12

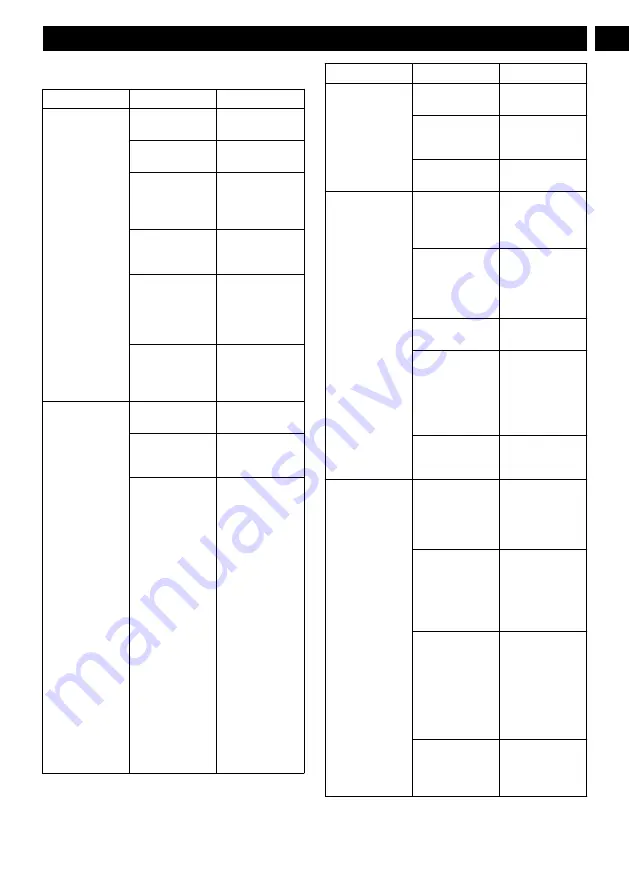

TROUBLESHOOTING

Problem

Possible cause

Solution

The guide bar and

the chain become

hot and release

smoke.

The chain is too

tight.

Adjust the chain

tension.

The oil tank is

empty.

Add lubricants.

Contamination

causes a blockage

of the discharge

port.

Remove the guide

bar and clean the

discharge port.

Contamination

causes a blockage

of the oil tank.

Clean the oil tank.

Add new lubri-

cant.

Contamination

causes a blockage

of the guide bar

and the oil tank

cap.

Clean the guide

bar and the oil

tank cap.

Contamination

causes a blockage

of the sprocket or

guide wheels.

Clean the sprocket

and the guide

wheels.

The motor runs

but the chain does

not rotate.

The chain is too

tight.

Adjust the chain

tension.

The guide bar and

the chain are dam-

aged.

Replace the guide

bar and the chain

if it is necessary.

The motor is dam-

aged.

1. Remove the

battery pack

from the ma-

chine.

2. Remove the

guide bar cov-

er.

3. Remove the

bar and saw

chain.

4. Clean the ma-

chine.

5. Install battery

pack and oper-

ate the ma-

chine.

If the sprocket ro-

tates, it means the

motor works prop-

erly. If not, call

service center.

Problem

Possible cause

Solution

The motor runs

and the chain ro-

tates, but the chain

does not cut.

The chain is blunt.

Sharpen or replace

the saw chain.

The chain is in the

incorrect direction.

Turn the chain

loop to the other

direction.

The chain is tight

or loose.

Adjust the chain

tension.

The machine does

not start.

The chain brake is

engaged.

Pull the chain

brake in the direc-

tion of the user to

disengage it.

The machine and

battery are not

connected correct-

ly.

Make sure that the

battery release

button clicks when

you install the bat-

tery pack.

The battery level

is low.

Charge the battery

pack.

The lock out but-

ton and the trigger

are not pushed at

the same time.

1. Push the lock-

out button and

hold it.

2. Push the trig-

ger to start the

machine.

The battery is too

hot or too cold.

Refer to battery

and charger man-

ual.

The motor runs,

but the chain does

not cut correctly,

or the motor stops

after around 3 sec-

onds.

The machine is in

the protection

mode to protect

the PCB.

Release the trigger

and start the ma-

chine again. Do

not force the ma-

chine to cut.

The battery is not

charged.

Charge the battery.

Refer to the bat-

tery and charger

manual for correct

charging proce-

dures.

The chain is not

lubricated.

Lubricate the

chain to decrease

the friction. Do

not let the guide

bar and the chain

operate without

sufficient lubri-

cant.

Incorrect battery

storage tempera-

ture

Cool the battery

pack until it de-

creases to the am-

bient temperature.

9

English

EN