Wiring

• Deactivate the 24 Vac/dc power supply until all connections are made to the device to prevent electrical shock or

equipment damage.

• Use 14-22 AWG shielded wiring for all connections and do not locate the device wires in the same conduit with

wiring used to supply inductive loads such as motors. Make all connections in accordance with national and local

codes.

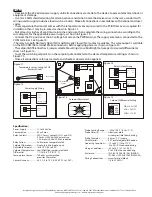

• The temperature thermostat comes with the temperature sensor pre-wired to the PCB. If removal is required for

installation then it may be re-wired as shown in Figure 11.

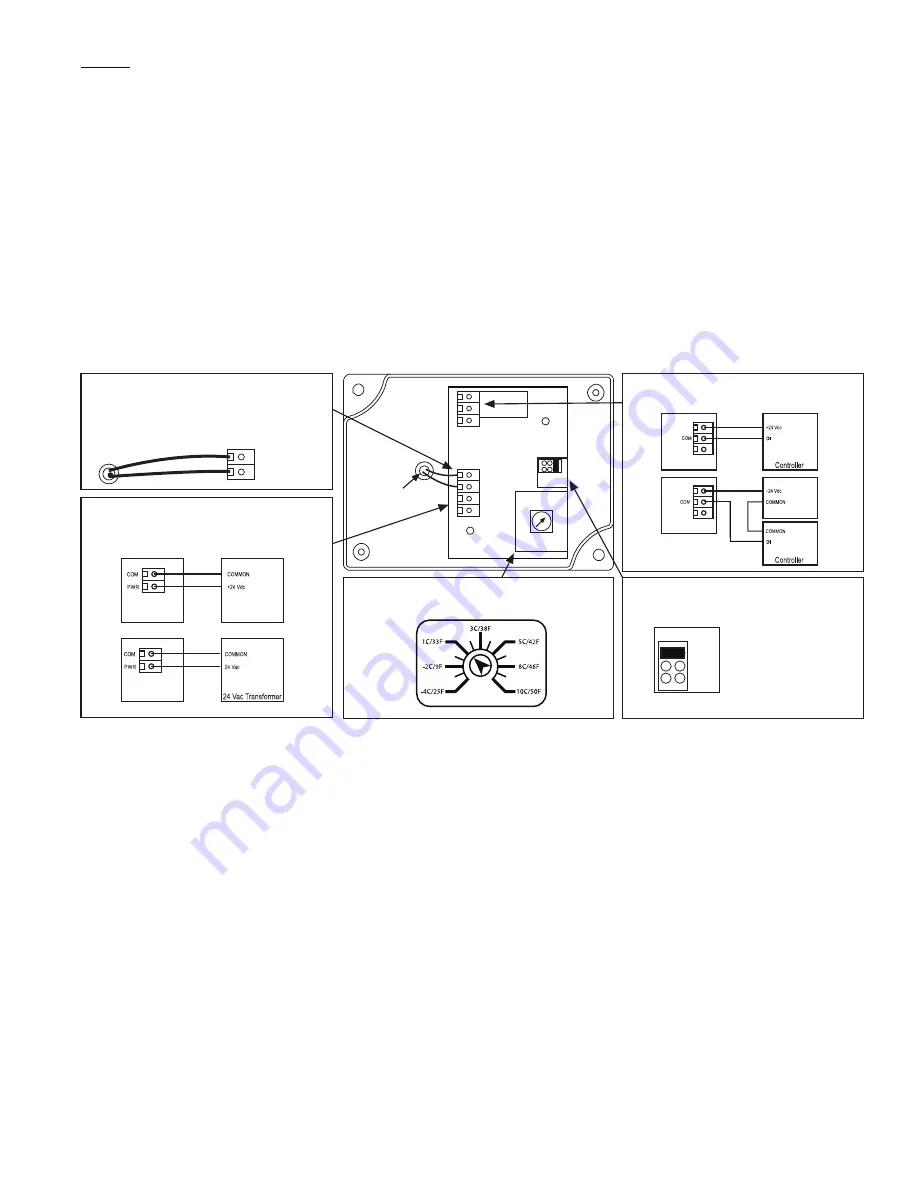

• Pull at least six inches of control wire into the enclosure, then complete the wiring connection according to the

wire diagram for the applicable power supply as shown in Figure 12.

• Connect the DC positive or the AC voltage hot side to the PWR terminal. The supply common is connected to the

COM terminal. See Figure 12.

•The relay has both Normally Open (NO) and Normally Closed (NC) contacts available. The relay output is available

on the NO/COM/NC terminal. Make connections before applying power as shown in Figure 13.

• The setpoint differential has 3 jumper selectable settings (Low/Mid/High) Set jumper to desired differential as

shown in Figure 14.

• To set the switching setpoint, turn the setpoint potentiometer to the desired temperature setting as shown in

Figure 15.

• Once all connections settings are made and checked, power can be applied.

Greystone Energy Systems, Inc. 150 English Drive, Moncton, NB E1E 4G7 Canada Tel: +1-506-853-3057 Tollfree (North America): +1-800-561-5611 Fax: +1-506-853-6014

Email: support@greystoneenergy.com Web: www.greystoneenergy.com

Temperature

Sensor

DIFFERENTIAL

HIGH

LOW MID

TEMP

PWR

COM

NC

NO

COM

SETPOINT

Temperature sensor wiring to PCB

(Factory Wired)

Figure 11

No Polarity

TEMP

Figure 12

24 Vdc Power Supply

Power Supply Wiring

DIFFERENTIAL

HIGH

LOW

MID

HIGH - 5.6C/10F

MID = 2.8C/5F

LOW = 1.1C/2F

Figure 14

Figure 15

Setpoint Adjustment

Setpoint Differential Setting

Specification:

Power Supply.......................12 to 28 Vac/dc

Consumption.......................50 mA max

Relay Contacts.....................SPDT, Form C contacts (N.O. and N.C.)

5 Amps @ 30 Vdc/250 Vac resistive

1.5 Amps @ 30 Vdc/250 Vac inductive

Relay Action..........................Activates on temperature fall

Setpoint Operation............Single-turn knob-pot on pcb

Adjustable Setpoint...........-4 to 10˚C (25 to 50˚F)

Setpoint Temperature ......Low/Mid/High jumper selectable

Differential 1.1/2.8/5.6 °C (2/5/10 ˚F)

Temperature Sensor..........10K ohm curve matched

precision thermistor

Sensor Accuracy..................±0.2˚C, 0 to 70˚C (±0.36˚F, 32 to 158˚F)

Probe Sensing Range ........-20 to 105 ˚C (-4 to 221 ˚F)

Probe Material ................ ....Aluminum plate

w/ compressible foam backing

Probe Diameter......... ..........38 mm (1.5”) square

Wire Material........................PVC insulated, parallel bonded

Operating Conditions.......-10 to 50˚C (14 to 122˚F),

5 to 95% RH non-condensing

Storage Conditions............-30 to 70˚C (-22 to 158˚F),

5 to 95%RH, non-condensing

Enclosure...............................(A) ABS, UL94-5VB, IP61 (NEMA 2)

(D)-ABS, UL94-5VB, IP65 (NEMA 4X)

Wiring Connections...........Screw terminal block

(14 to 22 AWG)

24 Vdc Power Supply

NO

NC

Digital

Input

NO

NC

Figure 13

Relay Output Wiring