4

Vektor ERS-MD Energy Recovery Plenum Laboratory Exhaust

CAUTION

When installing an ERS plenum cabinet, ensure

the proper protective devices are used to protect

personnel from moving parts and other hazards.

Check local codes to ensure compliance for all

protective devices.

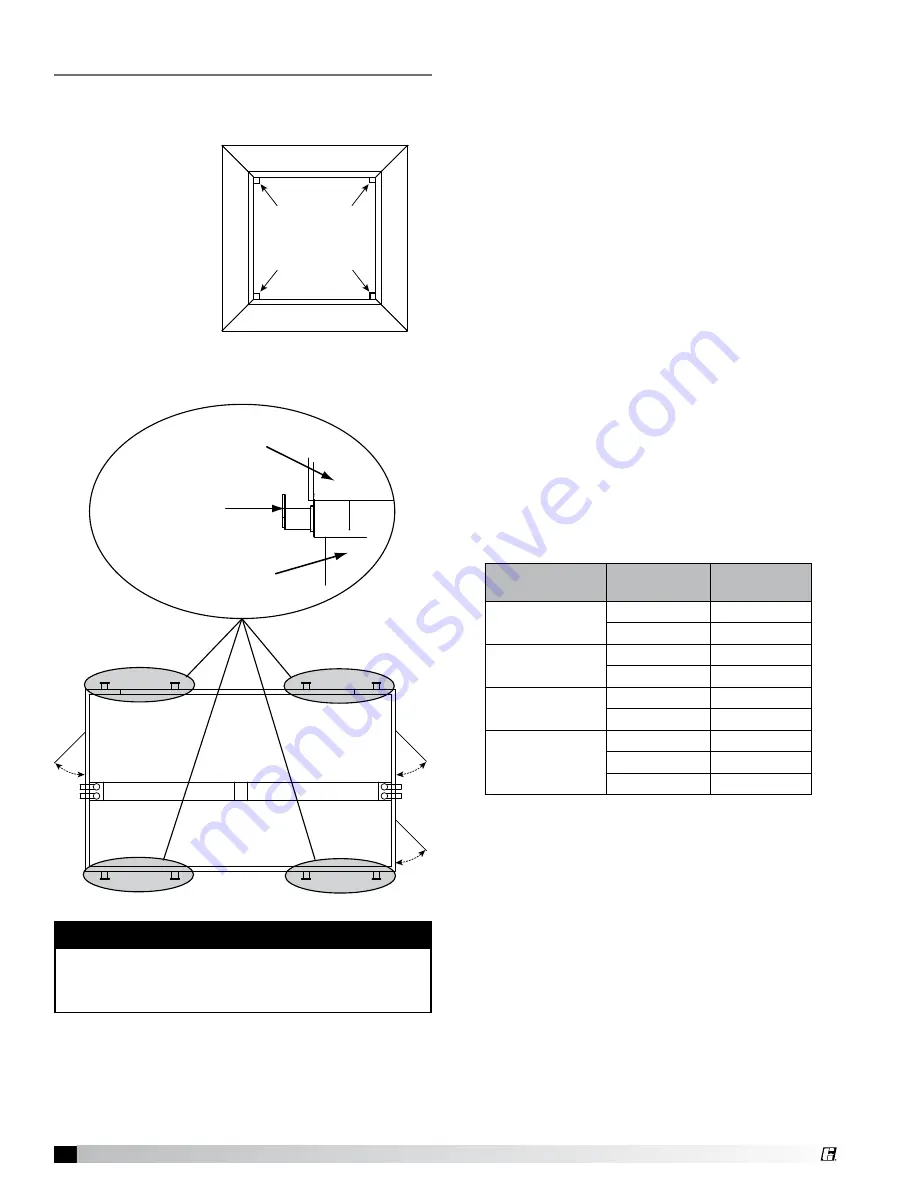

ERS plenum cabinet with coil section should be lifted/

hoisted by lifting brackets provided. These brackets

are located around the lower perimeter of the plenum

cabinet.

1. Before lifting, be sure that all shipping material

has been removed from unit.

2. To assist in determining rigging requirements,

weights are shown below.

3. Unit must be lifted by the lifting brackets

provided on base structure.

4. Rigger to use suitable mating hardware to attach

to unit lifting brackets.

5. Two spreader bars must span the unit to prevent

damage to the cabinet by the lift cables.

6. Always test-lift the unit to check for proper

balance and rigging before hoisting to desired

location.

7. Never lift units in windy conditions.

8. Preparation of curb and roof openings should be

completed prior to lifting unit to the roof. Verify

the curb has the gasket seal on the top surface.

9. Do not use fork lifts for handling unit.

Cabinet

Size

Cabinet

Height

Weight

(lbs)*

020

075

3700

090

4500

030

075

4300

090

4900

040

075

5400

090

6100

060

075

6900

090

7800

110

8300

* Weights shown are for largest coil and filter

options per cabinet size. Based on dry

weight. Weights for custom designed units

may vary.

Unit Weights (ERS Plenum Section Only)

Installation

ERS plenum cabinets and fan bypass air plenums

are to be rigged and moved by the lifting brackets

provided. Handle

in such a manner

as to keep from

scratching or

chipping the

coating. Damaged

finish may reduce

ability of cabinet

to resist corrosion.

See coating repair

section of this

manual for details

involving touch-

up of damaged

surfaces.

Service

Door

Service

Door

Service

Door

TOP VIEW

of

PLENUM SECTION

Lifting Bracket

(removable after

installation)

ERS Plenum Housing

Roof Curb

Fan Bypass

Air Plenum

Lift Points

Top view of

Bypass Air Plenum