9

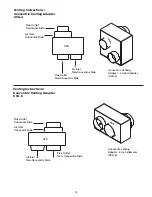

1. Installation of venting must conform with local

building codes. In the absence of local codes,

installation must conform with the National Fuel

Gas Code, ANSI Z223.1 or in Canada, CAN/CGA-

B149 installations codes.

2. The classification for vertical and horizontal venting

of all units is category III. The ANSI requirements

for vents classified as category III is that they must

be gas tight. Seal the joints with a metallic tape or

silastic suitable for temperatures up to 350 degrees

F. the venting system shall be installed in

accordance with these instructions.

3. All pipe is field supplied by others. For the vent

pipe, use pipe approved for a category III appliance

or single wall, 26 gauge or heavier galvanized vent

pipe. For the combustion air pipe on separated

combustion units, sealed single-wall galvanized air

pipe is recommended. Refer to the National Fuel

Gas Code for additional piping guidelines.

4. Select the vent and combustion air pipe size from

the tables (1) and (2) shown on the following pages.

Select the size of the vent and combustion air pipe

that fits the flue outlet and combustion air intake.

Use only the pipe size specified.

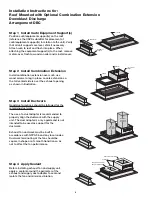

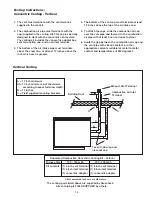

5. Install the vent and combustion air pipes with

minimum downward slopes (from the unit) of 1/4

inch per foot, suspend securely from overhead

structures at points no greater than 3 feet apart.

Fasten individual pipe lengths together with at least

three corrosion resistant sheet metal screws.

6. For the vent pipe, a minimum of 12 inches of

straight pipe is recommended at the flue outlet

before any elbows.

7. Avoid venting through unheated spaces if possible.

To minimize condensation, insulate any vent runs

greater than 5 feet that must pass through an

unheated space.

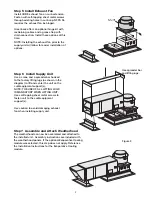

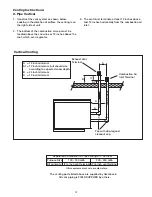

8. For the combustion air pipes, long runs in cold

climates may require insulation to prevent the

buildup of condensation on the outside of the pipes

where the pipe passes through heated spaces.

9. Vertical combustion air pipes should be fitted with a

tee with a drip leg and clean out cap to prevent any

moisture in the combustion air pipe from entering

the unit. The drip leg should be cleaned out

periodically during the heating season.

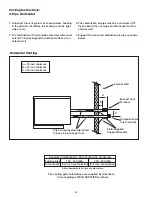

10.For separated combustion systems, the wall

thickness for the purpose of venting is 1 inch

minimum, 48 inches maximum.

• Standard Indoor Venting (uses building air for combustion)

• Separated Combustion Concentric Venting (uses outside air for combustion, one exterior roof or wall

penetration)

• Separated Combustion 2-Pipe Venting (uses outside air for combustion, two exterior roof or wall penetrations)

For each method, the units can be vented horizontally through an exterior wall or vertically through the roof.

Refer to the following pages for specific venting instructions. Construct the vent system for the selected

method, as shown in these instructions. When looking in the direction of airflow, the venting is on the right side

of the unit.

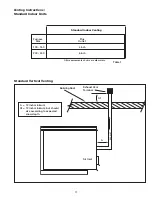

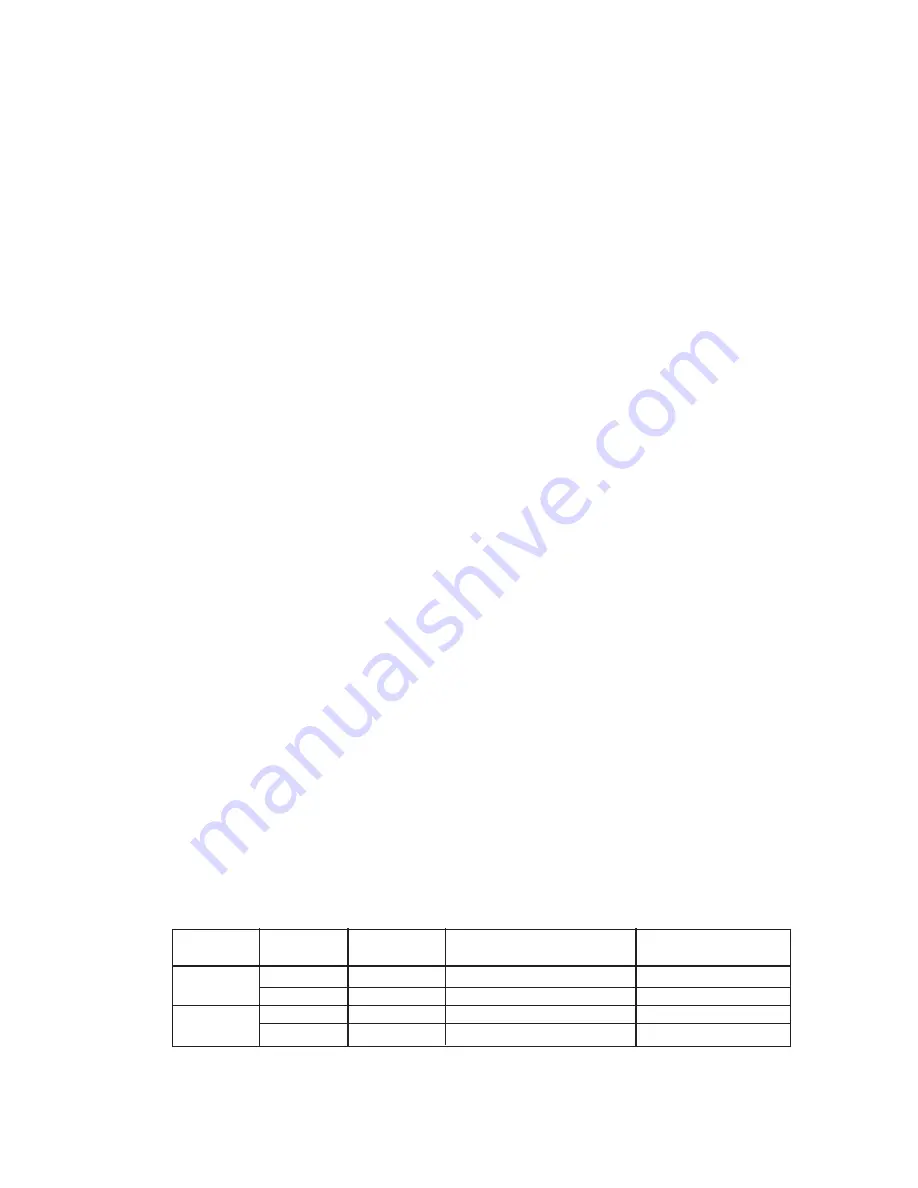

Furnace

Vent

Standard

Separated Combustion

Separated

Size

Lengths

Indoor

Concentric

Combustion 2-pipe

100 - 300

min

5 ft.

5 ft.

5 ft.

max

70 ft.

70 ft.

70 ft.

350 - 400

min

5 ft.

5 ft.

5 ft.

max

70 ft.

70 ft.

50 ft.

VENT LENGTHS FOR EXHAUST AND COMBUSTION AIR

Venting Instructions:

Indoor Units

Venting Methods for Indoor Units