8

MOMENTUM T7 TREADMILL

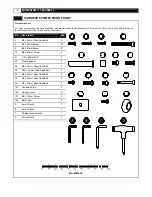

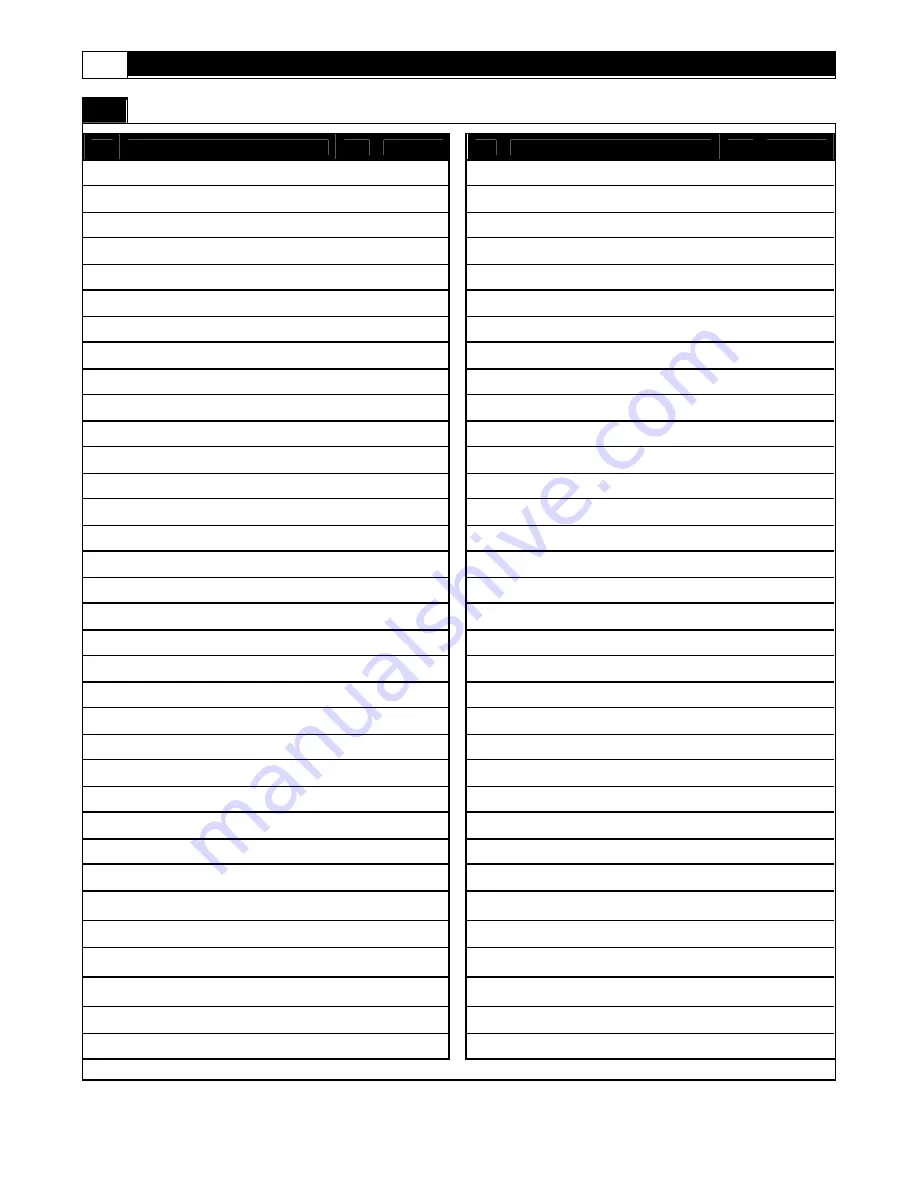

PARTS LIST

No.

Description

Qty. Order No.

No. Description

Qty. Order No.

69

Driv ing Motor

1

T7 - 069

103 #8 x 35mm Screw

4

T7 - 103

70

Roller Carbon Brush

1

T7 - 070

104 Console Screw

2

T7 - 104

71

Motor Holder

1

T7 - 071

105 Handlebar Fixing Plate

2

T7 - 105

72

Motor Holder Adjustment

1

T7 - 072

106 Upright Cov er

2

T7 - 106

73

M10 x 136mm Bolt

1

T7 - 073

107 M6 x 15mm Screw

2

T7 - 107

74

M10 x 63mm Bolt

1

T7 - 074

108 Front Handle bar

1

T7 - 108

75

Motor Driv e Belt

1

T7 - 075

109 Metal Cap

3

T7 - 109

76

Tension Wheel Bracket

1

T7 - 076

110 M8 x 45mm Bolt

12

T7 - 110

77

Transf er Board

1

T7 - 077

111 Emergency Stop

1

T7 - 111

78

Front Roller

1

T7 - 078

112 Hand Pulse Sensor Wire - Upper

2

T7 - 112

79

Front Roller Shaft

1

T7 - 079

113 Side Rail Guide Light Board

1

T7 - 113

80

Deck Frame

1

T7 - 080

114 N/A

81

Micro Switch

1

T7 - 081

115 N/A

82

M8 x 70mm Bolt

3

T7 - 082

116 Handle Bar Plastic Bushing

2

T7 - 116

83

8 x 16 x T2.0 Washer

13

T7 - 083

117 Motor Control Board

1

T7 - 117

84

Motor Hood Side Cover - Left

1

T7 - 084

118 Motor Control Board Fan

1

T7 - 118

85

Motor Hood Side Cover - Right

1

T7 - 085

119 Main Transf ormer

1

T7 - 119

86

Frame Side Cover - Left

1

T7 - 086

120 N/A

87

Frame Side Cover - Right

1

T7 - 087

121 N/A

88

Plastic Clamp - Top

2

T7 - 088

122 N/A

89

Plastic Clamp - Bottom

2

T7 - 089

123 Motor Control Board Cov er

1

T7 - 123

90

Bracket

2

T7 - 090

124 Motor Control Board Radiator

1

T7 - 124

91

M8 x 25mm Screw

4

T7 - 091

125 Rear Frame

1

T7 - 125

92

Rear Roller

1

T7 - 092

126 Foot Platf orm Support Frame

1

T7 - 126

93

Rear Roller Shaft

1

T7 - 093

127 Deck Frame Side Cover - Left #2

1

T7 - 127

94

M8 x 43mm Bolt

2

T7 - 094

128 Deck Frame Side Cover - Right #2

1

T7 - 128

95

M8 Ny lon Nut

12

T7 - 095

129 10 x 16 Washer

1

T7 - 129

96

Deck Wheel

2

T7 - 096

130 Side Rail Guide Light

2

T7 - 130

97 Rubber

Dot

1

SET

T7 - 097

98

Deck Wheel Bracket

2

T7 - 098

99

Elev ation Support Tube Side Cover

- Lef t

1

T7 - 099

100

Elev ation Support Tube Side

Cov er - Right

1

T7 - 100

101 Elev ation Support Tube

1

T7 - 101

102 Motor Belly Pan

1

T7 - 102

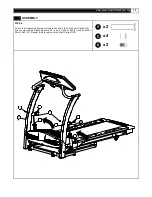

Summary of Contents for MOMENTUM T7

Page 1: ...MOMENTUM T7 TREADMILL USER MANUAL...

Page 24: ...24 MOMENTUM T7 TREADMILL...