Greenlee / A Textron Company

2

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

960 PS Series Hydraulic Power Pumps

Table of Contents

Description, Safety, and Purpose .................................. 2

Important Safety Information ..................................... 3–4

Specifications ................................................................. 5

Setup .............................................................................. 6

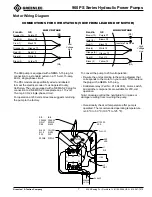

Motor Wiring Diagram .................................................... 7

Operation ....................................................................... 8

Maintenance and Service .............................................. 9

Troubleshooting ........................................................... 10

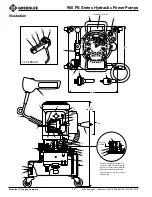

Illustrations ............................................................. 11–12

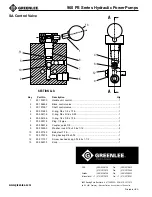

Parts List ................................................................ 13–14

Motor Parts List ............................................................ 15

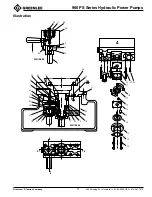

SA Control Valve ......................................................... 16

All specifications are nominal and may change as design improve-

ments occur. Greenlee Textron shall not be liable for damages

resulting from misapplication or misuse of its products.

Mobil DTE is a registered trademark of Mobil Oil Corporation.

KEEP THIS MANUAL

Description

The Greenlee 960 PS Series Hydraulic Pumps are

electrically powered, two-stage pumps that develop a

maximum of 689.5 bar (10,000 psi). The pumps are

intended to provide hydraulic power for an accessory

with a single-acting ram (hydraulic cylinder) such as a

Greenlee conduit bender or cable cutter.

Safety

Safety is essential in the use and maintenance of

Greenlee tools and equipment. This manual and any

markings on the tool provide information for avoiding

hazards and unsafe practices related to the use of this

tool. Observe all of the safety information provided.

Purpose of this Manual

This manual is intended to familiarize all personnel with

the safe operation and maintenance procedures for the

following Greenlee tools:

960 PS Series Hydraulic Pumps

Keep this manual available to all personnel.

Replacement manuals are available upon request at no

charge.

Fill unit with hydraulic oil before

operating pump.

Failure to fill unit with oil will result in

damage to the pump.