19

Laboratory Exhaust Systems

®

* Always check motor amps and compare to nameplate rating. Excessive fan speed may overload the motor and

result in motor failure. Do not exceed the maximum cataloged rpm of the fan.

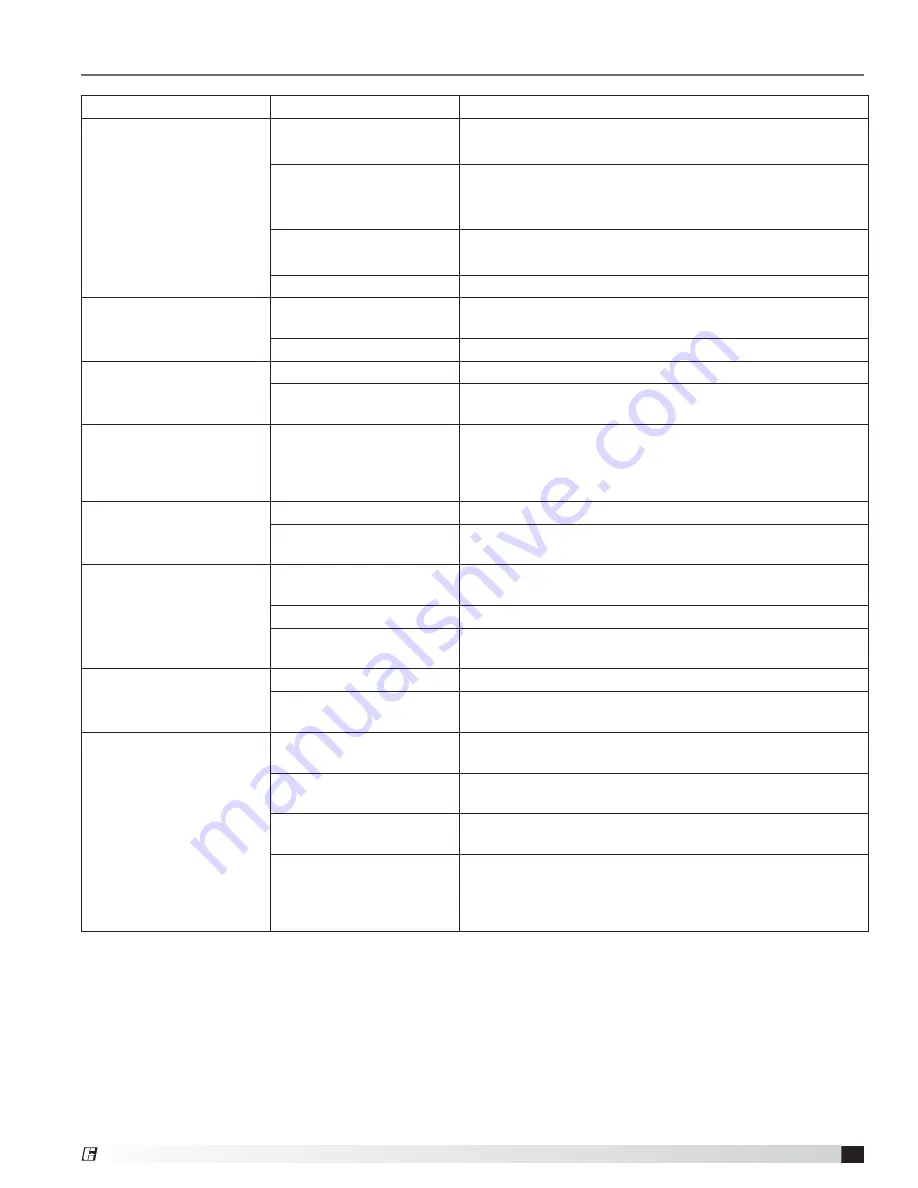

Troubleshooting

Problem

Cause

Corrective Action

Excessive

Noise

Wheel Rubbing Inlet

Adjust wheel and/or inlet cone.

Tighten wheel hub or bearing collars on shaft.

V-Belt Drive

Tighten sheaves on motor and fan shaft. Adjust belt

tension. Align sheaves properly (see procedure).

Replace worn belts or sheaves.

Bearings

Replace defective bearing(s). Lubricate bearings.

Tighten collars and fasteners.

Wheel Unbalance

Clean all dirt off wheel. Check wheel balance.

Low CFM

Fan

Check wheel for correct rotation. Check blade position of

BAP damper, increase fan speed.*

Duct System

Higher pressure than design. Filters need replacement.

High CFM

Fan

Decrease fan speed.

Duct System

Increase BAP damper blade open position. Resize

ductwork. Access door, filters, dampers not installed.

Static Pressure Wrong

Duct system has more

or less restriction than

anticipated

Remove obstructions in system. Use correction factor to

adjust for temperature/altitude. Adjust set point used to

control BAP damper modulation. Resize ductwork. Clean

filters/coils. Change fan speed.*

High Motor Amp Draw

Fan

Check rotation of wheel. Reduce fan speed.

Duct System

Resize ductwork. Check proper operation of isolation and

bypass dampers. Check filters and access doors.

Fan Doesn’t Operate

Electrical Supply

Check fuses/circuit breakers. Check for switches turned off

or disconnected. Check for correct supply voltage.

Drive

Check for broken belts. Tighten loose pulleys.

Motor

Assure motor is correct horsepower and not tripping

overload protector.

Overheated Bearing

Lubrication

Check for excessive or insufficient grease in the bearing.

Mechanical

Replace damaged bearing. Relieve excessive belt tension.

Align bearings. Check for bent shaft.

Excessive Vibration

Belts

Adjust tightness of belts. Replacement belts should be a

matched set.

System Unbalance

Check alignment of shaft, motor and pulleys. Check wheel

balance, rebalance if necessary.

Weak Roof or Support

Structure

Consult Structural Engineer to develop a plan to reinforce

building structure.

System Effect or High

Duct Velocities

Check inlet conditions and duct sizing to ensure duct

velocities are below 1500 fpm and transitions are smooth

and straight with 2-3 wheel diameters of length prior to

entrance to the fan system.