Page 3

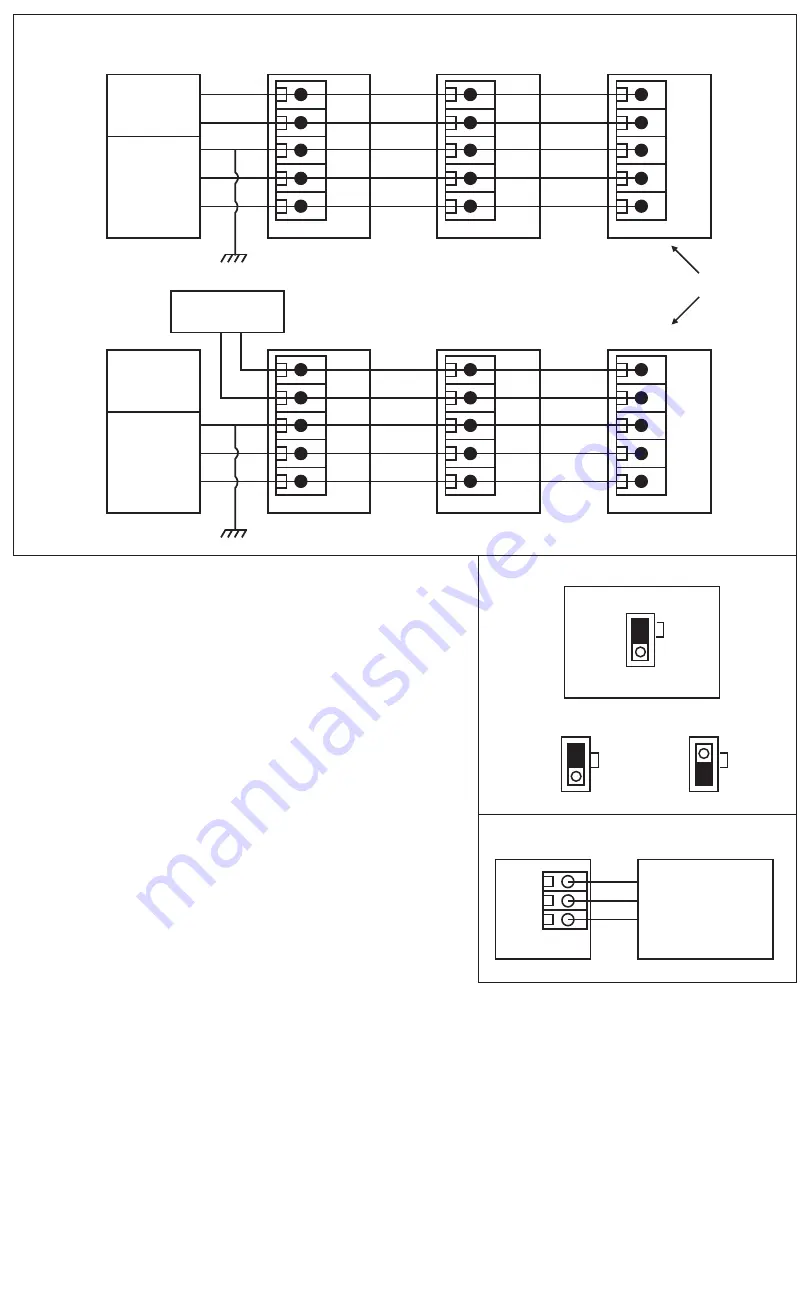

If the device includes the optional network connection, use

twisted shielded pair to connect to the terminals marked

A-, B+ and SHLD (SHIELD). The positive wire connects to B+,

the negative to A- and the cable shield must be connected

to the SHLD terminal on each device. The shield wire should

be connected to earth ground at one end of the network

only. See Figure 7. If the device is installed at either end of

an RS-485 network, an end-of-line (EOL) termination resistor

(121 ohms) should be installed in parallel with the A- and B+

terminals. This device includes a network termination resistor

and jumper that can be used to connect the EOL resistor on

the PCB. Simply move the jumper to the EOL position and no

external resistor is required. See Figure 8.

A network segment is a single shielded wire loop run between

several devices (nodes) in a daisy chain configuration. The

total segment length should be less than 1220 meters (4000

feet) and the maximum number of nodes on one segment

length is 64. Nodes are any device connected to the loop and

include controllers but do not include the EOL terminators.

To install more than 64 devices, or to increase network

length, repeaters will be required for proper communication.

The maximum daisy chain length (segment) depends on transmission speed (baud rate), wire size and

number of nodes. If communication is slow or unreliable, it may be necessary to wire two daisy chains to

the controller with a repeater for each segment.

An optional signal is the alarm relay output available on the NO (NORMALLY OPEN), NC (NORMALLY

CLOSED ) and R.COM (RELAY COMMON) terminals. The R.COM terminal is not connected to the power

supply COM terminal, the relay output is completely isolated. The relay contacts may be connected to a

controller Digital Input (DI) for status monitoring or used to directly control an alarm or ventilation fan. Do

not exceed the device contact ratings. In some cases a separate control relay may be used between the

particulate matter sensor relay and a large fan for example. See Figure 9.

Figure 7

Set EOL Jumper

Building Controller

Device 01

Device 02

Device 03

Connect Shield One End Only

PWR

COM

PWR

COM

PWR

COM

SHLD

B+

A-

SHLD

B+

A-

SHLD

B+

A-

BACnet® Master

24 Vac / dc

Common

Shield

B+

A-

Building Controller

Device 01

Device 02

Device 03

Connect Shield One End Only

PWR

COM

PWR

COM

PWR

COM

SHLD

B+

A-

SHLD

B+

A-

SHLD

B+

A-

BACnet® Master

24 Vac / dc

Common

Shield

B+

A-

External 24 Vdc Power

Supply or 24 Vac

Transformer

Figure 8

Figure 9

EOL

EOL

EOL

OFF

ON

Digital Input

Digital Input

Digital Input

NO

R. COM

NC

Controller

IN-GE-PMRMCXXX-05

Copyright © Greystone Energy Systems, Inc. All Rights Reserved Phone: +1 506 853 3057 Web: www.greystoneenergy.com