C3 Auto Whip Clad Cable Cutter

Greenlee Tools, Inc.

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

16

Operation

(con’t)

Figure 16

Figure 17

Securely fasten the spindle to the two stands and

secure the two stands from moving. Cable leaving

the inside of the coil may be twisted and cause the

roller, spindle, and stands to tip over as the cutting

machine pulls the cable.

6. Raise the tensioning lever (10) to remove tension

between the feed rollers.

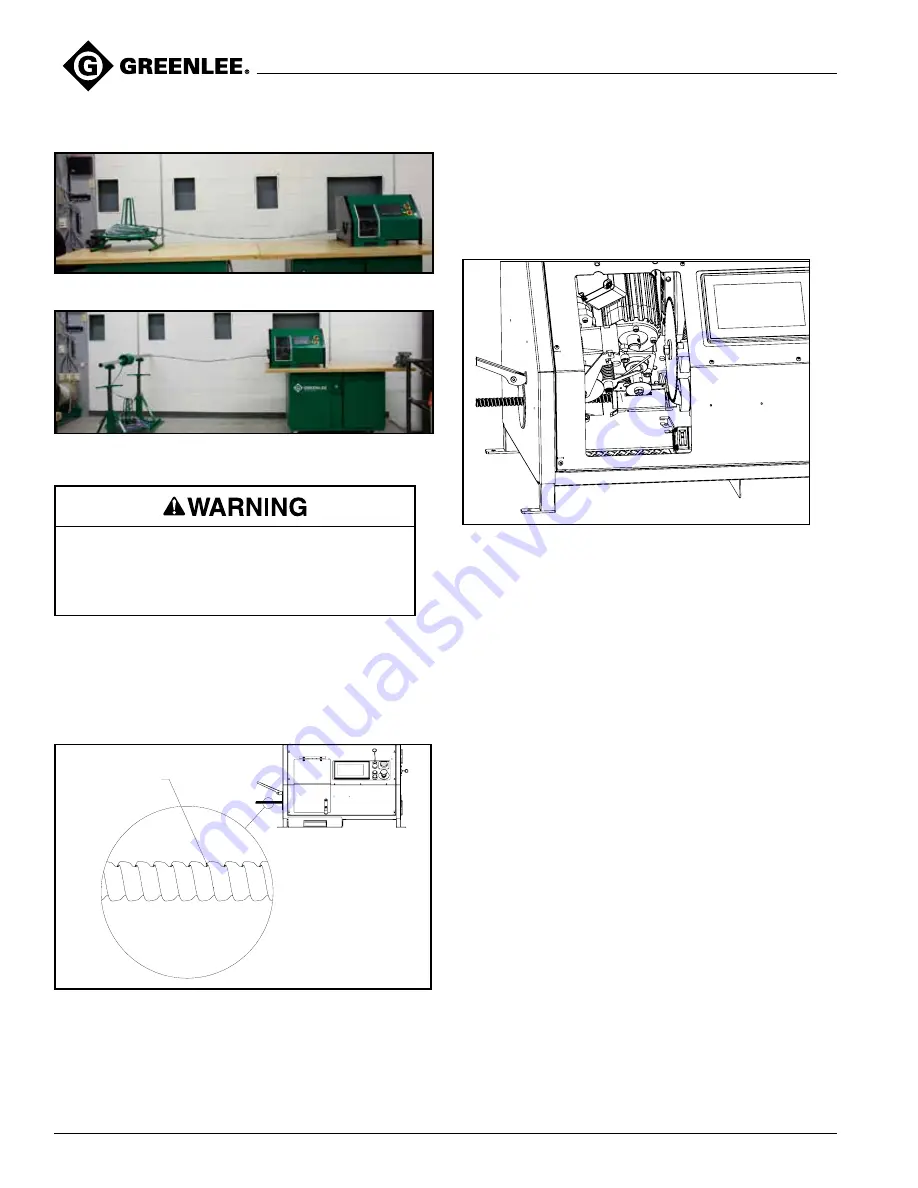

7. Examine and orient the MC cable, so the seam on

the armor is toward the tailing edge when the cable

is feed into the machine (see figure 18).

SEAM ON ARMOR

IS ON TAILING SIDE

Figure 18

8. Feed the cable into the input horn (11) on the left

side of the machine, between the two feed rollers,

between the notch clamping plate and V-shaped

support and stop when the end of the cable is flush

with the cut off blade (see figure 19).

a. The cable goes over the rubber feed roller

b. The cable goes across the V shaped

notching support

c. The cable end is flush with the 7-1/4” Cut Off

Saw Blade.

Figure 19

9. When loading large diameter cables, it will be

necessary to press the

Load Cable

button. This will

move the blades up to their highest position so that

the cable can be fed through without obstructions.

When the Load Cable button is pressed the button

will turn yellow to indicate that the motors are

returning to their home position and then the button

will turn green to indicate that the motors have

reached their home position.

10. If necessary, open the clear access door (8) to

help feed the MC cable. See instructions for

Access Door.

11. Lower the lever to apply tension to the feed rollers.

Lowering the lever will provide the sufficient force

on the steel guide roller to clamp the cable against

the rubber feed roller.

12. Close the access door (8) if open and check that the

switch key is fully engaged.

Note: Inspect the whip length, lead length, tail length,

notch depth, and notch length for accuracy.

1

2

3

4

1

2

3

4

D

C

B

D

C

B

A

5

- NOTICE -

This drawing is the property of Greenlee and

embodies a confidential proprietary design in which

Greenlee retains all patents, patents pending and

other rights, including exclusive right of use,

manufacture and sale. It is submitted under a

CONFIDENTIAL relationship for a specific purpose

and the recipient agrees, by accepting this drawing

and information, not to supply or disclose any

information regarding it to any unauthorized person.

Nor may any part of it be copied, exhibited or

furnished to others, nor may photographs be taken of

any article fabricated or assembled from this drawing

without the consent of Greenlee. This drawing must

be returned on request.

C 2016 GREENLEE TEXTRON

GREENLEE TEXTRON INC. IS A SUBSIDIARY OF TEXTRON INC.

(PRODUCT, CATALOG NUMBER)

DRAWING UNITS

INCH

THIRD ANGLE

PROJECTION

DO NOT SCALE DRAWING

OLD NO.

00

DATE

1:3

REV.

C

SIZE

SIMILAR TO

DRAWN BY

SCALE

CAGE CODE

PRINT & MFG NO.

INITIAL USE:

PART NAME / TITLE

- MATERIAL -

SHEET 4 OF 4

52081125_extra views

GEOMETRIC DIMENSIONING & TOLERANCING PER ASME Y14.5M

TOLERANCES UNLESS OTHERWISE SPECIFIED

REV

DESCRIPTION

BY

DATE

ECO NO. ENGINEER

INCH TOLERANCES

.XX = ± .03

.XXX = ± .010

ANGLES = ± 0° 30'

DEBURR HOLES AND SHARP EDGES

A

5

HEAT TREAT