GREENLEE

FAIRMONT

HG3558B/42307 Portable Power Unit

Greenlee Textron / Subsidiary of Textron Inc.

9

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

4

5

2

3

6

1

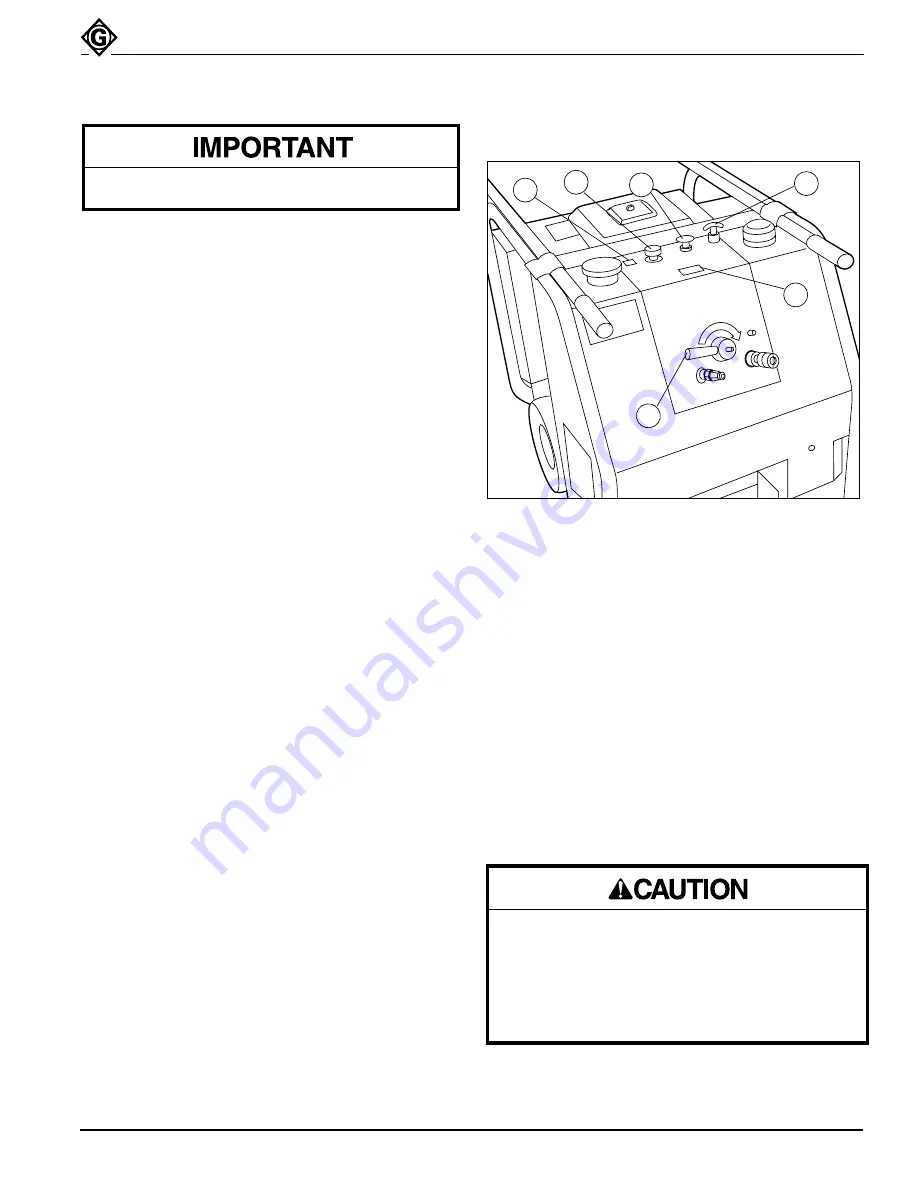

Figure 4

Power Unit Controls

Position the power unit on firm level ground.

Operation (cont’d)

Use appropriate lifting equipment. Make sure all

components used to lift this power unit are rated for

300 lbs (135 kg) and are securely attached between

the power unit and lifting equipment. Inadequate

components may fail and cause the power unit to

fall, resulting in injury or property damage.

Pre-Start

1.

Check engine oil level. Refer to engine Operating

and Maintenance Instructions for correct oil type

and checking instructions.

2.

Check fuel level. Refer to engine Operating and

Maintenance Instructions for fuel recommendations.

3.

Check hydraulic reservoir oil level. Fill to FULL mark

on dipstick. See Maintenance. See Recommended

Hydraulic Fluids for correct hydraulic fluid.

4.

Verify that all current maintenance has been per-

formed on the power unit. See Maintenance.

5.

Connect the tool hoses and tool to the power unit.

See Hose Connections.

Starting the Power Unit (See Figure 4)

1.

Move the flow ON / OFF lever (1) to the OFF

position.

2.

Pull out the choke knob (2).

Note: A warm engine requires less choking than a cold

engine.

3.

Pull throttle T-handle (3) out to the fully open posi-

tion. Rotate T-handle clockwise to lock in position

and counterclockwise to unlock from position.

4.

Move switch (4) to the ON position.

5.

Depress starter button (5) to start engine.

Note: The best starter life is provided by using short

starting cycles of several seconds. Prolonged

cranking, more than 15 seconds per minute, can

damage the starter motor.

6.

After the engine has started, reduce engine RPM.

Slowly open choke.

7.

Move flow ON / OFF lever (1) to the ON position.

8.

It is recommended that the power unit be allowed to

run (idle) for a few minutes to warm the hydraulic

reservoir fluid. Actuating the tool intermittently will

reduce the time required to warm the fluid to an

efficient operating temperature.

9.

Using the engine throttle T-handle (1), adjust the

engine RPM to obtain the rated hydraulic oil flow,

5 to 8 GPM. See flow meter (6). Lock the T-handle

throttle in position. DO NOT EXCEED THE MAXI-

MUM ALLOWABLE FLOW RATE FOR THE TOOL

BEING USED WITH THE POWER UNIT. Exceeding

the tool’s maximum flow rate could cause tool

failure and personal injury. See your tool operator’s

manual for proper flow rate.

Stopping the Power Unit (See Figure 4)

1.

Move the flow ON/OFF lever (1) to the OFF

position. Idle the power unit engine for a few

moments. Move switch (4) to the OFF position.

2.

Disconnect the tool hoses from the power unit.

See Hose Connections.

Retractable Handles

The handles on the power unit can be extended when

transporting the power unit or retracted for convenience

when connecting/disconnecting tool hoses, starting

power unit, etc. To use the handles in the extended

position for transport, pull the handles fully out. Rotate

the handles, locking the pins on the handles into the

slots in the cover of the power unit.

Lifting the Power Unit

Stop the power unit engine before lifting. Take care

when attaching the lifting device (chain, strap, etc.) so

as not to damage the power unit.