Indirect Gas-Fired Heat Modules

10

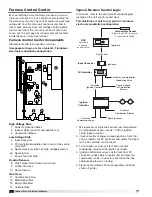

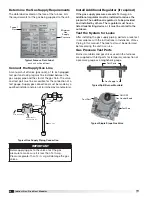

Install Exhaust Pipe

Slide the exhaust pipe through the CVA. Provide enough

exhaust piping to pass through the wall (or floor) and

provide the minimum clearance of 12 inches between

the exhaust pipe termination and the combustion air

intake. With all required clearances satisfied, attach the

exhaust pipe to the CVA.

Install Combustion Air Pipe

Attach a field-supplied combustion air pipe to the

concentric side of the CVA.

Be sure to provide enough combustion air piping

to pass through the wall and provide the minimum

clearance of 2 inches between the combustion air intake

and the exterior surface of the outside wall.

Be sure to maintain the minimum clearance of

12 inches between the exhaust pipe termination and the

combustion air intake.

Install CVA Assembl

y

Place the CVA assembly through the wall and verify

that all minimum clearance requirements as specified

in these instructions are met. Secure the CVA assembly

to the wall with corrosion-resistant sheet metal screws

through the mounting brackets.

Attach CVA Assembly to Unit

Attach the exhaust pipe to the unit’s combustion

exhaust. Using an additional combustion air pipe,

connect the unit’s combustion air supply intake to the

combustion air connection on the CVA.

Install Combustion Air Inlet Guard and

Exhaust Vent Terminal

Slide the combustion air inlet guard over the exhaust

pipe and fasten it to the combustion air pipe. Attach

the exhaust vent terminal to the discharge end of the

exhaust piping on the outside of the building.

Seal Opening

Seal the opening between the wall and the air intake

pipe using an appropriate method.

