Installation

Water Inlet Connection:

The National Sanitation Foundation requires the following for an NSF approved water hook-up:

1. A quick disconnect water connection or enough coiled tubing so that the machine can be moved for cleaning

underneath.

2. An approved backflow prevention device, such as a double check valve to be installed between the machine and

water supply. A 1/4" male flare adapter is provided (packed inside drain tray) to be attached by installer to the

back of the machine for hook-up to water supply. On units plumbed to permanent water line, installation of a water

filter/softener system is recommended to prevent lime and scale build up in the machine. On units pumping from

remote water container, filtered water is recommended to prevent lime and scale buildup in the machine.

3. Water pipe connections and fixtures directly connected to potable water supply shall be sized, installed and

maintained in accordance with Federal, State, and Local codes.

Water hook-up:

1. Install the (2) front 4" legs to provide approximately 1/2" clearance with the bottom of the machine.

2. Install drain tray bracket to the front of the machine by sliding the bracket between the front 4" legs and the

bottom of the machine. The bracket should self locate with screw heads on the bottom of the machine. Tighten

the front 4" legs to secure the drain tray bracket.

3. Install the (2) back 4" legs and tighten.

4. Install the plastic drain tray onto the drain tray bracket. (Note: The drain tray is provided with a removable plug to

allow for plumbing the drain tray to a drain.)

5. Connect the metal swivel fitting provided to a flexible water supply hose. Ensure the water supply hose has

sufficient length to allow the machine to be moved for cleaning or service. Supplying hot water to the machine will

greatly increase the capacity of the machine. The use of copper tubing is required to prevent rupture when using

a hot water supply. A maximum inlet water temperature of 160Þ F is recommended.

6. Ensure that the water supply to the machine is within 20 to 100psi. Install a pressure regulator if pressure is too

high.

American Metal Ware Liquid Coffee Dispenser

Page 3

!

WARNING: ELECTRIC SHOCK HAZARD

Only qualified service personnel should perform installation of this appliance.

Improper installation could result in serious injury or death.

!

WARNING: ELECTRIC SHOCK HAZARD

Never use the ground conductor as a neutral conductor. Serious injury or

death could occur in the event of a fault condition.

!

WARNING: ELECTRIC SHOCK HAZARD

Always disconnect power to the machine before servicing or cleaning. Risk

of electric shock is present which can cause serious injury or death.

Summary of Contents for American Metal Ware LCD2-1

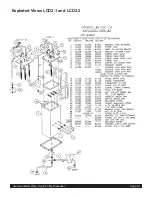

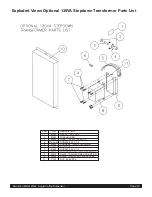

Page 12: ...Exploded Views LCD2 1 and LCD2 3 American Metal Ware Liquid Coffee Dispenser Page 12 ...

Page 13: ...American Metal Ware Liquid Coffee Dispenser Page 13 Exploded Views LCD2 1 and LCD2 3 ...

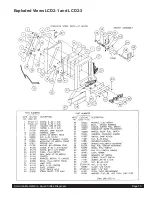

Page 14: ...American Metal Ware Liquid Coffee Dispenser Page 14 Exploded Views LCD2 1 and LCD2 3 ...

Page 15: ...American Metal Ware Liquid Coffee Dispenser Page 15 Exploded Views LCD2 1 and LCD2 3 ...

Page 18: ...American Metal Ware Liquid Coffee Dispenser Page 18 Wiring Diagram 120 240V ...

Page 19: ...American Metal Ware Liquid Coffee Dispenser Page 19 Wiring Diagram 120 240V ...

Page 20: ...American Metal Ware Liquid Coffee Dispenser Page 20 Wiring Diagram Rev Release ...

Page 21: ...American Metal Ware Liquid Coffee Dispenser Page 21 Wiring Diagram ...