35

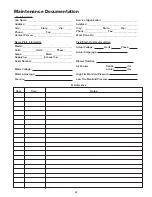

Maintenance Instructions:

Furnace

Combustion Blower Motor

Motor maintenance is generally limited to cleaning. Cleaning should be limited to exterior surfaces only.

Removing dust and grease build-up on the motor housing assures proper motor cooling. Use caution and do not

allow water or solvents to enter the motor or bearings. Under no circumstances should motors or bearings be

sprayed with steam, water or solvents. The motor bearings are pre-lubricated and sealed, requiring no further

lubrication.

Burners and Orifices

Before each heating season, examine the burners and gas orifices to make sure they are clear of any debris such

as spider webs, etc. Clean burner as follows:

• Turn off both electrical and gas supplies to the unit.

• Disconnect union between manifold and gas valve.

• Remove manifold and burner assembly.

• Inspect and clean orifices and burners as necessary. Avoid using any hard or sharp instruments which

could cause damage to the orifices or burners.

- Remove any soot deposits from the burner with a wire brush.

- Clean the ports with an aerosol degreaser or compressed air.

- Wipe the inside of the burner clean. Cleaning the burner with a degreaser will slow the future buildup

of dirt.

• Before reinstalling the burner assembly, look down the heat exchanger tubes to make sure they are

clear of any debris.

• Reinstall manifold and burner assembly, reconnect wire leads, and gas supply piping.

• Turn on the electrical power and gas supply.

• Follow the start-up procedure (page 25) to light the burners and verify proper operation.

Heat Exchanger

The heat exchanger should be checked annually for cracks. If a crack is detected, the heat exchanger should be

replaced before the unit is put back into operation. Also, airflow across the heat exchanger should be checked to

make sure the blower is operating properly.

Flue Collector Box

The flue passageway and flue collector box should be inspected prior to each heating season and cleared of any

debris.

Electrical Wiring

The electrical wiring should be checked annually for loose connections or deterioration.

Replacement Parts

When ordering replacement parts, include the complete unit model number and serial number listed on the unit

rating plate.

CAUTION!!!

Turn off all gas and electrical power to the unit before

performing any maintenance or service operations to this unit.