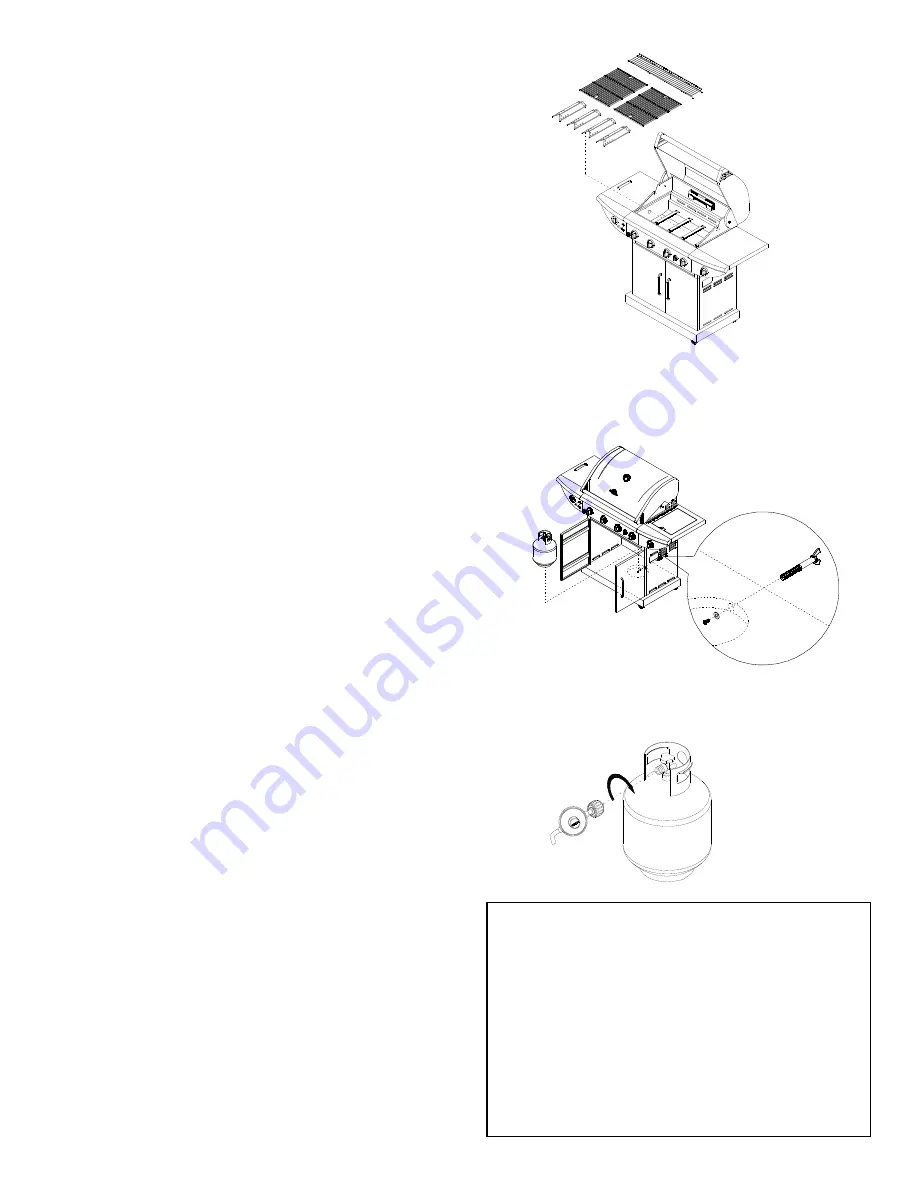

Connecting LP Gas Tank to LP Grill

1.Remove the screw on tank bolt & take off the

washer. Insert the tank bolt from rear of the grill and

reinstall the washer & screw set. From Rear of the

cart, place foot ring of 20 lb tank into the hole in

bottom panel. Make sure the tank valve is in OFF

position. Use the tank bolt to secure the tank in a

fixed position (Fig.22).

2. Check the tank valve to ensure it has proper

external mating threads to fit the hose and regulator

assembly provided.

3. Make sure all burner valves are in OFF position.

4. Inspect the valve connection port and regulator

assembly. Look for damage or debris. Remove any

debris. Inspect hose for damage. Never use

damaged or plugged equipment.

5. When connecting regulator and hose assembly to

tank valve hand tighten quick coupling nut clockwise

to a full stop (Fig.23) Do not use a wrench to tighten

because it could damage the quick coupling nut and

result in a hazardous condition.

6. Open tank valve fully (counterclockwise). Use a

soapy water solution to check all connections for

leaks before attempting to light your grill. If a leak is

found, turn tank valve off and do not use your grill

until the leak is repaired.

CAUTION: When the appliance is not in use, gas

must be turned off at the supply tank.

Installing Cooking Components

Important: Before cooking on your grill the first time,

wash cooking grids and cooking rack with warm ,

soapy water. Rinse and dry thoroughly. Season with

cooking oil regularly. After cooking is completed, turn

grill to HIGH setting for 3 to 5 minutes to burn off

excess grease or food residue.

1. Install heat diffusers above burners. Holes in rear

corners of diffusers attach onto pegs in the back

ledge of firebox. Ensure that grill head heat shield is

inserted securely into slots. If grill was shipped with

shield taped in place, remove tape before using grill.

2. Evenly space cooking grids on the ledge above

heat diffusers. (Fig.21)

3. Insert legs of warming rack into the holes in the

top of grill bowl side panels. (Fig.21)

12

Figure 21

Figure 22

Regulator Connection

Figure 23

Congratulations

Your GrillMaster gas grill is now ready for use.

Before the first use and at the beginning of each

season (and whenever the LP gas tank has been

changed):

1. Read all safety, lighting and operating

instructions.

2. Check gas valve orifices, burner tubes and

burner ports for any obstructions.

3. Perform gas leak check according to

instructions found on next page of the manual.

100

50

600

500

400

C

300

200

700

250

150

50

F

350