Greenlee / A Textron Company

7

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

CK1240 and CK1240C Crimping Tools

Operation

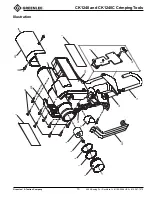

1. Clean the die seat area.

2. Install the proper size and type of crimping dies.

3. Press the release button on the C-head and slide

one of the die halves into the jaw. Release the

button and slide the die half until the retainer snaps

and locks the die into place.

4. Press the release button on the ram body (located in

the cutout) and slide the other die half in. Release

the button and slide the die half until the retainer

snaps and locks the die into place.

5. Follow the connector manufacturer’s instructions

for appropriate cable strip length and surface

preparation.

6. Insert cable fully into connector and center the

connector between the dies.

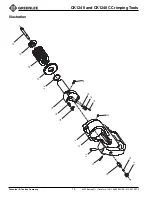

CRIMPING DIRECTION

1ST COMPRESSION

CRIMPING DIRECTION

SIDE A

CRIMPING DIRECTION

SIDE B

1ST COMPRESSION

SIDE A

1ST COMPRESSION

SIDE B

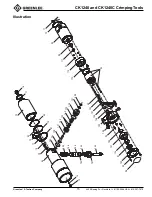

7. Using the sequence illustrated here, press the

trigger to advance the dies. Continue to crimp until

the pressure relief valve activates.

Note: Pressure relief occurs at approximately

106 kN (12 tons) and is indicated by an audible “pop.”

8. After achieving pressure relief, the ram automatically

returns to the start position and the dies retract.

9. When using KC12-type dies, complete the number

of crimps listed on the “Connector Selection” chart in

this manual. For other dies, complete the number of

crimps specified by the manufacturer.

10. Remove the connector from the crimping tool.

Note: After completing the last crimp on an aluminum

connector, wipe off the excess oxide inhibitor.

Pinch points:

Keep hands away from the crimping

tool head when crimping.

Failure to observe this warning could

result in severe injury or death.

Electric shock hazard:

This tool is not insulated. When

using this unit on or near energized

electrical lines, use proper personal

protective equipment.

Failure to observe this warning could

result in severe injury or death.

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection could

result in serious eye injury from

flying debris or hydraulic oil.

Skin injection hazard:

Do not use hands to check for oil

leaks. Oil under pressure easily

punctures skin. If injured, seek

medical attention immediately to

remove oil.

Failure to observe this warning could

result in serious injury, gangrene, or

death.

An incomplete crimp can cause a fire.

• Use proper die, connector, and cable combina-

tions. Improper combinations can result in an

incomplete crimp.

• An audible “pop” indicates that the crimping tool

has achieved a complete crimp. If you do not

hear a “pop,” the crimp is incomplete.

Failure to observe these warnings could result in

severe injury or death.