12

474118

• Model VKERS-MD IOM, Rev. 1, April 2011

Copyright 2011 © Greenheck Fan Corp.

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from

the shipment date. Any units or parts which prove defective during the warranty period will be replaced at our option

when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a period of

one year. Should motors furnished by Greenheck prove defective during this period, they should be returned to the

nearest authorized motor service station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

Greenheck Catalog Vektor ERS-MD provides additional

information describing the equipment, fan performance,

available accessories, and specification data.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com •

Website: www.greenheck.com

Warranty

AMCA Publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans, provides

additional safety information. This publication can be

obtained from AMCA International, Inc. at: www.amca.org.

8 ROW COIL

193.8"

EXTERNAL

PIPING BY OTHERS

SERVICE DOOR

155"

INTAKE OPENING

NEMA 3R DISCONNECT

INSPECTION PANEL

1" DRAIN

(PER FAN)

VK-MD-33 (QTY. 2)

ROOF CURB

1.5" DRAIN

BOTH SIDES

.75" DRAIN

LIFT LUG

(QTY. 8)

S

S

S

S

S

S

38"

126.5"

ISOLATION DAMPER

SIDE INLET

Coil

Coil

Optional

External

Piping

(by others)

Service Doors

Internal Pipe

Chase

Side or Bottom Intake Opening

Lift

Bracket

Optional

Internal

Piping

(by others)

under

Vektor fans

Bypass

Weatherhood(s)

Vektor bypass

air plenum

optional mounting

locations shown

Filters

Coil

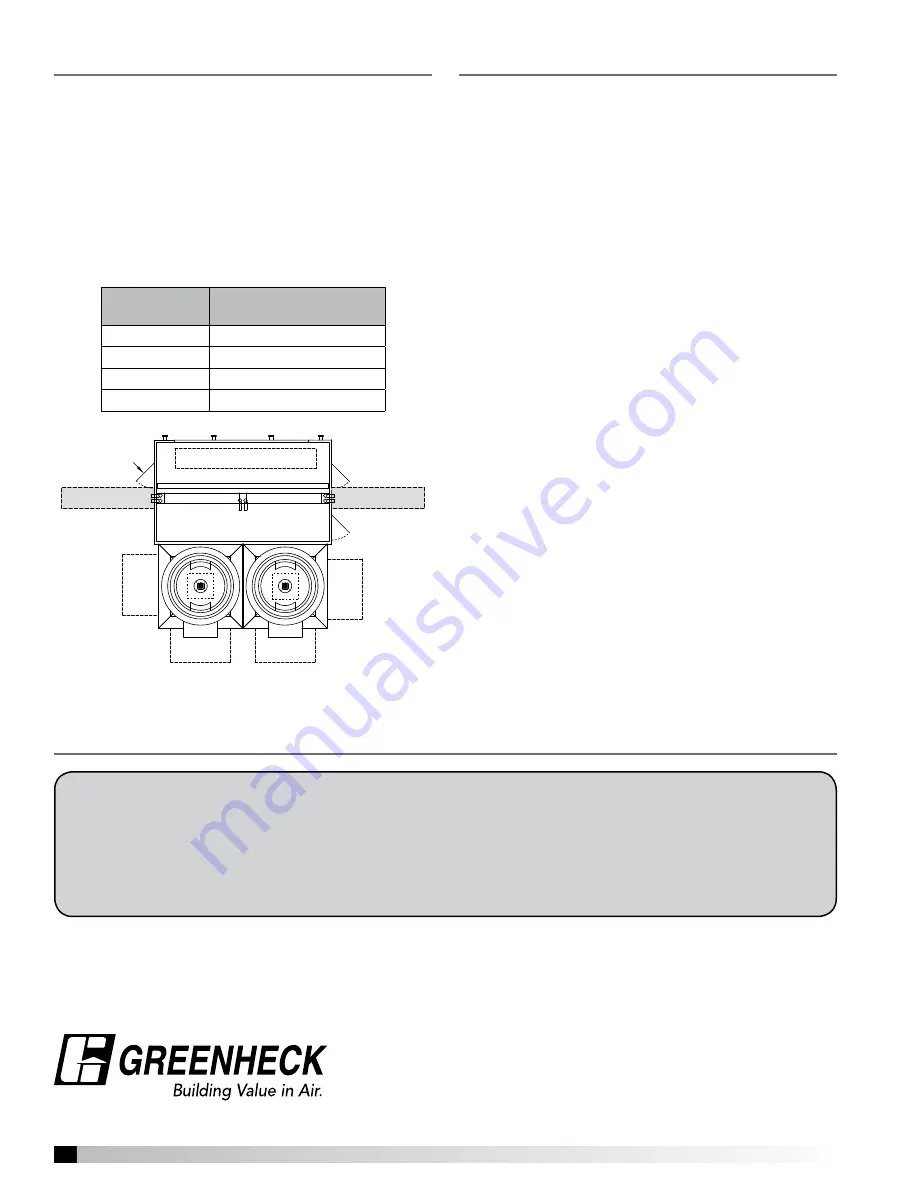

Single and Dual Coil Removal Clearances

Coil

Coil

Service Doors

Coil Service

Clearance

Coil Service

Clearance

WEIGHTS (LBS)

CURB

600

FAN (QTY. 2)

4580

FAN BAP

2750

ERS PLENUM

3700

TOTAL

11630

Clearance

Clearance

Used on page 5 of Part #474118 - need to copy, and edit this same drawing for use on backcover of same Instruction.

Used on backcover of Part #474118

Service

Coil Change Out Procedure

Coils can only be pulled out through the side of the

plenum cabinet. Side panels which are nearest to the

coil can be removed if the coil needs to be replaced.

Size 020 ERS plenums only have a single coil and do

not require coil removal clearances on both sides. If

necessary, both coils can be removed through the

same side of the plenum housing. This process would

require the removal of an additional spacer panel that

separates the two coils within the unit.

Cabinet

Size

Minimum Clearance

(inches)

020

114

030

74 (each side)

040

100 (each side)

060

132 (each side)

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Maintenance Log