Clean-In-Place Procedure (Daily Cleaning)

This equipment has been approved for a Clean-In-Place procedure that does not require complete disassembly on a

daily basis. The unit still requires regular complete disassembly for cleaning and sanitizing. To perform the C-I-P

procedure follow the instruction below:

1. Empty any product in the machine and turn to OFF.

2. Disassemble the dispensing valve assembly following the instructions in Disassembly and Cleaning.

NOTE:

Leave the valve block in place. Only disassemble the plunger, handle, spring, o-rings and pin.

3. Remove carburetor assembly from hopper and remove o-rings.

4. Take all components to the cleaning area.

5. Carefully inspect the o-rings for cracks, chips or cuts and replace if necessary.

6. Prepare 1 gallon solution of hot tap water and a good grade of dishwashing detergent.

7. Thoroughly wash all parts including handle, pin, valve plunger, spring, carburetor assembly and all o-rings in

detergent solution.

8. Use a medium sized brush to clean the bottom of the valve body and the inside of the plunger bore with detergent

solution taking care to remove any remaining lubricant.

9. Reassemble following the instructions under Sanitizing and Refilling.

NOTE:

Run the unit with sanitizer on “CLEAN” for 20 minutes before draining and refilling.

MAINTENANCE

WARNING: Disconnect power for maintenance. Do not attempt to perform maintenance on the freezer

until electrical power has been disconnected.

Suggested Daily Maintenance

1. Clean, lubricate and sanitize the freezer following guidelines.

2. Clean the exterior of the freezer using a soft wet cloth. (Wipe down spinner if attached)

3. Empty drip tray.

Parts Replacement Schedule

Refer to the Crathco Parts Price List when ordering the above parts

!

Part

Description

Monthly

Every 3

Months

Every 6

Months

Annually

Quantities to

be Replaced

Shaft Seal

(W0340201 or W0340210)

Replace

1

Drive Shaft

(W0451067)

Inspect & replace if

necessary

1

Drive Belts

(W0450209)

Inspect & replace if

necessary

1

Scraper blades on dasher

(if equipped)

(W1431084)

Replace

2

Square cut o-ring on valve

body/face plate

(W0340055)

Inspect & replace if

necessary

1

Front stator flange bearing

(W0430032)

Replace

1

Rear stator flange bearing

(W0430024)

Replace

1

Dispense valve o-rings

(W0340022)

Replace

Thick Product

Plunger: 2

Standard Product

Plunger: 3

Carb tube o-rings

(W0340011)

Replace

2 or 3

Condenser

Inspect & clean

if necessary

(Air-cooled units only)

1

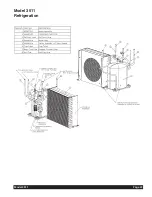

Model 3511

Page 11

Summary of Contents for 3511

Page 2: ......

Page 20: ...Page 18 Model 3511 Model 3511 Electrical Box Assembly Contactor ...

Page 21: ...Model 3511 Page 19 Model 3511 Wiring Diagram ...

Page 22: ...Page 20 Model 3511 Model 3511 Compressor Wiring ...

Page 23: ...Model 3511 Page 21 Model 3511 Ladder Diagram ...

Page 24: ...Page 22 Model 3511 Model 3511 Spinner Wiring ...

Page 25: ...Model 3511 Page 23 Model 3511 Refrigeration ...

Page 26: ...Page 24 Model 3511 Model 3511 Refrigeration Schematic ...

Page 27: ...Model 3511 Page 25 ...