Page 1

INTRODUCTION

The CO Transmitter uses an electrochemical

sensor to monitor the carbon monoxide level

and outputs a field-selectable 4-20 mA or

voltage signal. The voltage signal may also be set

to 0-5 or 0-10 Vdc. The sensing range and output

may be scaled to either 100, 150, 300, 400 or 500

ppm via the on-board menu. A front panel LCD

is standard to ensure easy setup and operation.

Other standard features include a back light

for the LCD, a front panel test switch, status

indication and an alarm buzzer. The test function

may also be controlled remotely with a digital

input signal. A three-key menu is implemented to allow local configuration of all device parameters.

BEFORE INSTALLATION

Read these instructions carefully before installing and commissioning the CO Transmitter. Failure to follow

these instructions may result in product damage. Do not use in an explosive or hazardous environment,

with combustible or flammable gases, as a safety or emergency stop device or in any other application

where failure of the product could result in personal injury.

Take electrostatic discharge precautions

during installation and do not exceed the device ratings.

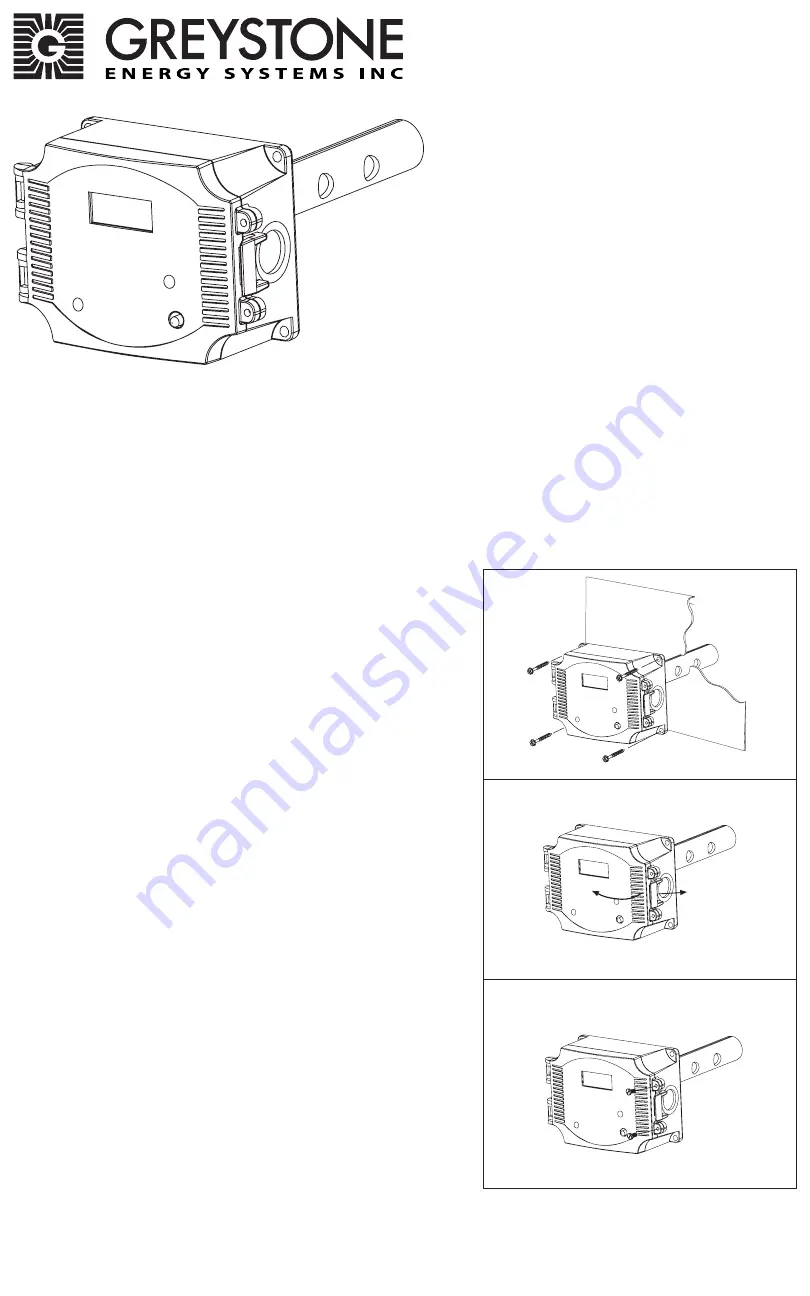

MOUNTING

The CO duct type sensor installs on the outside of a return

air duct with the sampling tube inserted into the duct. Use

the included foam plug to prevent air from entering the

enclosure through the conduit and causing an incorrect

reading. Mount the sensor in an easily accessible location

in a straight section of duct at least five feet from corners

and other items that may cause disturbances in the air flow.

Avoid areas with vibrations or rapid temperature changes.

The duct CO detector principal of operation is based on the

Venturi effect of the probe that extends into the HVAC duct.

Air flowing through the duct is forced into the vent holes on

one side of the probe, into the enclosure, over the CO sensor

and then is drawn back out of the enclosure via the probe

vent holes on the opposite side.

Drill or punch a 1-1/8” or 1-1/4” hole in the duct at the

preferred location and insert the probe into the hole to mark

the enclosure mounting holes. Remove the unit and drill the

four mounting holes. Clean all drilled holes of debris before

mounting the device. Mount the enclosure to the duct with

four sheet metal screws such that the duct air flow is parallel

with the vent holes in the probe (i.e.: air flows directly into

the probe holes). To prevent air leaks, ensure the gasket is

compressed around the probe between the device enclosure

and the air duct.

Open the cover by releasing the latch and connect the device

according to the wiring instructions. After wiring and setup

are complete, close and latch the cover. Secure it with two

self-tapping screws in the holes provided.

HARDWARE SETUP

The only hardware setup required is to select the analog

output type with the PCB switch labeled VOLT and mA. Slide

the switch to the correct position for the required output

signal type, either 4-20 mA or 0-5/10 Vdc.

Figure 1

Figure 3

Figure 2

IN-GE-CMD5B5XXX-01-02 03/19

Copyright © Greystone Energy Systems, Inc. All Rights Reserved Phone: +1 506 853 3057 Web: www.greystoneenergy.com

Carbon Monoxide Transmitter

CMD5B5 Series - Installation Instructions