FumeJet

®

Fume Exhaust Fans

10

®

Belt Drive Maintenance

V-belt drives must be checked on a regular basis

for wear, tension, alignment and dirt accumulation.

Premature or frequent belt failures can be caused by

improper belt tension (either too loose or too tight)

or misaligned sheaves. Abnormally high belt tension

or drive misalignment will cause excessive bearing

loads and may result in failure of the fan and/or motor

bearings. Conversely, loose belts will cause squealing

on start-up, excessive belt flutter, slippage and

overheated sheaves. Either excessively loose or tight

belts may cause fan vibration.

When replacing V-belts on multiple groove drives all

belts should be changed to provide uniform drive

loading. Use a set of matched belts whenever possible.

Do not pry belts on or off the sheave. Loosen belt

tension until belts can be removed by simply lifting the

belts off the sheaves. After replacing belts, ensure that

slack in each belt is on the same side of the drive. Belt

dressing should never be used.

Do not install new belts on worn sheaves. If the sheaves

have grooves worn in them, they must be replaced

before new belts are installed.

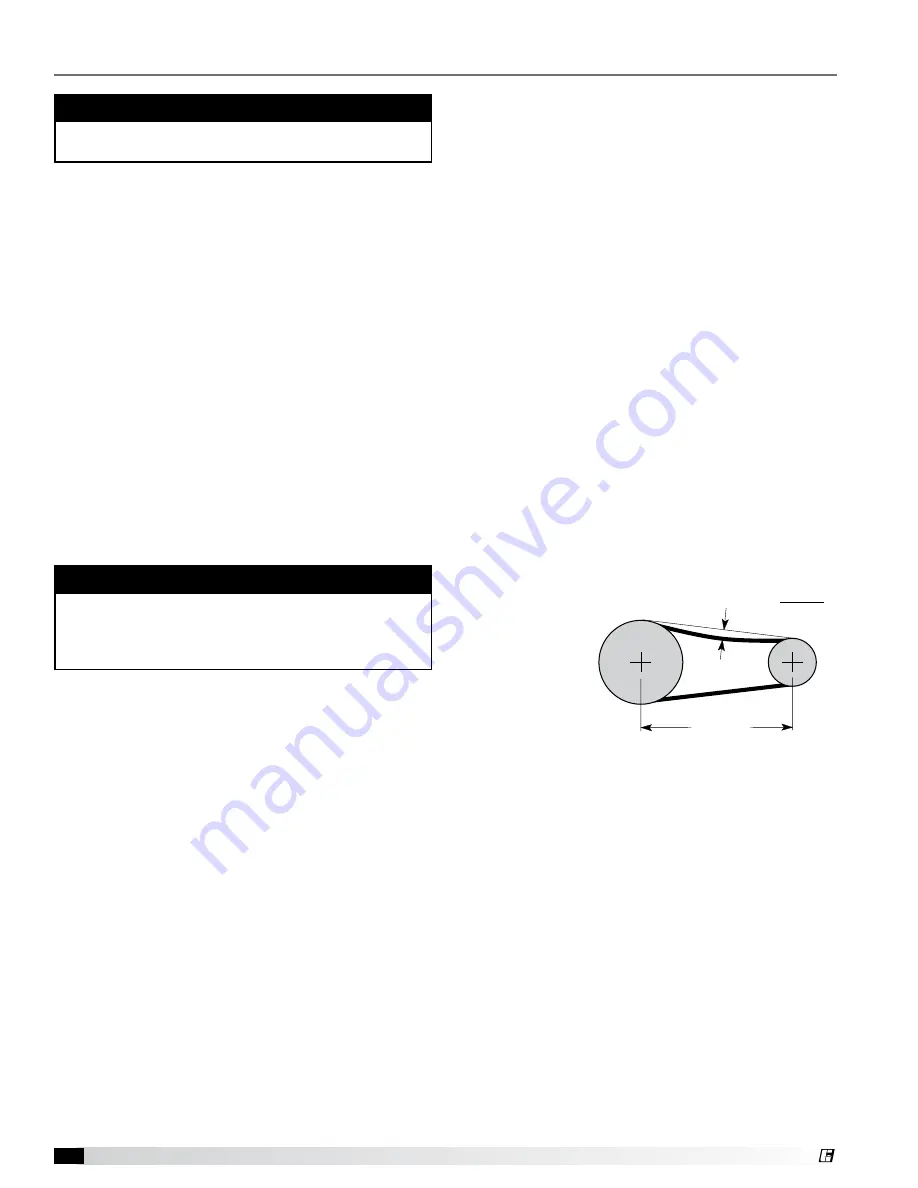

The proper tension for operating a V-belt drive is

the lowest tension at which the belts will not slip at

peak load conditions. Belts are adjusted by raising or

lowering the motor

pivot plate. For

initial tensioning,

the proper

belt deflection

halfway between

sheave centers is

1/64-inch for each

inch of belt span.

Check belt tension two times during the first

24 hours of operation and periodically thereafter.

Belt Span

Deflection = Belt Span

64

Once the unit has been put into operation, a routine

maintenance schedule should be set up to accomplish

the following:

1. Lubrication of bearings and motor.

2. Wheel, housing, bolts and set screws on the entire

fan should be checked for tightness.

3. Any dirt accumulation on the wheel or in the housing

should be removed to prevent unbalance and

possible damage.

4. Inspect fan impeller and housing looking for fatigue,

corrosion, or wear.

Fan Operation

All fans should be run every thirty (30) days, or at least

“bumped” every thirty days. It is preferred that each

fan is run as this causes all electrical and mechanical

components to get up to temperature, displacing any

formed condensation, redistributes load on bearings,

and redistributes grease in the bearings (motor and

shaft bearings).

IMPORTANT

When operating conditions of the fan are to be

changed (speed, pressure, temperature, etc.), consult

manufacturer to determine if the unit can operate

safely at the new condition.

Motors

Motor maintenance is generally limited to cleaning

and lubrication. Cleaning should be limited to exterior

surfaces only. Removing dust and grease buildup on

the motor housing assists proper motor cooling. Never

wash-down motor with high pressure spray.

Greasing of motors is only intended when fittings are

provided. Many fractional motors are permanently

lubricated for life and require no further lubrication.

Motors supplied with grease fittings should be

greased in accordance with the manufacturer’s

recommendations. When motor temperature does not

exceed 104ºF

(40ºC)

, the grease should be replaced

after 2000 hours of running time.

Routine Maintenance and Operation

WARNING

Before taking any corrective action, make certain unit

is not capable of operation during repairs.