Greentec HS172-212-242 Cutterbar

39

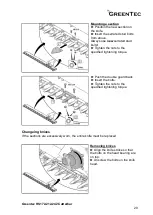

Dismantling the head bearing

►

Loosen the bolt on the knife

head.

►

Remove the head bearing

from the knife head. You can

spread the knife head

somewhat by inserting a small

screwdriver into the slot of the

knife head.

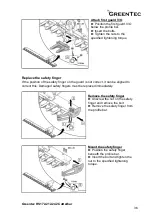

Installing the head bearing

►

Insert the head bearing in

the new knife head and align it

rougHSy. You can spread the

knife head somewhat by

inserting a small screwdriver

into the slot of the knife head.

►

Tighten the bolt hand-tight.

Mounting the knife head

►

Place the knife head on the

sections.

►

Tighten the bolts to the

specified tightening torque.