15

INSTALLATION CONTINUED

ALIGNMENT

The photoelectric sensor and reflector must be on the same horizontal plane to each other. When properly wired and aligned, the yellow

LED within the photoelectric sensor

WILL NOT

be illuminated. The LED within the photoelectric sensor will blink rapidly when the sensor

is not at the optimal position. If the LED is solidly illuminated this indicates it is powered up correctly and is

NOT

aligned with the reflector.

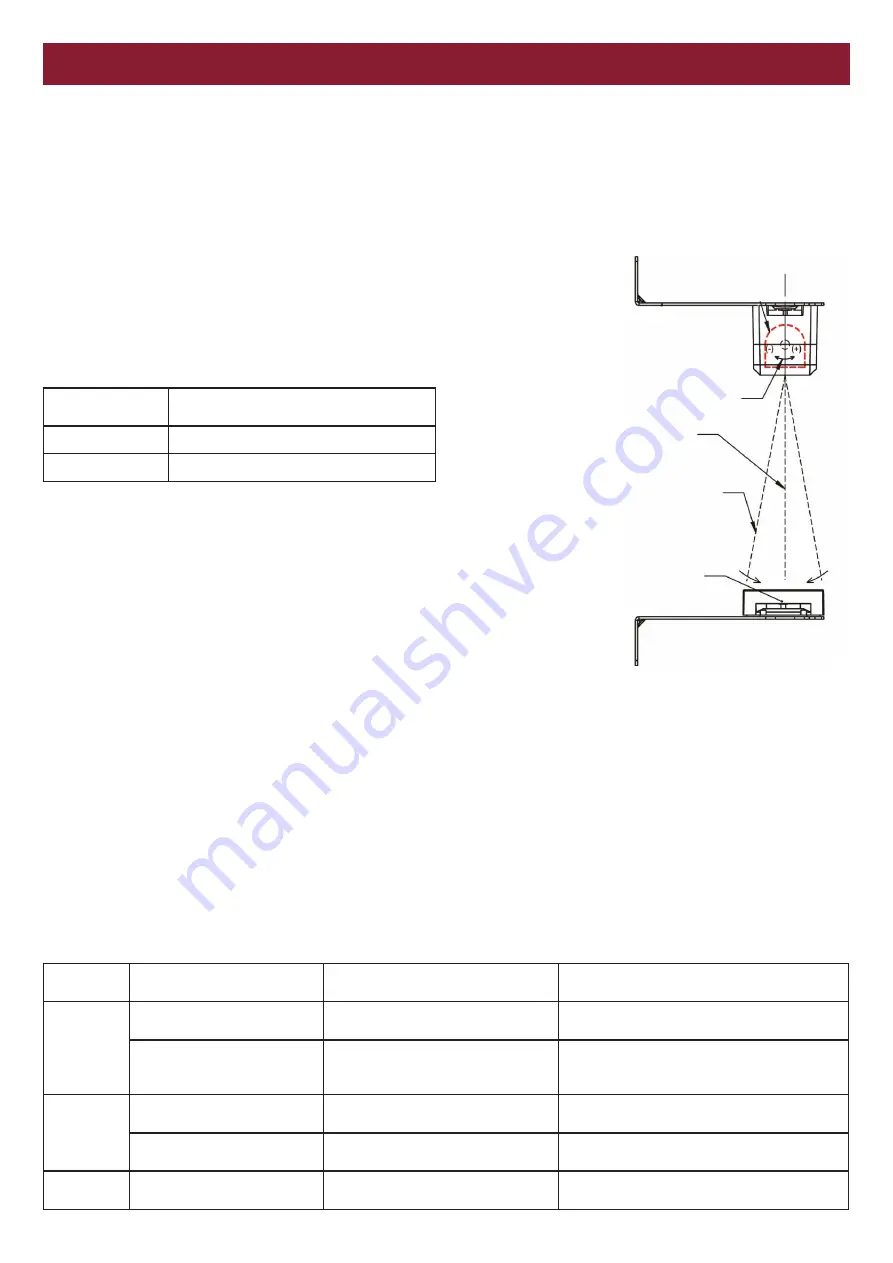

Figure 3 refers to the alignment of the photoelectric sensor.

Connect the photoelectric sensor to the operator and observe the

yellow LED of the photoelectric sensor.

LED alignment pattern:

LED Solid

Photoelectric sensor NOT aligned or

obstructed

LED flashing

Photoelectric sensor NOT aligned 100%

LED OFF

Photoelectric sensor aligned

If the photoelectric sensor is not aligned, rotate the photoelectric

sensor clockwise/counter-clockwise as shown in figure 3 until the

LED stops flashing and is not illuminated. If the LED flashes, the

photoelectric sensor is aligned but may need fine adjustments.

Fine adjustment: The photoelectric sensor can be marginally

aligned and can cause misalignment at a later stage due to small

structural movement. By rotating the photoelectric sensor more

inward, try to find the centerline alignment of the beam (figure 3)

To test the System, with the door in the fully open position, place an obstacle in the path of the photoelectric sensor and give the

operator a CLOSE command. The operator should not move. Now remove the obstacle and give the operator a close command. The

door should close. Introduce an obstruction into the path of the photoelectric sensor and the door should stop and reverse.

Rotate the photoelectric sensor within the

housing to align the sensor

DO NOT BEND THE BRACKET TO ALIGN

Centre aligned

Marginally aligned. Needs fine

adjustment towards the centre

Reflector

FIG 3

Photoelectric sensor

Interruption of a GPS15 will prevent Grifco operators from completing a close cycle.

Note: For S-Drive, both the Open and Close cycles will be stopped, depending on configuration.

The LED positioned within the photoelectric sensor displays the status of the sensor and also assist with installation.

If the photoelectric sensor displays the correct LED indicators during normal operation, but does not stop the door from closing, check if

the cable has been connected to the correct input terminals.

LED status Symptom

Cause

Resolution

Off

Photoelectric sensor aligned.

Door operating as expected.

Wired correctly and aligned with the

reflector.

None. Working correctly.

Photoelectric sensor aligned.

Door

NOT

operating as

expected

Not wired correctly.

Check wiring. The Photoelectric sensor is

polarity sensitive.

On Solid

Photoelectric sensor not

aligned

Wired correctly but

NOT

aligned with

the reflector.

Adjust the photoelectric sensor to the reflector

until the LED goes out.

Obstruction detected

Object in the path of the PE beam

Check the path of the PE beam and remove

the obstruction.

On Flashing

Photoelectric sensor not 100%

aligned.

Photoelectric sensor not optimally

aligned with the reflector.

Adjust the photoelectric sensor to the reflector

until the LED goes out.

OPERATION