Greenlee Textron / Subsidiary of Textron Inc.

14

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

HG3505A / 42303 Portable Power Unit

Note: During disassembly, take special note of the

position of the wear plate (5) and pressure

loading seals (6 & 14). The open side of the

seals should be toward the inlet side of pump.

The gear contact pattern in the bore is additional

identification of the inlet side.

9.

Invert pump body with shaft seal (8) up. Remove

shaft seal by prying it out with a large screwdriver.

Damaging the shaft seal bore will result in seal

leakage.

10. Wash all parts and dry thoroughly.

11. Inspect wear plate (5) and replace if scoring or

uneven wear is observed. A somewhat heavier

wear pattern is normal on the inlet side of the wear

plate, but there should be no heavy scoring in this

area.

12. Inspect bushings in body and cover. Replace cover

or body if bushings are heavily scored or burned.

13. Inspect gear journals and faces. Replace if faces or

journals are scored or worn, or if shaft journal wear

exceeds 0.001 inch (.025 mm).

Disassembly

Pump disassembly should be done only if trouble-

shooting indicates that the pump is not operating

properly. Overhaul pump only in a clean, dust-free

location, using clean tools and equipment. Dirt or grit

will damage the highly machined surfaces and will result

in leakage or premature failure of the pump.

Before beginning disassembly, scribe a mark on inlet

side of the body and the cover to insure that the pump

will be reassembled in the same manner as it was

shipped from the factory. If the body or the cover is

replaced during overhaul, scribe a mark on the new part

in the same location as the mark on the part it replaces.

Reference numbers refer to items illustrations listed.

1.

See Exploded View, HG3505 Power Unit. Drain

the hydraulic system and remove reservoir. Filter

should be removed and cleaned whenever reservoir

is removed. Loosen nut of male connector (9) and

turn tube (27) aside. Remove baffle (30).

Note: Do not adjust the hex nuts and washers located

on studs (29).

2.

Remove swivel nut of hose assembly (32) from

elbow (33), leaving elbow in place. Remove hex

head cap screws (19) and washers from pump

flanges. Spacers (18) may fall free. Loosen set

screw (16) which secures the pump shaft to the

coupler (15). It is not necessary to loosen the two

set screws (16) which secure the engine output

shaft to the coupler. Remove pump from power unit.

3.

See Exploded View, Pump. Clean outside of pump

with a good grade solvent and dry thoroughly.

4.

Remove Woodruff key (9) from drive shaft. Using a

file or stone, remove any burrs from shaft end or

keyway. Grease keyway before sliding drive shaft

through shaft seal.

5.

Secure pump in vise with shaft end down, using

light clamping pressure. Remove cap screws (1)

and washers (2). Remove pump from vise.

6.

When separating the body from the cover, use one

hand to support cover from underneath, since cover

and internal parts will drop suddenly when dowel

pins are disengaged. Separate cover (10) from

body (13) by supporting pump, shaft end up, on the

mounting flanges and pressing on end of drive shaft

with an arbor press. OR use two large screwdrivers

to pry in the indented areas between body and

cover, OR tap drive shaft lightly with a plastic mallet.

Note: Do not insert screwdrivers further into the pump

than the depth of the indentations. Any burrs or

scratches must be removed from the body and/or

cover after this procedure to assure a good seal

between body and cover.

7.

Holding pump with shaft end down, remove cover

(10). Dowel pins (7) and seal ring (4) may remain

either in the body or cover.

8.

Lift out; driven gear (11), drive gear (12), and wear

plate (5).

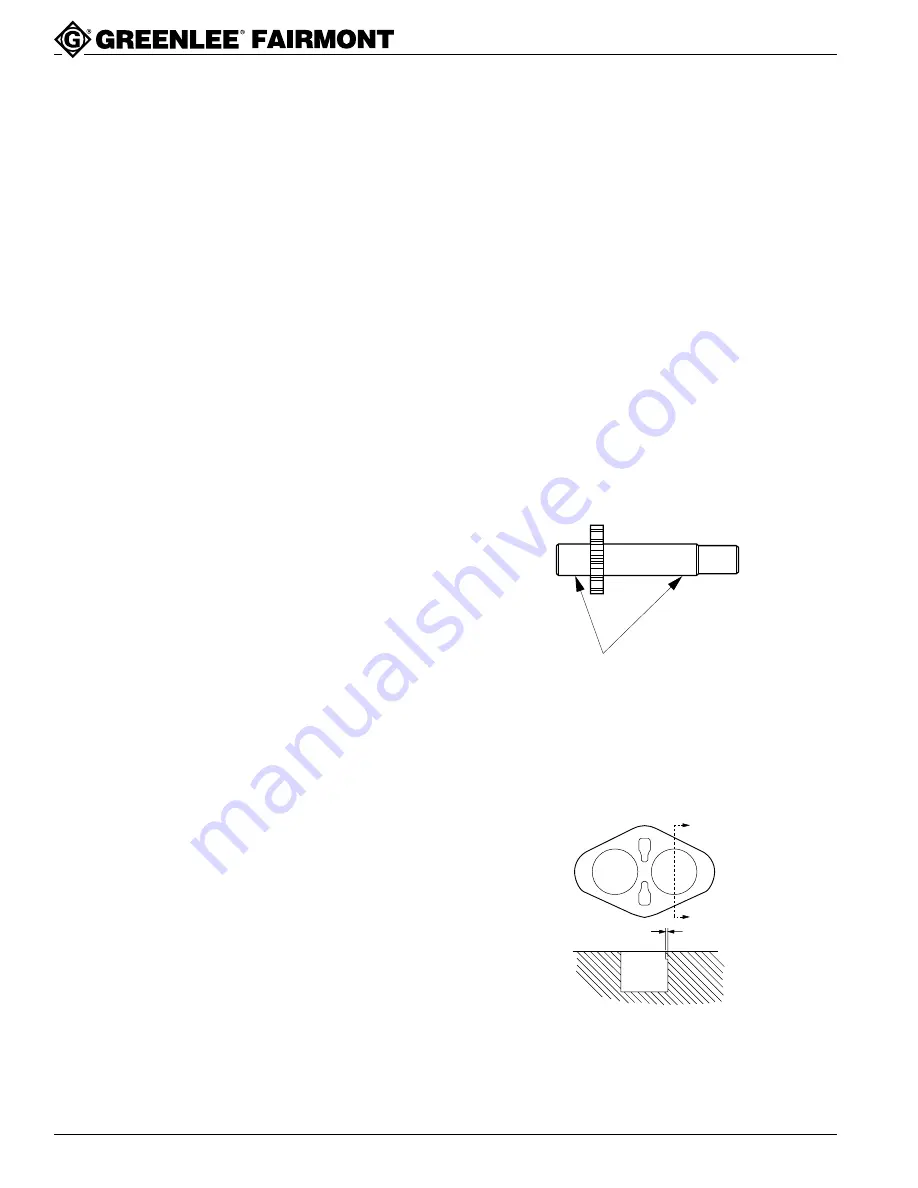

JOURNAL WEAR IN

BEARING AREA

14. Inspect body for wear and scoring. If gear contact

wear on the inlet side exceeds 0.005 inch (.127

mm), replace body. If the body is usable, remove

any burrs with suitable burring tool.

A

A

IN

OUT

.005

SECTION A-A