ROUTINE MAINTENANCE GUIDE

This table is intended to help you to keep your machine in good, safe working order. It lists the main maintenance and

lubrication procedures with the frequencies at which they are required. Alongside each one, you will find a series of

boxes where you can note the date or the number of operating hours when the procedure was carried out. CAUTION!

Perform the first general inspection after the running-in period, after the first 50 working hours. Change the

engine oil and filter.

Then follow the table below:

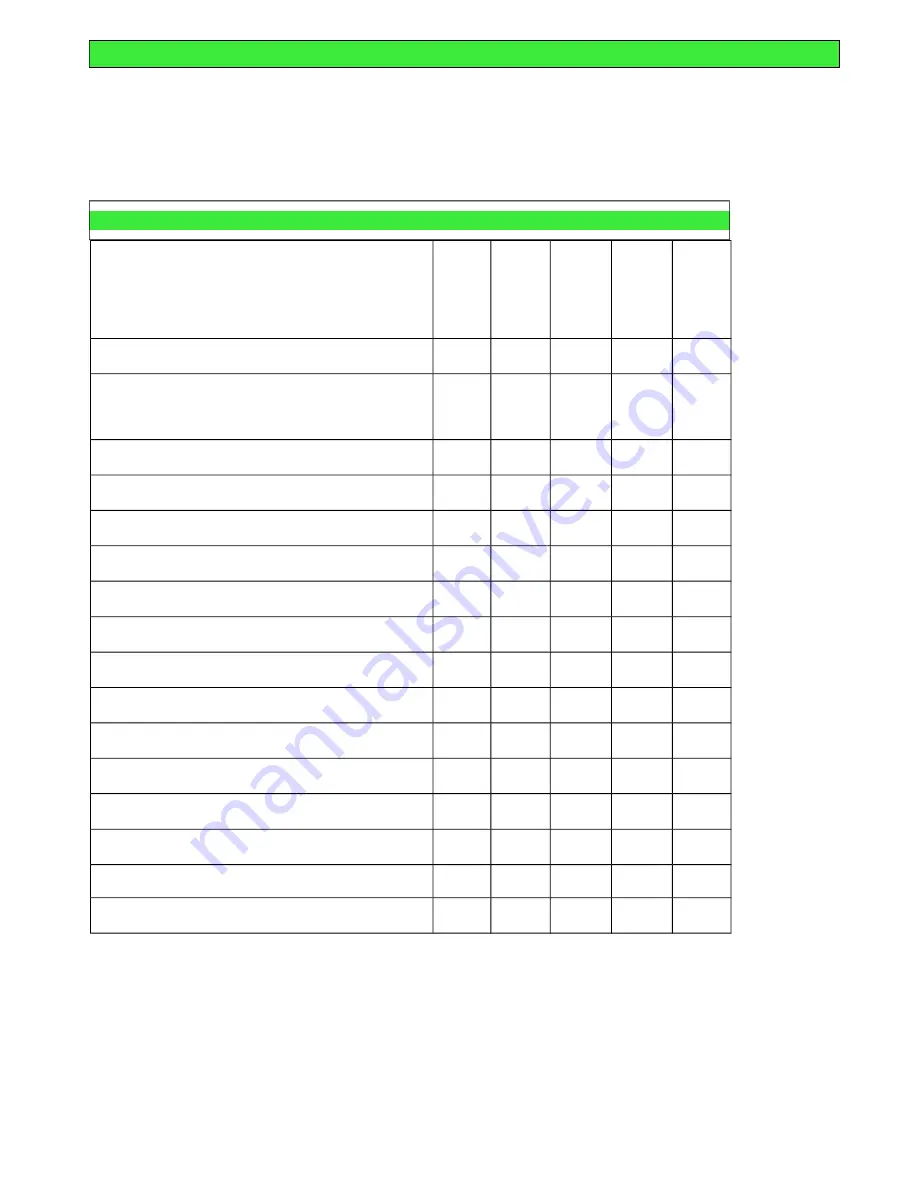

ROUTINE MAINTENANCE GUIDE

PROCEDURE

EACH 8

HOURS

AFTER

THE 50

HOURS

EACH

100

HOURS

EACH

200 ORE

EACH

250

HOURS

OR

EACH

YEAR

Check the wheel bolts tightness

•

•

Check the rubber hoses (brakes, feed system and hydraulic

system)

•

Check the tyre pressure

•

Check the brakes wear

•

Check the battery voltage

•

Check the engine, gearbox and pipe

•

Check and clean the engine air filter

•

Check the brake fluid level

•

Check the radiator liquid level

•

Check the gearbox oil level

•

Check the engine oil level

•

Change the radiator fluid

•

Change the engine oil

•

•

Change the brakes fluid

•

Change the air filter

*

Change the fuel filter

•

Refer to the engine handbook for the complete list and relative procedures.

General lubrication is strongly recommended whenever the machine is to be out of use for a long period.

recommended procedure

* procedure to be made if necessary

11

Summary of Contents for PK 600

Page 40: ...Comandi Fig 2 Comandi fig 1 1 2 3 4 5 6 7 8 9 10 11...

Page 43: ...Fig 3 Fig 4 Fig 5 Fig 6 Fig 7 Fig 8 C A B A B...

Page 44: ...Fig 9 Fig 10 Fig 11 Fig 12 Fig 13 Fig 14 B B A...

Page 45: ...Fig 15 Fig 16 Fig 17 Fig 18 Fig 19 Fig 20 B A A...

Page 46: ......

Page 47: ...Fig 21 Fig 22 Fig 25 Fig 26 Fig 23 Fig 24...

Page 48: ...Fig 28 Fig 30 Fig 31 Fig 28 Fig 26 Fig 27 A...

Page 49: ......

Page 50: ......

Page 52: ......