EVO205D SAFE / SURE-Trak 6. MAINTENANCE

6-2

©GreenMech

Ltd

6-2

03/22

SMART SENSE Controller Settings

Refer to dealer or GreenMech Ltd.

ENGINE MAINTENANCE

REFER TO ENGINE MANUAL

TRACK MAINTENANCE

REFER TO TRACK MANUAL

Recommended lubricants

Specification

Hydraulic Oil

ISO 32

Grease

Complex grease EP2 (high temperature)

Engine

SAE 15W-40 APICD

6.1

Lubrication Points

Left to Right on remote manifold

– grease points 6.1.3 >> 6.1.10.

Grease except where stated - All models (except where stated)

6.1.1

Tracks

See Track Manual

6.1.2

Fixed Feed roller bearing

1 nipple behind spare wheel

Remote nipples on manifold in order from left to right

6.1.3

Chipper flywheel front bearing

1 nipple on remote manifold

6.1.4

Chipper flywheel rear bearing

1 nipple on remote manifold

6.1.5

Feed roller bearing

1 nipple on remote manifold

6.1.6

Feed roller pivot

1 nipple on remote manifold

6.1.7

Drive belt idler pulley

1 nipple on remote manifold

6.1.8

Drive shaft bearing

1 nipple on remote manifold

6.1.9

Upper Leg pad

1 nipple on remote manifold

6.1.10

Lower Leg pad

1 nipple on remote manifold

6.1.11

Feed Roller stop bar

Clean and grease pivots sparingly

Note 1: Do not over-grease bearings as damage to seals may occur.

40 hours requires only one full pump of hand operated cartridge gun.

Note 2: Use high temperature grease on chipper flywheel bearings.

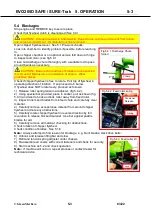

Fig 6.1 Lubrication points EVO205D SureTrak

Chipper flywheel cover

– 6.1.8

Engine cover

R H side cover (battery

– see 6.13)

From LH

6.1.3

6.1.4

6.1.5

6.1.6

6.1.7

6.1.8

6.1.9

6.1.10

6.1.2

6.1.1

6.1.11