Page 8

SKU 65075

For technical questions, please call 1-800-444-3353.

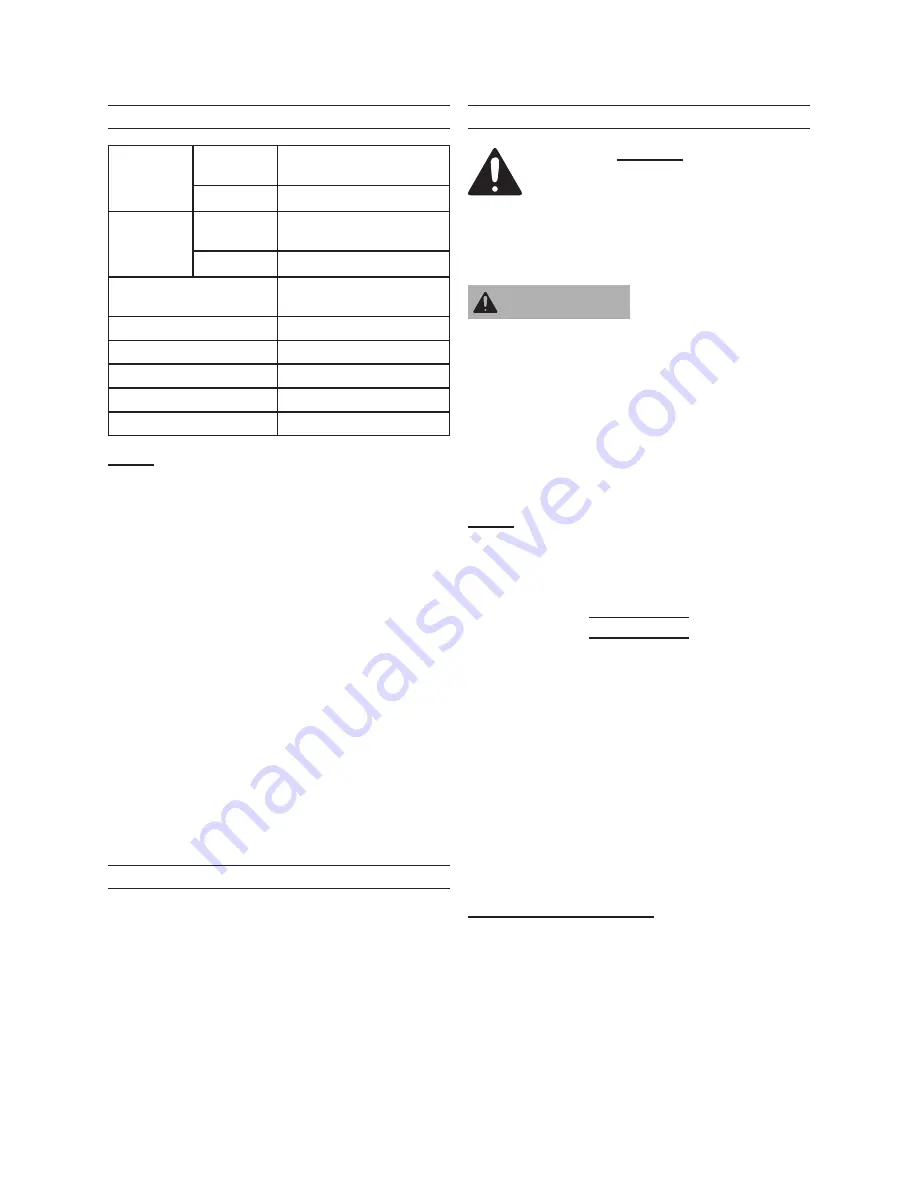

Basic speciFications

Fuel

Type

86+ octane unleaded

gasoline

Capacity

0.95 Gallons

Engine Oil

Type SAE: 10W 30 above 32° F

5W30 at 32° F or below

Capacity

0.63 Quarts

Hydraulic Fluid

Capacity

2.5 Gallons

Engine Speed

3,600 RPM

Engine Family

7CGPS.1961 GA : EM

Maximum Log Size

25” L x 8” Diameter

Maximum Pressure

2,800 PSI

Tire Air Pressure

60 PSI (cold)

note:

Additional specifications found in

the TECHNICAL ENGINE SPECIFI-

CATIONS chart in this manual.

The emission control system for this

engine is warranted for standards set by

the U.S. Environmental Protection Agency

and by the California Air Resources Board

(also known as CARB). For warranty

information, refer to the last pages of this

manual.

At high altitudes, the engine’s carbu-

retor, governor (if so equipped), and any

other parts that control the fuel-air ratio will

need to be adjusted by a qualified me

-

chanic to allow efficient high-altitude use

and to prevent damage to the engine and

any other devices used with this product.

unpacking

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please

call Harbor Freight Tools at the number

shown on the cover of this manual as soon

as possible.

set up instructions

read the entire iMportant

saFety inForMation

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

risk of accidental

starting; resulting

in serious personal injury.

turn the power switch of the

equipment to its “oFF”

position, wait for the engine to

cool, and unplug the spark

plug wire(s) before

assembling or making any

adjustments to the equipment.

note:

For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

assembly

This equipment has a spark arresting

1.

muffler included. A spark arresting

muffler is required by law in Califor

-

nia, on some US Forest Service land,

and possibly in other areas or situa-

tions.

Due to the size of the Log Splitter and

2.

its components, assistance may be

required during the entire assembly

process.

packing the bearings.

Using a suitable solvent, clean the

3.

bearings and the rest of the parts in

the Hub assembly. The parts must be

cleaned even if they are new or ap-

pear clean.

Allow all pieces to dry completely.

4.

Warning