ing a fire condition) should be verified

at least once a year as follows:

1. If water must be prevented from flow-

ing beyond the riser, perform the fol-

lowing steps.

a.

Close the Main Control Valve.

b.

Open the Main Drain Valve.

c.

Open the Main Control Valve

one turn beyond the position at

which water just begins to flow

from the Main Drain Valve.

d.

Close the Main Drain Valve.

2. Determine the type of actuation/de-

tection system, and operate the

F470 Valve accordingly.

NOTE

Be prepared to quickly perform

Steps 3, 4, and 5, if water must be

prevented from flowing beyond

the riser.

Wet Pilot Actuation — Open the

Inspector’s Test Connection.

Dry Pilot Actuation — Open the

Inspector’s Test Connection.

Electric Actuation — Test the del-

uge releasing panel (automatic con-

trol unit) in accordance with the

manufacturer’s instructions to ener-

gize the solenoid valve.

3. Verify that the F470 Valve has

tripped, as indicated by the flow of

water into the system.

4. Close the Diaphragm Chamber Sup-

ply Control Valve.

5. Close the system’s Main Control

Valve.

6. Reset the F470 Deluge Valve in ac-

cordance with the Valve Setting Pro-

cedure.

Five Year Internal Valve Inspection

Once every five years during the an-

nual operational test procedure and

prior to the F470 Valve being reset, the

internal parts of the F470 Valve should

be cleaned and then inspected for

wear and damage. Make certain that

the two 1/8 inch (3,2mm) diameter

pressure equalizing vents in the top of

the Clapper are open. Special consid-

eration should be given to the condi-

tion of the Diaphragm and the Clapper

Facing. The Diaphragm and/or Clap-

per Facing should be replaced if there

are any signs of deterioration due to

age or chemicals in the water.

NOTE

If the water supply contains chemi-

cals which tend to attack an EPDM

type rubber or the five year inspection

indicates a build-up of debris within

the valve which could affect its proper

operation, then the frequency of the

internal valve inspection procedure

should be increased as appropriate.

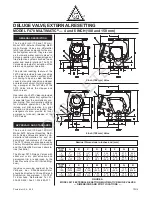

Worn or damaged parts must be re-

placed and the F470 Valve must be

reassembled in accordance with Fig-

ure B. The Cap Screws securing the

Diaphragm and Handhole Covers

should be uniformly tightened using a

cross-draw sequence.

Quarterly Solenoid Valve Test Pro-

cedure For Electric Actuation

Proper operation of the Solenoid Valve

for electric actuation should be verified

at least quarterly as follows:

1. Close the Main Control Valve.

2. Open the Main Drain Valve.

3. Test the automatic control unit (del-

uge releasing panel) in accordance

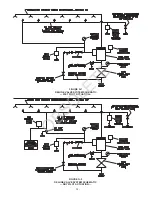

FIGURE G-3

DELUGE VALVE SYSTEM SCHEMATIC

— ELECTRIC ACTUATION—

-13-

OBSOLETE