10.3 SHARPEN THE CUTTERS

Sharpen the cutters if chain does not go into wood easily.

NOTE

We recommend that a service center, which has an electric

sharpener, perform important sharpening work.

1. Tensioning chain.

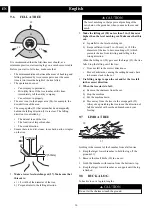

2. Sharpen the cutters corner with a 5/32 in. (4 mm)

diameter round file .

3. Sharpen the top plate, side plate and depth gauge with a

flat file.

4. File all the cutters to the specified angles and the same

length.

NOTE

During the process:

•

Keep the file flat with the surface to be sharpened.

•

Use the midpoint of the file bar.

•

Use light but firm pressure when sharpening the

surface.

•

Lift the file away on each return stroke.

•

Sharpen the cutters on one side and then move to the

other side.

Replace the chain if:

•

The length of the cutting edges is less than 1/5 in. (5

mm).

•

There is too much space between the drive links and the

rivets.

•

The cut speed is slow.

•

Sharpening the chain many times but it does not increase

the cutting speed. The chain is worn.

10.4 GUIDE BAR MAINTENANCE

NOTE

Make sure that the bar is turned over periodically to keep

symmetrical wear on the bar.

1. Lubricate the bearings on the nose sprocket (if present)

with the syringe (not included).

2. Clean the bar groove with the scraping hook (not

included).

3. Clean the lubrication holes.

4. Remove burr from the edges and level the cutters with a

flat file.

Replace the bar if:

13

English

EN