Page 13

Auto Series Brewer Manual

TROUBLESHOOTING GUIDE

Problem

Possible Source

Check

Solution

No Hot Water

1. Tank heater

2. Hi-limit thermostat

or main thermostat

1. Check the voltage at the tank

heater terminals. Voltage should be

120V (230V for E models). Check

serial tag for proper voltage.

2. Check the voltage between the

white wire on the tank heater

terminal and the incoming terminal

(black wire) on the hi-limit

thermostat, then the outgoing

(black wire) terminal on the hi-limit

thermostat.

1. (A) If correct voltage is present at the tank heater

terminals and water is not being heated, replace tank

heater.

(B) If voltage is not present at tank heater terminals,

refer to step 2.

(C) If incorrect voltage is present at tank heater

terminals, check voltage at outlet.

2. (A) If voltage is present on incoming terminal on the

hi-limit thermostat but not on the outgoing terminal,

replace hi-limit thermostat.

(B) Check voltage between black and white wire on

receptacle. If voltage is not present check outlet or

circuit breaker.

(C) If voltage is not present on incoming terminal of

hi-limit thermostat, replace main thermostat.

Steaming or

Spitting Around

Funnel

1. Main thermostat

2. High altitude

1. Thermostat contact stuck or out of

calibration

2. For altitude above 5,000 feet (1,500m)

1. (A) Adjust thermostat to lower temperature setting.

(B) Thermostat should be calibrated or replaced.

Dripping

1. Not siphoning properly

2. Leaky fill valve

1. Water should flow from sprayhead freely

2. Turn off water supply to see if

dripping stops

1. (A) Clean sprayhead holes

(B) Check tightness of sprayhead tube.

(C) Check brass elbow in tank for debris

2. Replace or repair inlet valve as needed

Dry Coffee

Remaining on

Brew Basket

1. Filters

2. Not siphoning properly

3. Improper loading of

brew basket

1. Are correct filters being used

2. Refer to “dripping” step 1

3. Filter and coffee in brew basket

1. Use correct filter

2. Refer to “dripping” step 1

3. Filter should be centered in brew basket and

coffee bed should be level.

Warmer Station

1. Warmer - defective

2. Warmer On/Off switch

3. Bad harness

1. Voltage at warmer terminals should

be 120V (230V for E models).

2. If voltage is not present on warmer

terminals, check continuity of switch

3. Check connections between harness

and switch, and between switch and

warmer.

1. If voltage is present on terminals, but warmer is

not heating, replace warmer.

2. If switch does not make and break continuity

when turned on and off, replace switch.

3. All connections should be tight.

Overflowing

1. Receiving container

not completely empty

at start of brew cycle.

2. Not siphoning properly

3. Adjust timer

1. Operating instructions

2. Refer to “dripping” step 1.

3. Check valve on-time with watch

1. Always start brew cycle with empty container.

2. Refer to “dripping” step 1.

3. Refer to “Brew Volume Adjustment” section

Low Pot Level

1. Adjust timer

1. Check valve on-time with watch

1. Refer to “Brew Volume Adjustment” section

Excessively Long

Brew Times

1. Lime scale build-up

1. Remove spray head deflector and check

nozzle.

1. Delime machine.

Little or No Water

From Faucet

1. Lime scale build-up

2. Clogged inlet valve

Be sure water is turned on.

1. Delime heat exchanger.

2. Replace or repair inlet valve.

If you still need help, call an authorized dealer in your area or Grindmaster Corporation’s Technical Service Department. You c

an reach

Technical Service at (502) 425-4776 or (800) 695-4500 (USA and Canada only) Monday - Friday, 8:00 AM - 8:00 PM EST.

Please have the model and serial number ready so that accurate information can be given.

Prior authorization must be obtained from Grindmaster Corporation’s Technical Service Department for all warranty claims.

Summary of Contents for AT-2W

Page 2: ......

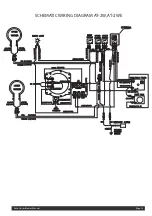

Page 15: ...Auto Series Brewer Manual Page 15 SCHEMATIC WIRING DIAGRAM AT 2W AT 2WE ...

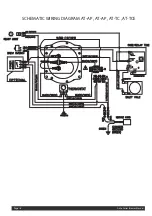

Page 16: ...Auto Series Brewer Manual Page 16 SCHEMATIC WIRING DIAGRAM AT AP AT AP AT TC AT TCE ...

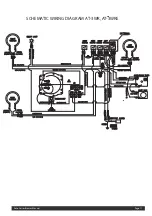

Page 17: ...SCHEMATIC WIRING DIAGRAM AT 3WR AT 3WRE Auto Series Brewer Manual Page 17 ...

Page 18: ...Auto Series Brewer Manual Page 18 SCHEMATIC WIRING DIAGRAM AT 3W AT 3WE ...

Page 19: ......