7

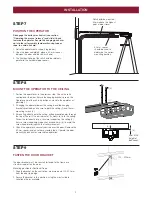

STEP 2

TIGHTEN THE CHAIN

STEP 3

FASTEN RAIL TO OPERATOR

36 - 38mm

(1)

(3)

(4)

(2)

M8 Screws

Note: The spring must be able to compress and bounce during

operation. Final tensioning can be performed after installation if

necessary. Over tightening the chain may overload the system and

cause excessive wear.

1. Tension the chain by adjusting the nut (1), on the pulley assembly,

clockwise until the spring is engaged.

2. Continue tightening to compress the spring and remove all the

slack in the chain. DO NOT OVERTIGHTEN but ensure chain is firm.

3. Adjust the spring to 36-38 mm as indicated in the diagram.

1. If using the hanging brackets to mount to ceiling, slide 1 x

M8 hex head screw into either side of the rail (1). Slide

screws 300mm from end of rail.

2. Position the rail drive sprocket (inside the rail) over the

operator motor shaft (2) and push down to install. Ensure

motor shaft adaptor (3) is in place.

3. Secure the rail on the operator with the Operator Mounting

Bracket (4) using ST6,3 x 18 mm screws.

This completes the assembly of the door operator to the rail.

STEP 1

CONNECT RAIL TO OPERATOR

Your door operator and rail are packed in two separate cartons. Remove the operator, rail and all the hardware in preparation for

assembly. The chain is pretensioned from the factory, however, it is advisable to check the tension and adjust if necessary as outlined in

step 2.

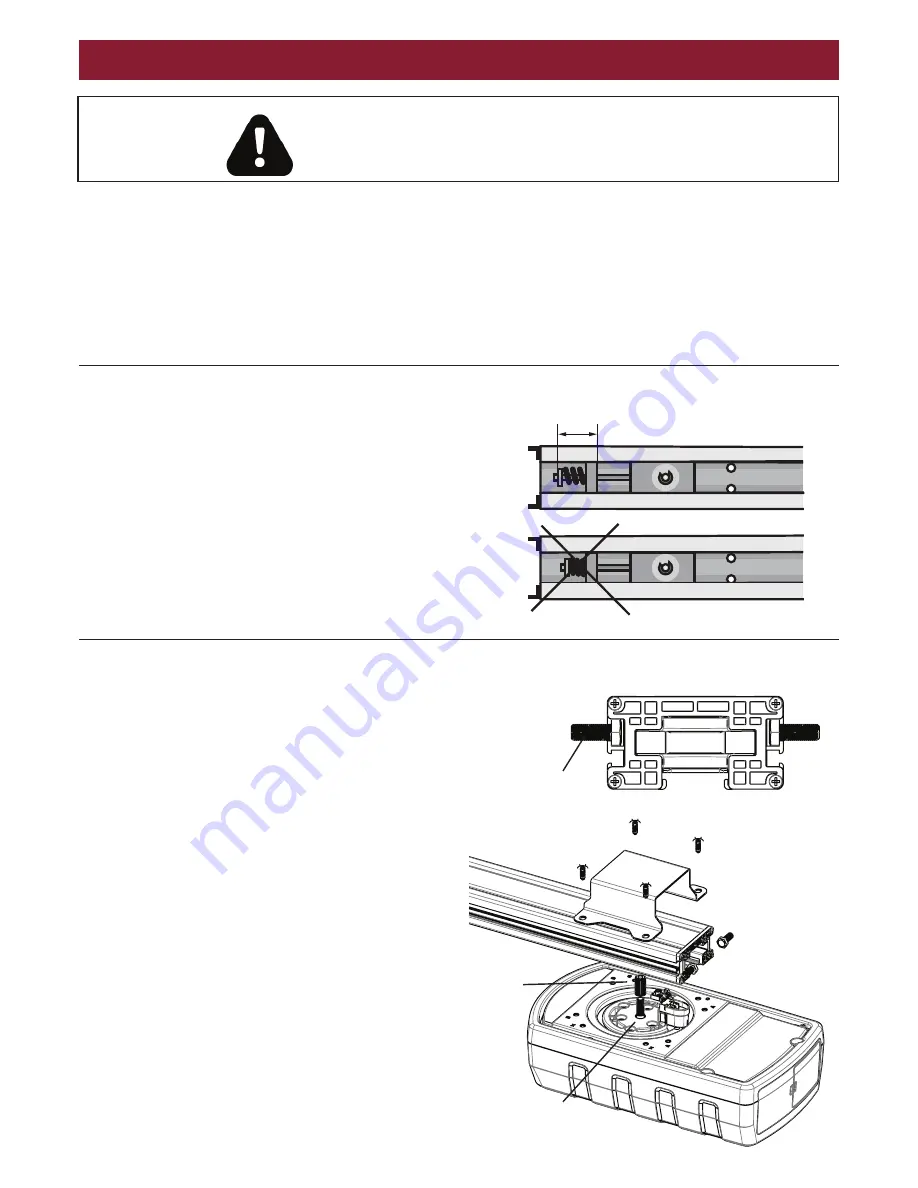

INSTALLATION

WARNING

Before beginning installation of the operator

check the door is in good mechanical condition,

opens and closes properly and correctly balanced