10

STEP 10

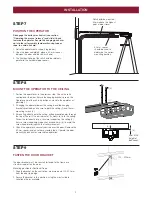

ATTACH DOOR ARM TO TROLLEY

Make sure the door is fully closed. Pull the manual release cord to

disengage the trolley. Slide the trolley to around 300mm from the

header bracket.

1. The Door Arm is already preassembled to the trolley.

2. Install the J-Bar onto the door bracket using the Clevis pin (1) and

R-Clip (2) supplied.

3. Move the Door Arm and J-Bars together and secure using two

bolts and nuts provided (3).

4. Ensure the angle of the Door Arm is around 20° from vertical,

when the door is fully closed.

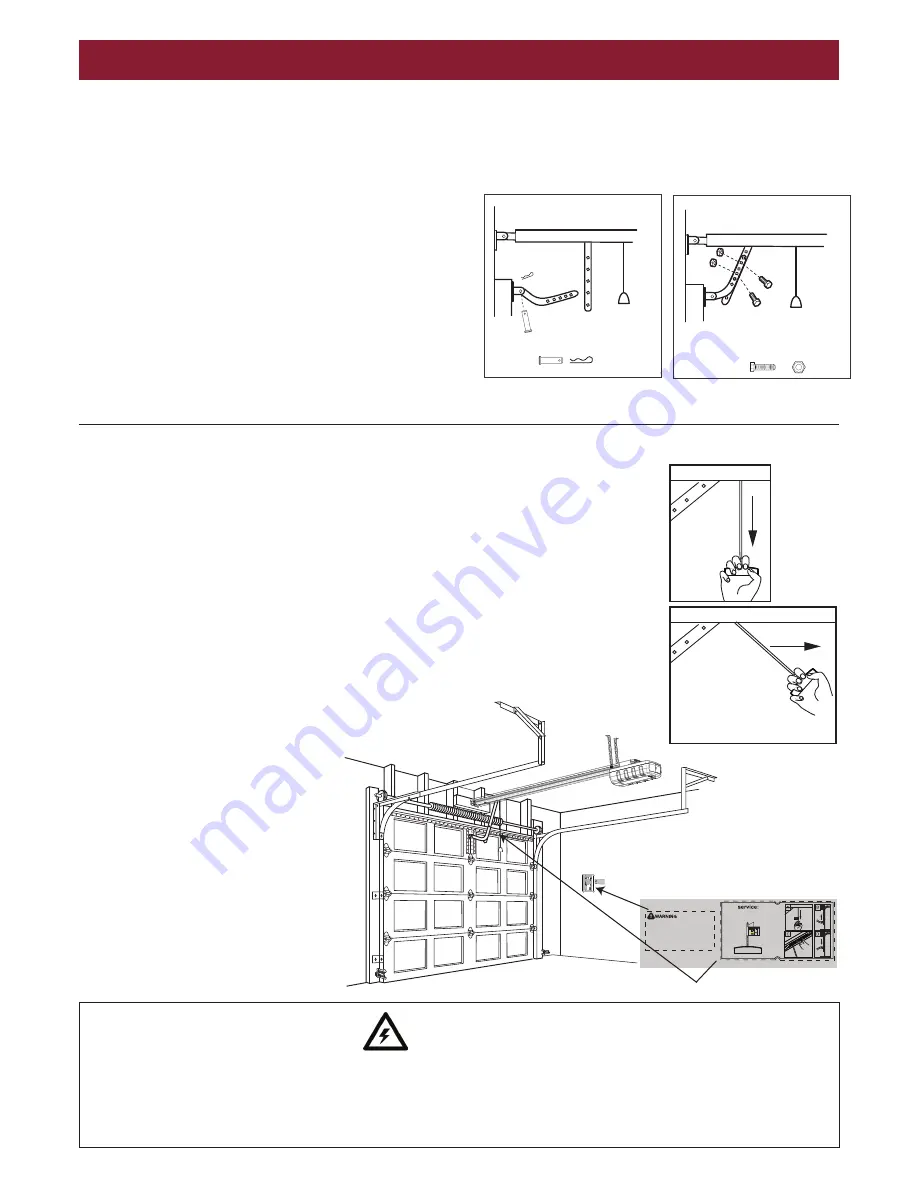

STEP 11

TESTING AND OPERATING THE MANUAL RELEASE

DO NOT DISENGAGE THE OPERATOR WITH CHILDREN, PERSONS OR OTHER OBJECTS

INCLUDING MOTOR VEHICLES WITHIN THE DOORWAY.

(The door is under significant tension and if the door has developed a fault or incorrect tension, it

may be unsafe and may fall rapidly.)

The manual release mechanism enables the door to be manually operated during power outages

or in an emergency.

The RED Manual Release cord is preassembled to the trolley. When the operator is installed the

handle should be no higher then 1.8 metres from the floor. The cord may need to be extended.

Attach the manual release Instruction Label around the cord as shown below.

DO NOT USE THE RED HANDLE TO OPEN AND CLOSE THE DOOR.

To operate the Manual Release. The door

should be fully closed if possible.

1. Disengage: Pull the manual release rope

and handle down to disconnect. This will

disengage the trolley, allowing the door to

be moved by hand, UP and DOWN as

many times as needed.

2. Re-engage: Pull the manual release rope

towards the motor until it springs back to its

original horizontal position. This will

re-engage the trolley, and when the door

passes the trolley position it will

automatically re-engage the operator.

INSTALLATION

WARNING

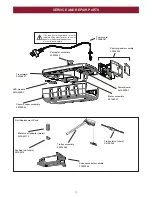

Connect Electric Power

TO AVOID INSTALLATION DIFFICULTIES, DO NOT RUN THE DOOR OPERATOR UNTIL INSTRUCTED TO DO SO

Connect to properly fused and earthed power outlet.

- Ensure all ropes and installation tools have been removed from the door

- When the operator is switched ON, the operator light flashes a number of times and then remains ON.

(1)

(2)

(3)

1

RISK OF ENTRAPMENT

Repeat Safety Reverse Test monthly. Door

must reverse on contact with a 40mm obstacle

placed on the floor. Make necessary adjustments.

AUTOMATIC DRIVE:

Keep away from the area of the door since it may

operate unexpectedly.

EMERGENCY RELEASE:

To release, pull down firmly on the red handle.

www.grifco.com.au

www.grifco.co.nz