32

P0803466-00 v.2.0

MAINTENANCE

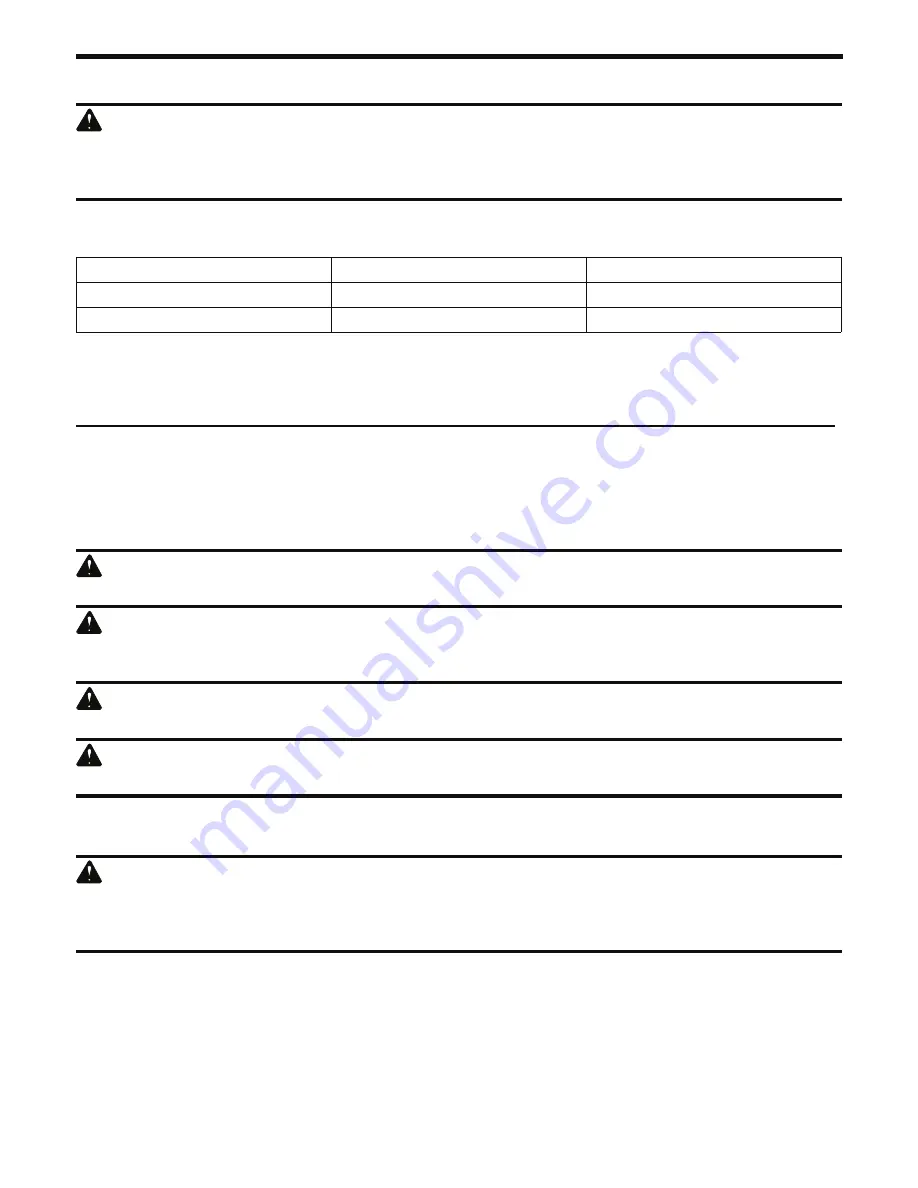

TORQUE VALUES

W A R N I N G

Particular attention must be given to tightening the drive wheel lug nuts and blade spindle bolts. Failure to

correctly torque these items may result in the loss of a wheel or blade, which can cause serious damage or

personal injury.

Torque values are given below:

Part

Ft-lbs.

Nm

Wheel (lug) nuts

126.5

120

Blade spindle bolt bottom

90.1

95

Lug nuts only

- It is recommended that these be checked after the first 2 hours of operation, initially,

every 100 hours and following removal for repair or replacement.

For all other torques refer to the various mower parts manuals for standard torque chart.

NOTE: The blade adapter will come off when the blade cap screw is removed. Touch-up sharpening can

be done with a file. Check the blades for balance following grinding. A balancing tool is available through

most hardware supply stores, or balancing can be done by placing the blade on an inverted line punch or

1/2" bolt. Blade should not lean or tilt. While spinning the blade slowly, it should not wobble. If blade is out

of balance, true it up before reinstalling. Lay the blade on a flat surface and check for distortion. Replace

any distorted blade.

W A R N I N G

The blade sail (curved part) must be pointing upward toward the inside of the deck to ensure proper cutting.

W A R N I N G

When mounting blades, rotate them after installation to ensure blade tips do not touch each other or sides

of the mower.

W A R N I N G

Failure to correctly torque the bolt may result in the loss of the blade, which can cause serious injury.

W A R N I N G

Mower blades are sharp and can cut. Wear gloves and use extra caution when servicing them.

CLEANING THE MOWER

W A R N I N G

In order to reduce the risk of electric shock, do not expose the mower to water. The underside of the

mower deck should be cleaned after each use because grass clippings, leaves, dirt, and other debris will

accumulate, which will cause rust and corrosion.

Remove any build-up of grass and leaves on or around the motor cover (do not use water). Occasionally

wipe the mower clean with a dry cloth. If debris builds up on the underside of the mower during use, stop

the motor, turn off the machine, and scrape it clean using an appropriate tool.

STORING THE MOWER

The following steps should be taken in order to prepare the lawn mower for storage.

• Clean the mower as described in the previous section.