the supplemental tube matches the number as deter-

mined in step 2. Secure with the #8 self-tapping screw

into the bottom of the permanent tube.

NOTE: For ducts greater than 1

1

/

2

feet in width, refer to sec-

tions [5.4.1] and [5.4.2].

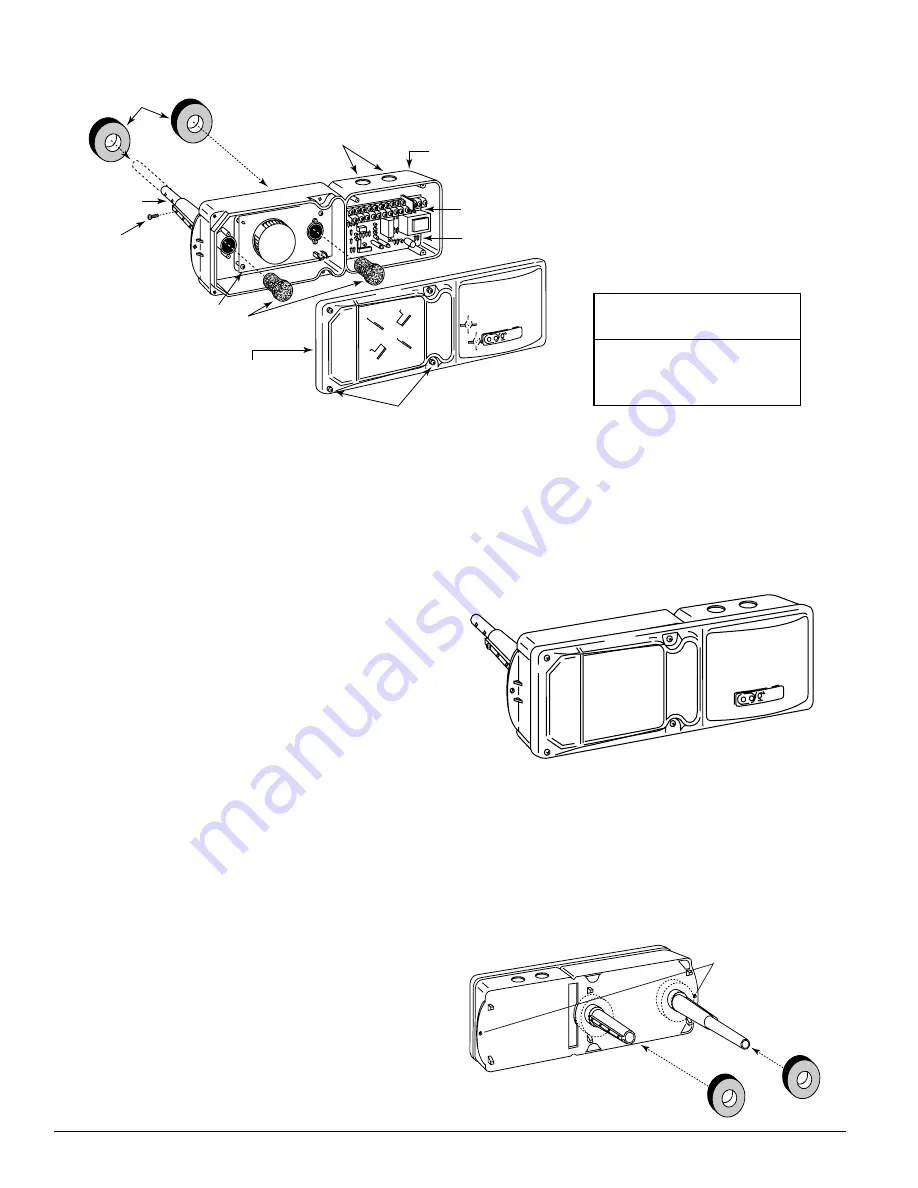

Figure 2. Sampling tube connected to duct smoke

detector:

[5.3] Secure The Detector Housing To The Duct

Slide the foam gaskets over the tube bushings as shown in

Figure 3. Use the two machine screws to screw the detector

housing to the duct. CAUTION: Do not overtighten the

screws.

Figure 3. Installation of foam gaskets over sampling

tube bushings:

SCREW HOLES FOR

ATTACHING HOUSING

TO DUCT WORK.

9. One inlet tube end plug

10. One telescoping sampling tube

11. One #8 self-tapping screw for the telescoping sampling

tube

NOTE: For ducts over 1

1

/

2

feet, longer inlet sampling tubes

must be ordered to complete the installation. They

must be the correct length for the width of the duct

where they will be installed. See Table 1 on page 3

to determine the inlet tube required for different duct

widths.

[5] Installation Sequence

[5.1] Verify Duct Air Flow Direction And Velocity

Model DH100ACDCA detectors are designed to be used in

air handling systems having air velocities of 500 to 4000 feet

per minute. Be sure to check engineering specifications to

ensure that the air velocity in the duct falls within these pa-

rameters. If necessary, use a velocity meter to check the air

velocity in the duct.

[5.2] Drill The Mounting Holes

Remove the paper backing from the mounting template sup-

plied. Affix the template to the duct at the desired mounting

location. Make sure the template lies flat and smooth on the

duct. Center punch holes A and B. Drill the holes as indicat-

ed on the template. Insert the two jack nut receptacles.

Drive a #10 machine screw into jacket to flare the retainer,

then back out the screw to use for detector mounting.

[5.2.1] Sampling Tube Installation for Ducts Less

Than 1

1

/

2

Feet Wide (see Figure 2)

1. Remove the front cover.

2. Use the tube installation chart above to determine the set

screw setting.

3. Slide the sampling tube into the housing bushing.

4. Align the holes in the bushing with the holes in the sam-

pling tube. Make sure the number of exposed holes on

D100-68-00

2

I56-1525-000

FOAM

GASKETS

PLASTIC

SAMPLING TUBE

CONDUIT HOLES

DETECTOR

HOUSING

TERMINAL STRIP

DETECTOR

COVER

SAMPLING TUBE

FILTERS

COVER MOUNTING

SCREWS

PLASTIC SAMPLING TUBE

SELF-TAPPING SCREW

POWER BOARD

DETECTOR BOARD

Tube Installation Chart:

Supplemental

Duct

Tube Holes

W i d t h

5

12”-14”

6

14”-16”

7

16”-18”

[3] Figure 1: Exploded View Of Duct Smoke Detector Components