24

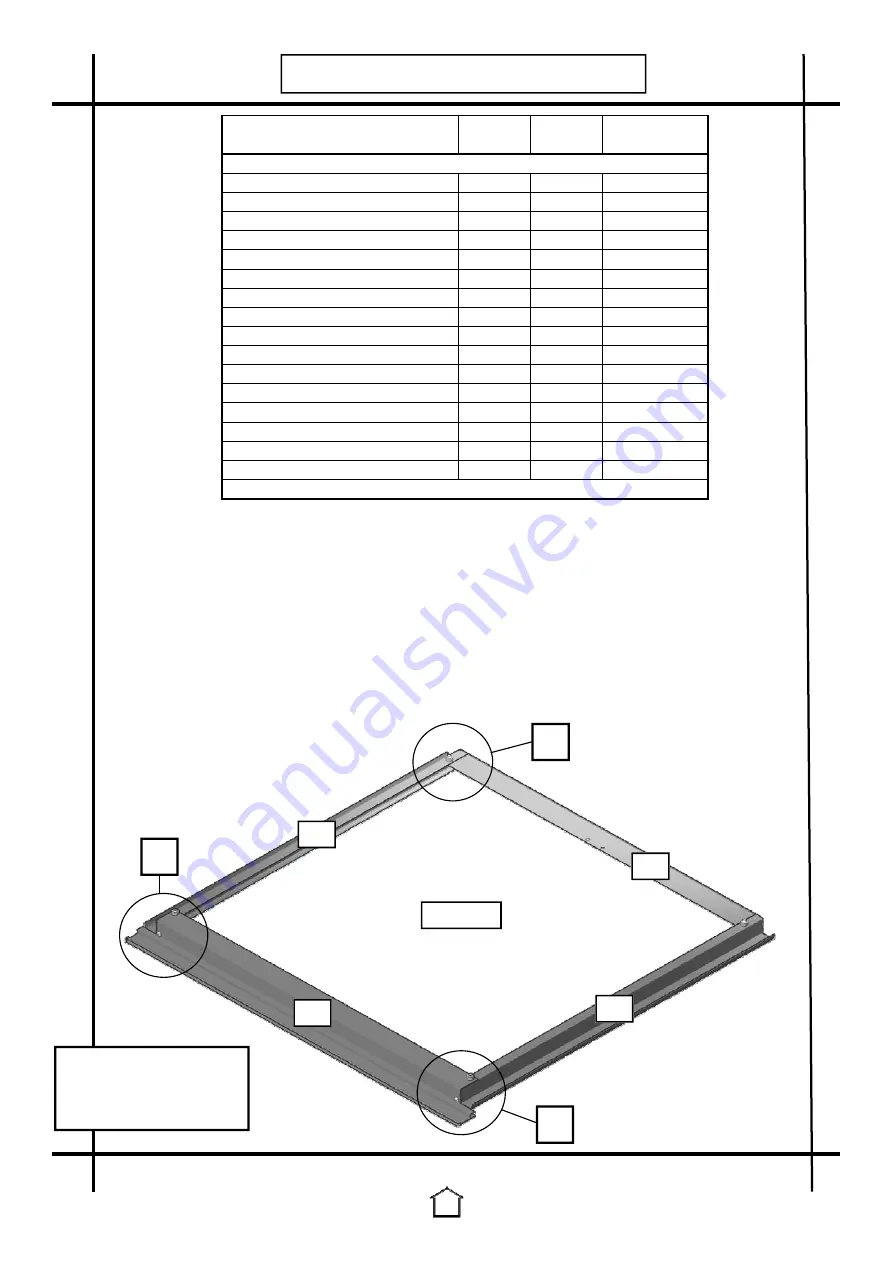

ROOF VENT ASSEMBLY

V

W

X

This image is a view of the

underside of the vent.

(This is the best position to

build the vent in).

540

541

541

543

610 X 610

Part Name

Part Length

Qty Required

No.

mm

\ vent

Casement stay*

330

-

1

Vent - bottom

540

590

1

Vent - side

541

604

2

Vent - slam bar

542

645

1

Vent - top

543

650

1

Bolt, square head - 10mm M6

576

10

4

Nut - M4*

578

-

6

Nut - M6

579

-

6

Nut caps

580

-

6

Screws, self tapping - 19mm M3.5

583

19

4

Silicone, gun

584

-

1

Silicone, tube

585

-

1

Screws, countersunk - 10mm M4*

587

10

6

Bolt, Cropped Head - 10mm M6

589

10

2

Vent peg assembly

709

-

2

Toughened Glass 610

-

610 X 610

1

*Redundant if an autovent is being used

1.

(Ignore step 1 if you are using an Autovent). Attach the casement stay to the vent bottom

using the M4 countersunk screws and nuts.

2.

Lay the components out so the underside of the vent is facing up. Lightly bolt the vent

sides to the vent top. (Diagram V & X)

3.

Now use the self tapping screws to screw through the vent top into the screw channel on

the vent sides. (Diagram V)

4.

Slide the 610 X 610 glass into the channels in the vent sides. Push the glass all the way up

the channels until it slots into the vent top. (Diagram W2)

5.

Bolt the vent bottom on to secure the glass. (Diagram W1)

6.

Now tighten all the bolts.

7.

Trim the end off the silicone tube. Run a bead of silicone all the way round edge of the

glass on the outside of the vent. This will help to reduce any leaks and will also secure the

glass.

8.

Repeat for each vent.

9.

The slam bar listed in the table

above is fitted during the vent

installation on page 34.