®

Document 453905

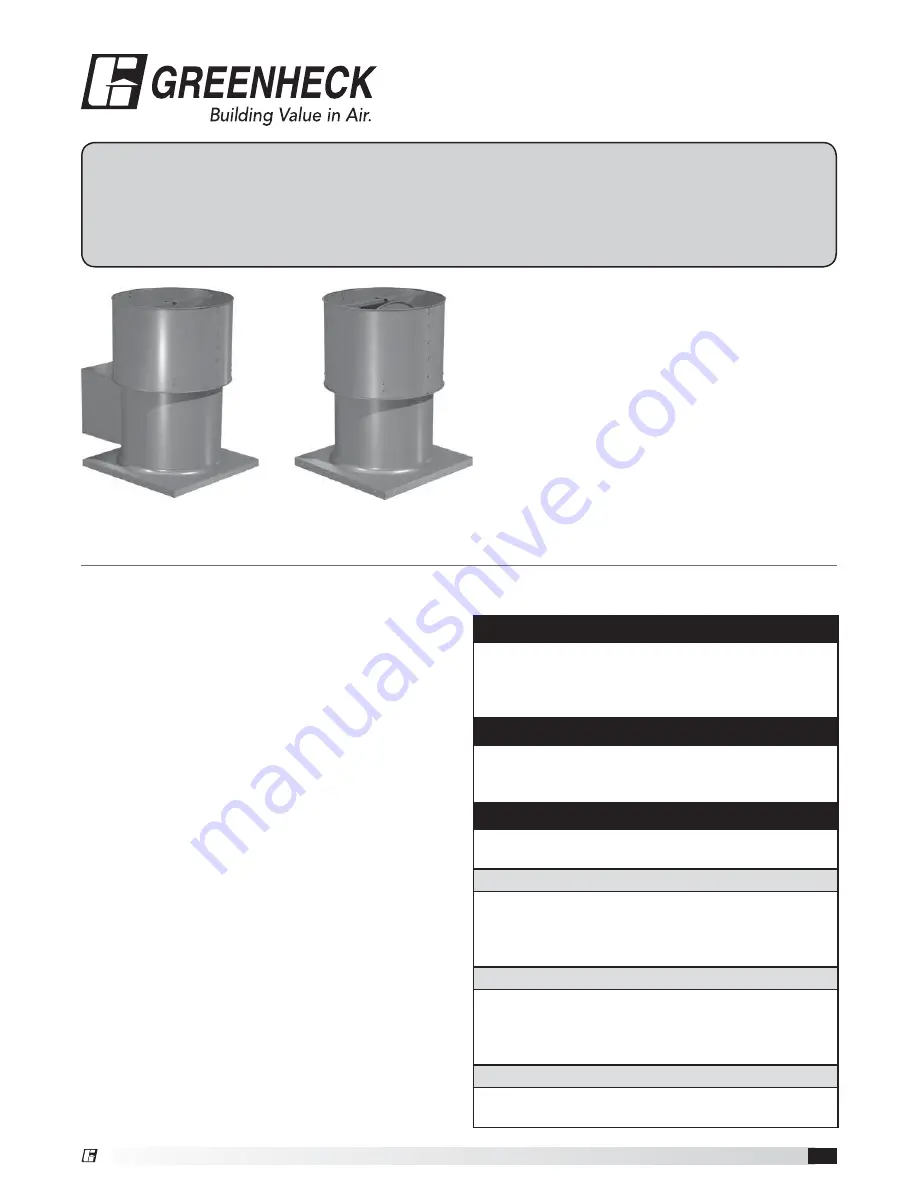

Models TAUD, TAUB-CA and TAUB

Tube Axial Upblast Fans

Tube Axial Upblast Fans

1

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with these instructions will result in voiding of the product warranty and may

result in personal injury and/or property damage.

Only qualified personnel should install this fan.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if seismic

activity is present. If more information is needed,

contact a licensed professional engineer before

moving forward.

1. Follow all local electrical and safety codes, as

well as the National Electrical Code (NEC) and the

National Fire Protection Agency (NFPA), where

applicable. Follow the Canadian Electric Code

(CEC) in Canada.

2. The rotation of the propeller is critical. It must

be free to rotate without striking or rubbing any

stationary objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan propeller faster than max

cataloged fan RPM. Adjustments to fan speed

with a Variable Frequency Drive (VFD) may affect

motor load. If the fan RPM is changed, the motor

current should be checked to make sure it is not

exceeding the motor nameplate amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

General Safety Information

TAUB

TAUD

DANGER

Always disconnect, lock and tag power source

before installing or servicing. Failure to disconnect

power source can result in fire, shock or serious

injury.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Precaution should be taken in explosive

atmospheres.

DANGER

Pour écarter les risques d’incendie, de choc

électrique ou de blessure grave, veiller à toujours

débrancher, verrouiller et étiqueter la source de

courant avant l’installation ou l’entretien.

ATTENTION

Lors de toute intervention sur la soufflante, le moteur

peut être suffisamment chaud pour provoquer

une douleur voire une blessure. Laisser le moteur

refroidir avant toute maintenance.

ATTENTION

Faire preuve de précaution dans les atmosphères

explosives.

7. Never open access doors to a duct while the fan is

running.