with the manufacturer’s instructions

to energize the solenoid valve.

4. Verify that the flow of water from the

Solenoid Valve drain connection in-

creases to a full flow.

5. Verify that the Diaphragm Chamber

pressure has decreased to below

25% of the water supply pressure.

6. Reset the electric detection system

in accordance with the manufac-

turer’s instructions to de-energize

the solenoid valve. Check the Sole-

noid Valve drain for leaks. Any leaks

must be corrected before proceed-

ing to the next step.

7. Slowly open the Main Control Valve.

Close the Main Drain Valve as soon

as water discharges from the drain

connection. Observe the Automatic

Drain Valve for leaks. If there are

leaks, determine/correct the cause

of the leakage problem. If there are

no leaks, the F470 Valve is ready to

be placed in service and the Main

Control Valve must then be fully

opened.

Quarterly Dry Pilot Actuator Test

Procedure For Dry Pilot Actuation

Proper operation of the Dry Pilot Ac-

tuator for dry pilot actuation should be

verified at least quarterly as follows:

1. Close the Main Control Valve.

2. Open the Main Drain Valve.

3. Open the Inspector’s Test Connec-

tion on the Dry Pilot Line.

4. Verify that the flow of water from the

Dry Pilot Actuator drain connection

increases to a full flow.

5. Verify that the Diaphragm Chamber

pressure has decreased to below

25% of the water supply pressure.

6. Close the Inspector’s Test Connec-

tion and allow the dry pilot line pres-

sure to re-establish. Check the Dry

Pilot Actuator drain for leaks. Any

leaks must be corrected before pro-

ceeding to the next step.

7. Slowly open the Main Control Valve.

Close the Main Drain Valve as soon

as water discharges from the drain

connection. Observe the Automatic

Drain Valve for leaks. If there are

leaks, determine/correct the cause

of the leakage problem. If there are

no leaks, the F470 Valve is ready to

be placed in service and the Main

Control Ave must then be fully

opened.

Quarterly Waterflow Alarm Test

Procedure

Testing of the system waterflow alarms

should be performed quarterly. To test

the waterflow alarm, open the Alarm

Test Valve, which will allow a flow of

water to the Pressure Alarm Switch

and/or Water Motor Alarm. Upon satis-

factory completion of the test, close

the Alarm Test Valve.

Quarterly Low Pressure Alarm Test

Procedure And Condensate Drain

Procedure For Dry Pilot Actuation

For Dry Pilot Actuation, testing of the

Low Pressure Alarm Switch and drain-

age of the pilot line condensate should

be performed quarterly as follows.

1. Close the Diaphragm Chamber Sup-

ply Control Valve.

2. Close the Main Control Valve.

3. Open the Main Drain Valve.

4. Drain the dry pilot line condensate

as follows.

a.

Close the Gauge Test Valve lo-

cated below the Dry Pilot Line

Pressure Gauge.

b.

Remove the 1/4" Plug from the

Gauge Test Valve.

c.

Crack Open the Gauge Test

Valve and allow all conden-

sate, if any, to drain out.

d.

Close the Gauge Test Valve,

replace the Plug, and then

open the Gauge Test Valve.

5. Open the Inspector’s Test Connec-

tion, and slowly relieve pneumatic

pressure. Verify that the Low pres-

sure Alarm Switch is operational and

that the low pressure set points are

as follows:

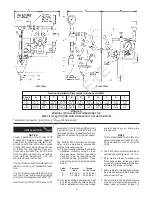

•

Low pressure alarm setting at

approximately 6 psi (0,4 bar)

below the minimum pilot line

service pressure requirement

shown in Graph C.

•

Fire alarm setting at approxi-

mately 15 psi (1,0 bar) below

the minimum pilot line service

pressure requirement shown

in Graph C.

6. Close the Inspector’s Test Connec-

tion, and allow the Dry Pilot Line to

automatically repressurize.

7. Open the Diaphragm Chamber Sup-

ply Control Valve.

8. Slowly open the Main Control Valve.

Close the Main Drain Valve as soon

as water discharges from the drain

connection. Observe the Automatic

Drain Valve for leaks. If there are

leaks, determine/correct the cause

of the leakage problem. If there are

no leaks, fully open the Main Control

Valve.

WARRANTY

Seller warrants for a period of one year

from the date of shipment (warranty

period) that the products furnished

hereunder will be free from defects in

material and workmanship.

For further details on Warranty, see

Price List.

ORDERING PROCEDURE

All orders for Model F470 Multimatic

Deluge Valves, trim, accessories, and

replacement parts must include the

description and Product Symbol

Number (PSN), where applicable.

Valves:

Unless otherwise specified, the F470

Valves will be provided with ANSI

flange drilling.

Specify: (specify size) Model F470 Ex-

ternal Resetting Multimatic Deluge

Valve with (specify abbreviation — re-

fer to Table A, Page 2) flange drilling,

PSN (specify).

ANSI

4" (100 mm) . . . . . . . . . . . . . . PSN 52-470-1-013

6" (150 mm) . . . . . . . . . . . . . . PSN 52-470-1-015

ISO

4" (100 mm) . . . . . . . . . . . . . . PSN 52-470-4-113

6" (150 mm) . . . . . . . . . . . . . . PSN 52-470-4-115

AS

4" (100 mm) . . . . . . . . . . . . . . PSN 52-470-4-313

6" (150 mm) . . . . . . . . . . . . . . PSN 52-470-4-315

JIS

4" (100 mm) . . . . . . . . . . . . . . PSN 52-470-4-713

6" (150 mm) . . . . . . . . . . . . . . PSN 52-470-4-715

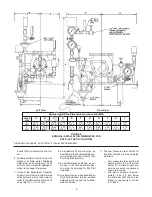

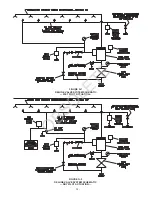

Trim:

Unless otherwise specified, all trim ar-

rangements are provided factory as-

sembled as shown in Figure F-2. Un-

assembled trim packages as shown in

Figure F-1 can be provided on “special

order”. Product Symbol Numbers

(PSN) need not be specified when or-

dering unassembled trim.

-14-

OBSOLETE