Greenlee Textron / Subsidiary of Textron Inc.

6

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

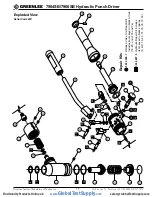

7904SB/7906SB Hydraulic Punch Driver

123456

123456

123456

123456

123456

1234

1234

1234

1234

123456789012345

123456789012345

123456789012345

123456789012345

12345678901

12345678901

12345678901

12345678901

12345678901

12345678901

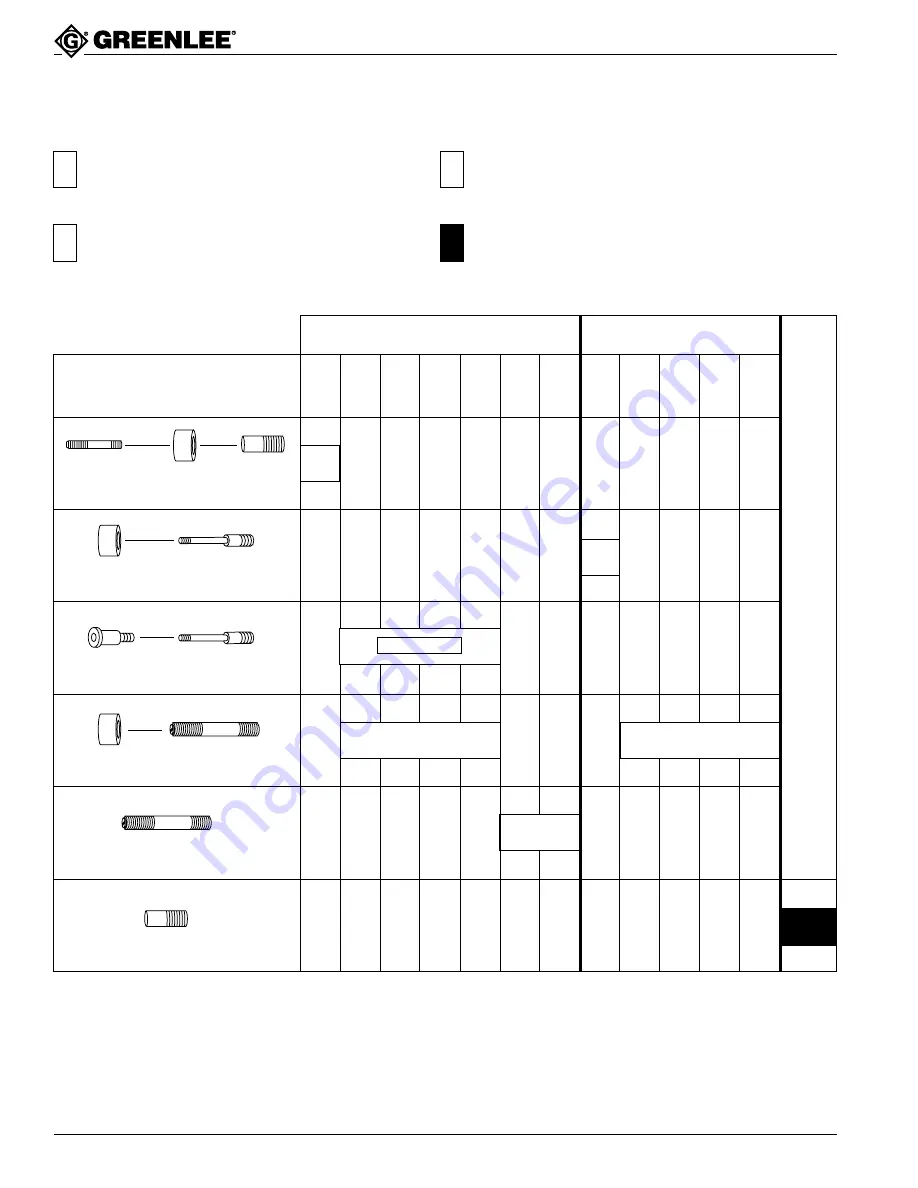

Capacity and Draw Stud Selection Guide

1614SS

DRAW STUD

1924AA

SPACER

33967

ADAPTER

1924AA

SPACER

29451

7/16" DRAW STUD

29451

7/16" DRAW STUD

31874

ADAPTER

1924AA

SPACER

31872

3/4" DRAW STUD

31872

3/4" DRAW STUD

33967

ADAPTER

Stud and Accessories

1/2"

con.

ø 0.885"

15.2 mm

3/4"

con.

ø 1.115"

28.3 mm

1-7/32"

1"

con.

ø 1.362"

34.6 mm

1-1/4"

con.

ø 1.701"

43.2 mm

1-1/2"

con.

ø 1.951"

49.6 mm

2"

con.

ø 2.416"

61.5 mm

1/2"

con.

ø 0.885"

15.2 mm

3/4"

con.

ø 1.115"

28.3 mm

1-7/32"

1"

con.

ø 1.362"

34.6 mm

1-1/4"

con.

ø 1.701"

43.2 mm

Electronic Connector Punches

RS-232, 229, 231, 234, 238.

Standard & Slug-Buster

®

Punches

Slug-Splitters

®

12345678901234567890123456789

12345678901234567890123456789

12345678901234567890123456789

12345678901234567890123456789

12345678901234567890123456789

12345678901234567890123456789

12345678901234567890123456789

12345678901234567890123456789

1234567890123456789012

1234567890123456789012

1234567890123456789012

1234567890123456789012

1234567890123456789012

See Note

➁

See Note

➀

➀

The Slug-Buster

®

punches may not split the slug when used with this adapter, because of the smaller pilot hole.

➁

The 31874 step-saver adapter and 29451 draw stud are included with the 7804SB only.

They may be purchased separately and used with any Quick-Draw™ hydraulic punch driver kit.

See Note

➁

12345

12345

12345

12345

12345

12345

12345

12345

123

123

123

123

123

1234

1234

1234

1234

1234

14 Ga. (0.0747" [1.9 mm])

Mild Steel

10 Ga. (0.1345" [3.4 mm])

Mild Steel

10 Ga. (0.1345" [3.4 mm])

Stainless Steel

16 Ga. (0.0598" [1.5 mm])

Mild Steel & 1/18" Soft Aluminum

www.

GlobalTestSupply

.com

Find Quality Products Online at:

sales@GlobalTestSupply.com