Page 20

PSL 5.0 Pump Station Level Controller

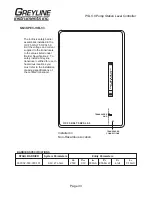

SENSOR MOUNTING METHODS

4"

OR

6"

BL

I

ND FLANGE

TAPPED

¾"

NPT

FLEX

I

BLE

CONDU

I

T

J

UNCT

I

ON

BOX

(OPT

I

ON

J

B)

I

SOLAT

I

ON

COUPL

I

NG

(SUPPL

I

ED)

MUST BE

USED

DO NOT

CLAMP

I

N

T

HI

S AREA

¾"

NPT

N

I

PPLE

F

LANGE

M

OUNT

I

SOLAT

I

ON

COUPL

I

NG

(SUPPL

I

ED)

MUST BE

USED

DO NOT

CLAMP

I

N

T

HI

S AREA

CLAMP

3

/4"

CONDU

I

T

CROSS BAR

M

OUNT

I

SOLAT

I

ON

COUPL

I

NG

(SUPPL

I

ED)

MUST BE

USED

DO NOT

CLAMP

I

N

T

HI

S AREA

3

/4"

NPT

N

I

PPLE

ANGLE

M

OUNT

I

SOLAT

I

ON

COUPL

I

NG

(SUPPL

I

ED)

MUST BE

USED

DO NOT

CLAMP

I

N

T

HI

S AREA

3

/4"

CONDU

I

T

CONDU

I

T

M

OUNT

Notes

:

1

.

Use the

¾"

NPT

"I

so

l

ation

Coup

l

ing

"

supp

l

ied and

on

ly.

Do not c

l

amp sensor

b

od

y

or stem

.

2

.

Locate the sensor 1 ft (30 cm) from

the sidewa

ll

or o

b

struction for e

v

er

y

10 ft (3 m) depth

.

3

.

mount in direct sun

l

ight

.

4.

E

x

tend sensor ca

bl

e up to

5

00 ft

(1

5

0 m) with RG

6

2AU coa

x

ia

l

on

ly.

hand

tighten

Do not

GR

I

ND OR F

I

LE

P

I

PE EDGE

SMOOT

H

STAND P

I

PE

M

OUNT

STANDP

I

PE LENGT

H

AS S

H

ORT AS POSS

I

BLE

STANDP

I

PE D

I

AMETER

AS LARGE AS POSS

I

BLE

TYP

I

CAL STANDP

I

PE

:

4” /

100 mm D

I

AMETER

12

” /

300 mm LENGT

H

NARROW D

I

AMETER

STANDP

I

PES (

<4” /

100 mm)

MAY AFFECT ACCURACY

OF READ

I

NG