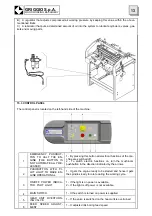

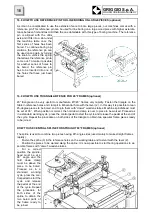

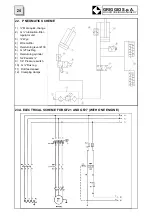

15.2 PNEUMATIC CONNECTION

1) Connect the machine to the compressed air system and make sure that the connection tube is com-

patible with the one provided alongside the machine itself and located on the lubrication-filter-regulator

unit at the back of the machine, in the lower left-hand side.

Pressure should range between 6 and 7 bar maximum.

1) The lubrication-filter-regulator unit is made up by:

A) A filter, whose function is to purify air from dust and humidity that might damage the valves or gas-

kets in pneumatic cylinders.

15.CONNECTING THE MACHINE TO EXTERNAL ENERGY SOURCES

After assembling and installing the machine correctly, the machine has to be connected to:

-

power supply mains

-

compressed air system

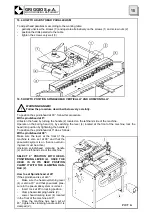

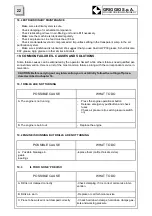

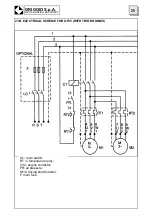

15.1 CONNECTING THE MACHINE TO POWER SUPPLY MAINS

Engine (or Engines) voltage and frequency are indicated on the plate located on the engines.

The user’s electric installation must comply with CEI 64.8 (CENELEC HD 384, IEC 364-4-41) standards.

The electric installation must have:

-

Equipotential earthing system

-

Automatic protection devices installed on the machine and connected so as to guarantee that the

machine is automatically cut off from power supply in compliance with the above-mentioned standards.

Connection to the power supply is made with a three-phase plug (or with a single-phase plug according

to the board required).

Wire for the earthing system is yellow-green.

Allowed oscillation of electric voltage is +/- 10%

Connect the machine cable to the power supply mains.

Switch the machine on and make sure the machine‘s engines are revolving clockwise. Make sure that

spindles rotation matches the direction indicated on the spindlehead. (R= right L= left). If rotation direc-

tion does not match, invert connection cables to the engine.

Refer to the electrical diagrams enclosed in this manual.

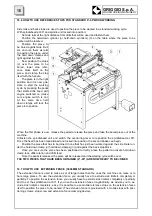

14. ASSEMBLY AND PRELIMINARY STEPS TO OPERATE THE MACHINE FOR

THE FIRST TIME

When the machine is delivered, it is partially assembled. It is therefore necessary to assemble those

pieces that are delivered disassembled for packaging reasons.

Before starting assembling operations, the purchaser must make sure that all machine parts are intact

and have not been damaged during shipment.

In particular, we advise you to check the most fragile components, such as electrical or mechanical

parts, pneumatic tubes or the machine’s safety devices.

When assembly operations are over, the machine must be cleaned by removing protective oil, so that

wood pieces do not get stained while being worked.

CAUTION

: THE MACHINE IS SUPPLIED WITHOUT A SUCTION PLANT. TO KEEP DUST CONCEN-

TRATION BELOW THE T.L.V. SET IN THE COUNTRY WHERE THE MACHINE IS LOCATED, THE

USER MUST INSTALL A SUITABLE SUCTION PLANT ACCORDING TO USAGE, MATERIAL AND

FREQUENCY OF USE.

Saw dust disposal

Saw dust and work scraps disposal is to be carried out in compliance with the regulations in force in the

country where the machine is used. We advise you to ask the relevant bodies of your country for the

relevant legislation so that you know what steps are to be taken.

GRIGGIO S.p.A.

WOODWORKING MACHINERY

12

Summary of Contents for GF 21

Page 2: ......

Page 4: ......

Page 23: ...16 10 WOODWORKING EXAMPLES 19 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 24: ...GRIGGIO S p A WOODWORKING MACHINERY 20 ...

Page 33: ...29 GRIGGIO S p A WOODWORKING MACHINERY 26 SPARE PARTS CATALOGUE ...

Page 35: ...TABLE 1 FRAME 31 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 37: ...TABLE 2 MACHINE TABLE 33 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 39: ...TABLE 3 RACK 35 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 41: ...TABLE 4 LIMITERS 37 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 43: ...TABLE 5 SPINDLES UNIT 39 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 45: ...TABLE 6 HOLD DOWN CLAMPS FRAME 41 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 47: ...TABLE 7 BACK STOP 43 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 49: ...TABLE 8 HOLD DOWN CLAMPS 45 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 51: ...TABLE 9 SPINDLEHEAD 47 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 53: ...TABLE 10 EXTENSION FENCE 49 GRIGGIO S p A WOODWORKING MACHINERY ...

Page 55: ......