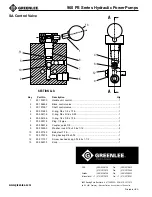

Greenlee / A Textron Company

8

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

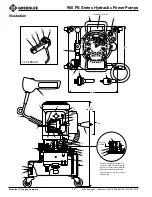

960 PS Series Hydraulic Power Pumps

Operation

Do not use this pump in a hazardous

environment. Hazards include

flammable liquids, gases, or other

materials. Using this pump in a

hazardous environment can result in

a fire or explosion.

Failure to observe these warnings

will result in severe injury or death.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection can

result in serious eye injury from

flying debris or hydraulic oil.

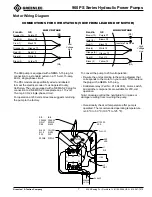

Procedure for depressurizing the hydraulic system:

1.

Disconnect the pump from the power source.

2.

Rotate the release lever clockwise.

3.

Disconnect the hose slowly to release any

trapped pressure.

Changing Accessories

Before changing the hydraulic accessory that is

connected to the pump, follow this procedure for

depressurizing the system.

Note: Starting the motor without a tool attached to the

pump will cause the pump to immediately build an

internal pressure of 689.5 bar (10,000 psi).

If this happens, shut off the pump and turn the valve

lever clockwise to release the hydraulic pressure.

1.

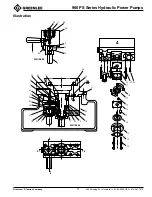

Move release valve lever clockwise.

2.

Check reservoir oil level. The oil level should be

within 13 mm (1/2") of the top of the reservoir.

If oil level is too low, refer to “Adding Oil” under

“Maintenance and Service” in this manual.

3.

Turn the dipstick two turns counterclockwise.

Note: Operating the pump without loosening the

dipstick will result in poor pump performance.

4.

Connect the pump to an appropriate power supply.

5.

Start motor and allow pump to idle for a few minutes.

This will allow the hydraulic fluid to work through the

system and prime the pump.

6.

Stop the motor. Turn the lever counterclockwise.

7.

Start the motor to advance the hydraulic ram. When

finished, stop the motor. Turn the lever clockwise to

release the pressure.

Note: Starting the pump while the lever is in the

clockwise position may cause the ram to extend.

Turning the lever counterclockwise while the pump is

running may release the pressure.

8.

During periods of heavy use, occasionally stop the

pump and check the oil temperature. The recom-

mended operating temperature is 38

°

C to 50

°

C

(100

°

F to 125

°

F).

9.

Tighten the dipstick.