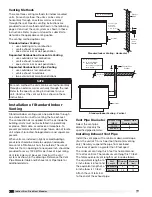

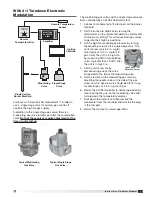

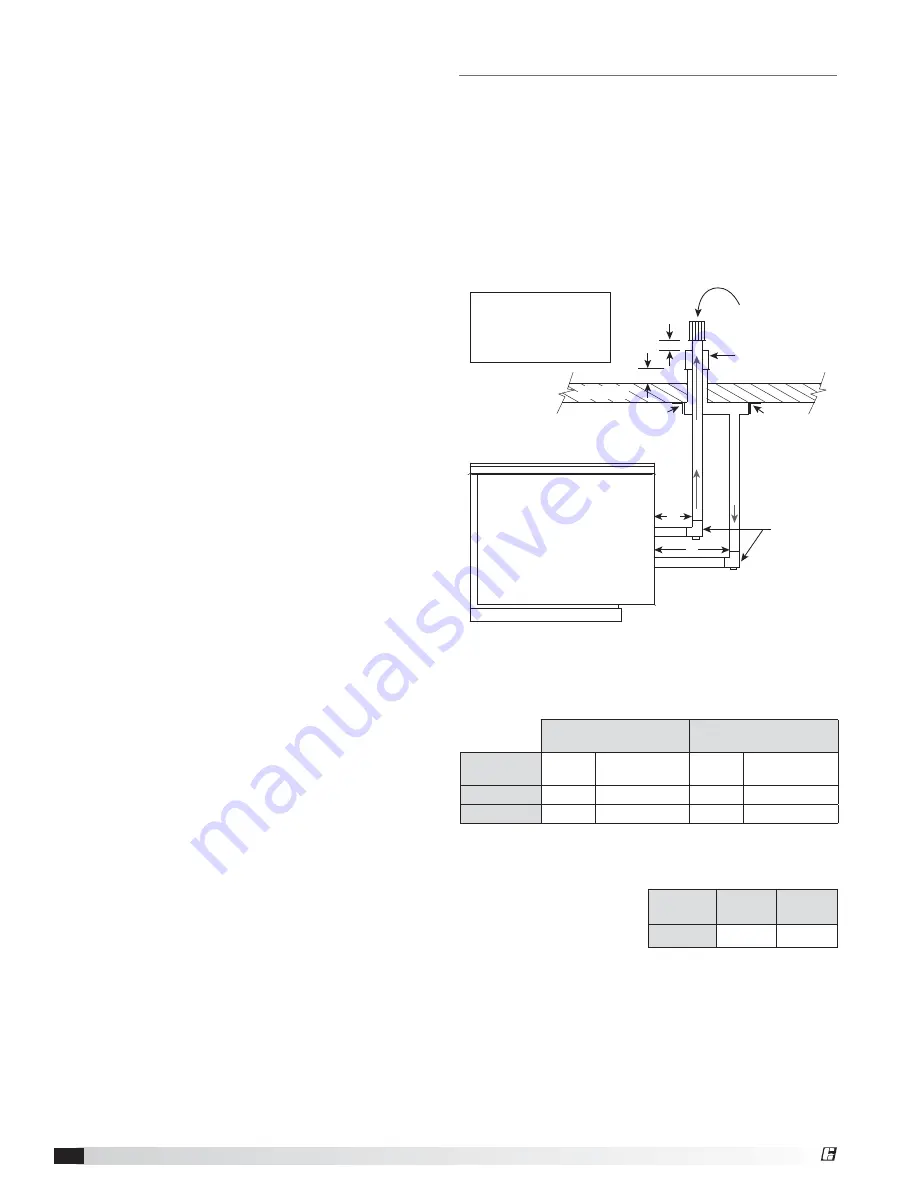

Concentric Venting – Vertical

Refer to the diagram below for venting on vertical

concentric systems. Maintain at least 12 inches

between the top of the combustion air inlet terminals

and the bottom of the exhaust terminal. (Dim. B).

The bottom of the combustion air intake pipe must

terminate above the snow line or at least 12 inches

above the roof, whichever is greater.

A tee with clean-out must be provided on the

combustion air and exhaust pipe to prevent debris from

entering the heat exchanger.

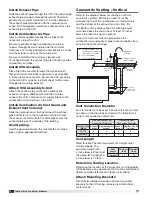

Vent Length

Refer to table. The total equivalent vent length must

include elbows. The

equivalent length of a

4 inch elbow is 6 feet and

the equivalent length of a

6 inch elbow is 10 feet.

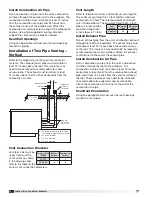

Determine Venting Location

Determine the location of the concentric venting adapter

(CVA) based on any clearances that must be maintained

(follow all codes referenced in these instructions).

Attach Mounting Brackets

Attach field-supplied corrosion-resistant mounting

brackets to the CVA using corrosion resistant sheet

metal screws.

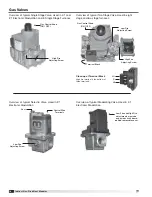

Vent Connection Diameter

Vent terminals must be used. Construct the vent system

as shown in the drawings and refer to the table for the

correct vent connection diameters.

Vent

Length

Minimum

(feet)

Maximum

(feet)

Vertical

10

70

A = 12 inch minimum, but

should size according to

expected snow depth

B = 12 inch minimum

C = 12 inch minimum

Roof Line

Exhaust Vent

Terminal

EXHAUST

COMBUSTION AIR

Combustion Air

Inlet Terminal

Mounting

Bracket

Tee with

drip leg and

clean-out cap

Mounting

Bracket

C

C

B

A

Non-Concentric Vent

Connection Diameter

Concentric Vent

Connection Diameter

Furnace Size

(MBH)

Exhaust

(inches)

Combustion Air

(inches)

Exhaust

(inches)

Combustion Air

(inches)

75-175

4

4

4

6

200-400

6

6

6

8

®