Page 2

POWER AND ANALOG OUTPUT WIRING

Use 22 AWG shielded wire for all connections and do not locate the device wires in the same conduit with

wiring used to supply inductive loads such as motors. Disconnect the power supply before making any

connections to prevent electrical shock or equipment damage. Make all connections in accordance with

national and local codes.

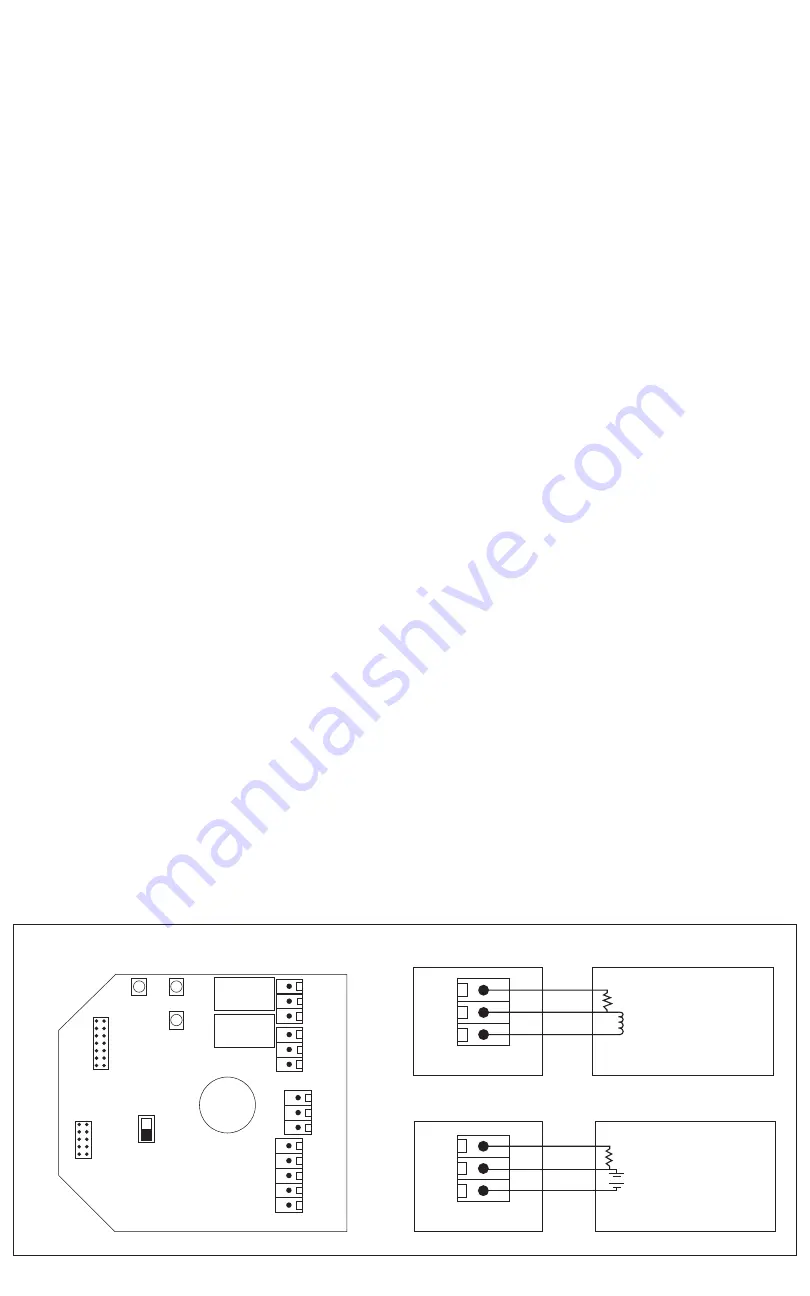

The wiring configuration depends on the specific model and the installed options. Follow the example

wiring diagrams to determine the correct wiring. All models have the same terminal functions. This device

has a half-wave type power supply so the power supply common is the same as the output signal common.

Therefore, several devices may be connected to one power supply and the output signals all share the

same signal common. Use caution when grounding the secondary of an AC transformer or when wiring

multiple devices so that the circuit ground point is the same on all devices and the controller.

This is a 3-wire sourcing device. All models require a 24 Vac/dc power supply to operate. Connect the

positive dc voltage or the hot side of the ac voltage to the ANALOG - PWR terminal and the power supply

common to the ANALOG - COM terminal. Note that the Analog COM terminal is NOT connected to the

Relay COM terminals. The device is reverse voltage protected and will not operate if the power supply is

connected backwards.

The linear output signal (either 4-20 mA or 0-5/10 Vdc) is available on the ANALOG - CO terminal. The

signal is referenced to the Analog COM terminal. The 4-20 mA output signal operates in the Active mode

and does not require a loop power supply. This means the signal current is generated by the transmitter

and must not be connected to a powered input or device damage will result. This is the typical operating

mode of a “three-wire device”. Ensure the controller Analog Input (AI) matches the CO Transmitter output

signal type before power is applied. The current signal has a maximum load that it will drive and the

voltage output has a minimum load. Follow the ratings in the Specification section or inaccurate readings

may result. The power must be disconnected to change from VOLT to mA. The analog output CO signal is

typically connected directly to the Building Automation System (BAS) and used as a control parameter or

for logging purposes.

REMOTE TEST WIRING

The CO Transmitter has a Test function that will test the analog output and the alarm relays which is initiated

by pressing the front panel TEST switch. The Test function may also be initiated remotely by shorting the

TEST + and TEST - terminals. Note that the TEST - terminal is connected to the Analog COM terminal. The

TEST terminals should only be connected to a dry-contact digital output from the controller that is either

shorted or floating open. Ensure no power is applied to the TEST terminals. The TEST terminals may also be

connected to a remote switch. If desired, only one wire need be connected to the TEST + terminal and use

the power supply COM as the return signal path.

ALARM RELAY WIRING

If equipped, the alarm relay outputs are available on the NO, COM and NC terminals for each relay. The

relay COM terminals are NOT connected to the signal or power supply COM terminal nor to each other. The

two relays are completely isolated and have both Normally Open (NO) and Normally Closed (NC) contacts.

These signals can be used to directly control alarms, ventilation fans or may be connected to digital inputs

of the BAS for status monitoring. Ensure any loads connected to the relays are within the relay ratings in

the Specification section.

Figure 4

Analog Input for

4-20 mA CO Signal

24 Vac Power

Controller

CO

COM

PWR

250R

Com

Hot

Analog Input for

0-5 Vdc CO Signal

24 Vdc Power

Controller

CO

COM

PWR

1M

Com

+

Wiring for 4-20 mA Output Signal

Wiring for 0-5 Vdc Output Signal

RELA

Y 1

NC

COM

NO

RELA

Y 2

COMM

LCD

ROLL

MENU

POWER

PCB

VOLT

mA

+

TEST

-

CO

COM

PWR

A-

B+

SHLD

NC

COM

NO

IN-GE-CMD5B5XXX-01-02 03/19

Copyright © Greystone Energy Systems, Inc. All Rights Reserved Phone: +1 506 853 3057 Web: www.greystoneenergy.com