Page 1

INTRODUCTION

The room CO

2

transmitter device uses a highly accurate and reliable non-

dispersive infrared (NDIR) sensor in an attractive, low profile enclosure for

room applications to monitor CO

2

levels. The sensor uses dual channel optics

and LTA (long term adjustment) signal processing technology to deliver

industry leading long-term accuracy and reliability. These technology

features ensure optimum measurement stability for both periodic and

constant occupancy applications, so the device is equally suitable for the

classroom or the hospital room.

Standard features include a field selectable output signal of either 4-20

mA, 0-5 Vdc or 0-10 Vdc for the highest versatility, programmable CO

2

measurement span, a backlit alpha-numeric LCD and easy menu operation

for configuration.

Optional features include a resistive temperature sensor output (with LCD display of temperature in either

°C or °F), a control relay with programmable setpoint, hysteresis and time delay, an up/down setpoint

control with various resistive output ranges and a dry-contact override switch.

BEFORE INSTALLATION

Read these instructions carefully before installing and commissioning the device. Failure to follow these

instructions may result in product damage. Do not use in an explosive or hazardous environment, with

combustible or flammable gases, as a safety or emergency stop device or in any other application where

failure of the product could result in personal injury. Take electrostatic discharge precautions during

installation. De-energize the power supply prior to installation, this device is intended for indoor air

conditioned spaces, contact factory or other applications.

Do not exceed device ratings. This product is

not intended for life-safety applications.

NOTE:

This CO

2

sensor incorporates a Self Calibration feature to

correct CO

2

sensor drift. This feature is recommended for applications

where the CO

2

will be exposed to fresh air (400 ppm) at least one hour

per day. If the monitored space is occupied 24 hours or consistently

maintains higher or lower levels of CO

2

, it is recommended that this

feature be turned off, but yearly calibration will be required. If the self

calibration is disabled at installation time without allowing for 7 day

auto calibration cycle, then a manual calibration should be performed

to ensure accuracy of the device.

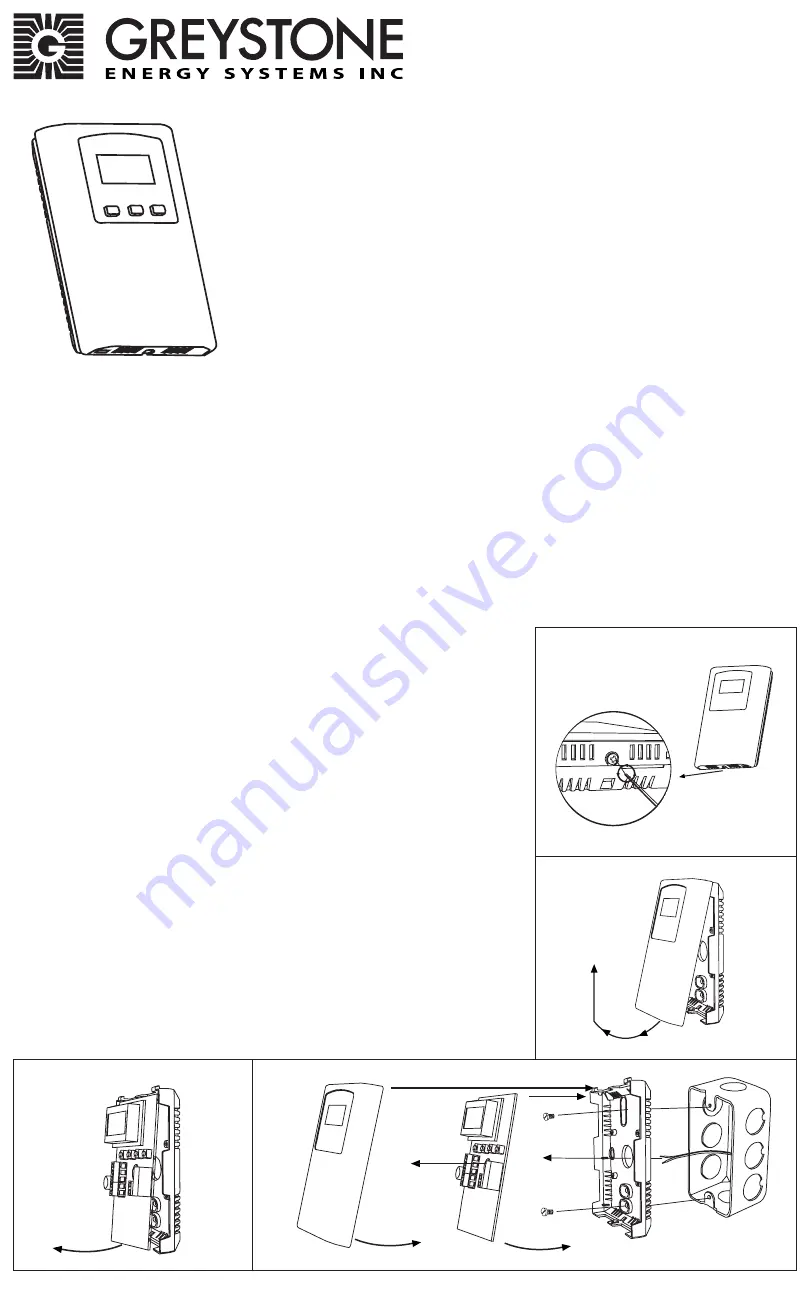

MOUNTING

The transmitter installs directly on a standard electrical box and

should be mounted five feet from the floor of the area to be

controlled. Do not mount the sensor near doors, opening windows,

supply air diffusers or other known disturbances. Avoid areas where

the detector is exposed to vibrations or rapid temperature changes.

Prevent measurement errors by sealing the wall or conduit openings

to prevent air migration from the wall cavity.

The cover is hooked to the base at the top edge and must be removed

from the bottom edge first. Use a small Phillips screwdriver to loosen

the security screw as shown in Figure 1. Complete removal of the

screw is not required. Use the screwdriver to carefully pry each bottom

corner if necessary. Tip the cover away from the base and sit it aside as

shown in Figure 2.

Figure 1

Figure 2

Figure 4

Figure 3

Cover

PCB

Backplate

IN-GE-CD2RMCXXX-04

Copyright © Greystone Energy Systems, Inc. All Rights Reserved Phone: +1 506 853 3057 Web: www.greystoneenergy.com

Room Carbon Dioxide Transmitter

CD2RMC Series - Installation Instructions