipment, as

shown in Fig. 1.

2. Attach adjustable

mounting brackets

to fan, but leave the

screws loose until

proper height is

determined, shown

in Fig. 2. Cut hole to

dimensions shown

in table below:

3. Installation of ductwork

is critical to the performance

of the fan, shown in Fig. 5.

Straight ductwork (1) or

ductwork that turns in

the same direction as the

wheel (2) is recommended.

Ductwork turning opposite

the wheel direction (3) will

cause turbulence and back

pressure resulting in poor

performance.

4. Slide ductwork over the fan’s discharge collar and

securely attach it with sheet metal screws.

Make sure the screws do not interfere with damper

operation. Check damper to make sure it opens freely.

Top Mount

Bottom Mount

Brackets can be

used in either

position to adapt to

most mounting

situations

Bottom Mount

Fig. 2

Slots in the

brackets

allow fine

adjustment

for flush

fit with

wall/ceiling

opening

AIRFLOW

1

(GOOD)

3

(POOR)

2

(GOOD)

Fig. 5

45°

45°

Do not install

fan in this area

Ceiling Openings

Sizes

Fan or Fan/Light

Fan/CRD

SP-A50, A70, A90

SP-A110, A125, A190

10

7

⁄

8

x 13

3

⁄

8

11

1

⁄

8

x 13

7

⁄

16

SP-A200, A250, A290, A390

12

1

⁄

8

x 14

1

⁄

4

12

1

⁄

4

x 14

3

⁄

8

SP-A700

23

3

⁄

4

x 11

3

⁄

4

24

1

⁄

8

x 12

1

⁄

4

SP-A410, A510, A710, A780

14

3

⁄

4

x 18

3

⁄

8

14

7

⁄

8

x 18

7

⁄

16

SP-A900, A1050, A1410,

A1550

14

3

⁄

4

x 24

14

7

⁄

8

x 24

1

⁄

8

SP-B 50 - 200

14

1

⁄

8

x 11

3

⁄

4

14

3

⁄

8

x 12

1

⁄

4

Fig. 3

Fig. 4

NOTE

Model SP-A 50-90 are standard with a round duct.

Should Model SP-A 110-190 require a round duct,

Model RDC (Round Duct Connector) may be ordered

from Greenheck for field installation

.

Fig. 1

Fig. 6

Light

Fan

Fan Outlet (top)

Light Outlet (bottom)

®