Greenlee Textron / Subsidiary of Textron Inc.

10

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

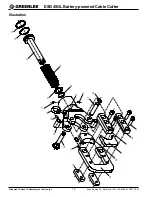

ESG45GL Battery-powered Cable Cutter

Motor / Gearbox / Bearing Reassembly

1. Install two fillister head screws (112) into spacer

(not numbered) and motor (90). Tighten screws.

2. Install four screws (not numbered) into gear housing

(94). Tighten screws.

3. Install four screws (93) into mounting block (109)

and gear housing (94). Tighten screws.

4. Replace grooved ball bearing (101) and snap ring

(100) subassembly.

5. Replace eccentric (103). Use a fiber mallet to tap

eccentric onto shaft. Replace ball bearing (91).

6. Align end cap (102). Use a fiber mallet to tap cover

until it is flush on mounting block (109). Install two

screws (92).

7. Align gear housing / motor subassembly so that the

pump piston (152) extends through the mounting

block (109) and makes contact with the grooved

bearing (101). Locate and start the screws (108)

through the mounting block and into the pump

housing. Tighten the screws.

Pump Subassembly

8. Insert pump piston (152) into pump housing.

Be sure to replace O-ring (153).

9. Insert seal (122) and unloading valve assembly into

pump housing. Grasp needle valve subassembly by

the pressure relief (126) and twist it several turns

clockwise. Stop when the mark or piece of tape is

facing up.

10. Assemble pump piston (150), valve stem (156),

spring (155) and screw plug (151). Be sure to

replace sealing washer (154). Torque screw plug

(151) to 75 foot-pounds.

11. Install release lever (107) so that the forked end

engages the unloading valve subassembly between

the pressure relief (126) and the support ring (127).

Install screw (99) and washer (104).

12. Insert threaded bushing (79) and feed tube sub-

assembly (77, 78, 82). Screw in until snug.

13. Install reservoir (74). Slip the O-ring (80) over the

reservoir. Using a hooked tool, carefully slip the

O-ring over the lip of the pump housing.

14. Insert the plug (76) into the reservoir.

Misc. Components Reassembly

15. Remove the protective plastic bag from the elec-

tronics subassembly. Insert the LED into the LED

bushing (59).

16. Lay the gear housing / motor subassembly into the

right half of the housing. Insert the circuit board into

the circuit board slot, so that the wires and chip face

in the direction of the trigger.

17. Lay the wires into case. Be sure that the wires will

not be pinched.

18. Guide the wires for the battery clip so the battery

wires lay on top of the electronics box; install the

battery clip so the red wire is upward.

19. Install the trigger cover (53) and plug (60). Depress

and release the trigger to be sure that it operates

freely.

20. Locate the right housing half on top of the left

housing half. Check for pinched wires.

21. Install the housing screws (51, 56-58).

Note: Handle screw (51) must engage the nut (52).

22. Install the piston (21).

23. Install the spring (18).

24. Replace the front head assembly. Twist the cutting

head base (30) until it stops; back off 3/4 of a turn

and tighten the screws (17). Be sure that the cutting

head assembly rotates freely approximately 350

°

.

25. Install the cutting blade (26). Insert the pin (31)

through the ram.

26. Clamp the head assembly into a vise with the

reservoir plug facing upward. Remove the fill plug

(76) and fill the reservoir with hydraulic oil.

27. Install the battery.

28. Squeeze the trigger while depressing the release

lever for 45–60 seconds. Fill the reservoir with

hydraulic oil. Replace the fill plug (76).

29. Replace the tank cover and tank cover screws (55).

Reassembly