The Model F470 Multimatic Deluge

Valves are accepted by the City of New

York under MEA 38-92-M.

WARNING

The Model F470 Multimatic Deluge

Valves described herein must be in-

stalled and maintained in compli-

ance with this document, as well as

with the applicable standards of the

National Fire Protection Association,

in addition to the standards of any

other authorities having jurisdiction.

Failure to do so may impair the integ-

rity of these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. The installing contractor or

manufacturer should be contacted

relative to any questions.

TECHNICAL DATA

Deluge Valve:

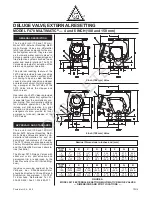

The 4 and 6 inch (100 and 150 mm),

Model F470 External Resetting Multi-

matic Deluge Valves are rated for use

at a maximum service pressure of 175

psi (12,1 bar). The Valve dimensions

are shown in Figure A, and all of the

por ts are NPT threaded per ANSI

Standard B1.20.1. Flanged inlet and

outlet connections are available drilled

per ANSI, AS, ISO, and JIS specifica-

tion options indicated in Table A. When

the flange drilling is provided to AS,

ISO, or JIS specifications, the label

located on the Handhole Cover indi-

cates the specification to which the

flange drilling has been provided.

The F470 Valve is to be installed verti-

cally, as shown in Figure A. Exterior

surfaces of the F470 Valve are painted

red, and the year of manufacture is

indicated on the Handhole Cover.

Components of the F470 Valve are

shown in Figure B. The Body, Hand-

hole Cover, and Diaphragm Cover are

ductile iron per ASTM A536 (UNS

F33100). The Handhole Cover Gasket

is neoprene, and the Clapper Facing,

Diaphragm, and O-Rings are EPDM.

The Seat Ring, Clapper, Diaphragm

Retainer, and the Flange of the Flange

& Push Rod Assembly are bronze per

ASTM B62 (UNS C83600).The Clap-

per Latch is aluminum bronze per

ASTM B148 (UNS C956200), the Re-

set Bushing is brass per ASTM B16

(UNS C36000), and the Bearings are

bronze per ASTM B438, Grade 1, Type

II. The Clapper Facing Retainer, Clap-

per Bolt, Reset Plunger, Clapper

Hinge Pin, Latch Hinge Pin, and the

Push Rod of the Flange & Push Rod

Assembly are fabricated from austeni-

tic stainless steel. The Reset Knob is

phenolic, and the Handhole Cover

Bolts, Diaphragm Cover Bolts, and

Pipe Plugs are carbon steel.

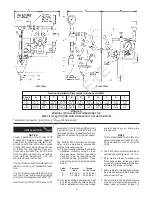

The nominal pressure losses versus

flow are shown in Graphs A-1 and A-2.

The approximate friction losses, based

on the Hazen and Williams formula

and expressed in equivalent length of

Schedule 40 pipe with C = 120, is 12

feet for the 4 inch (100 mm) valve size

and 30 feet for the 6 inch (150 mm)

valve size. The equivalent length of

pipe has been calculated on the basis

of the flow rates typically used with

each size valve.

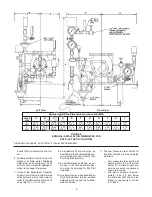

Valve Trim:

The Wet Pilot Actuation Trim, Dry Pilot

Actuation Trim, or Electric Actuation

Trim illustrated in Figure F-1 form a

part of the laboratory listings and ap-

-3

GRAPHS A-1 and A-2

NOMINAL PRESSURE LOSS VERSUS FLOW

GRAPH A-1

GRAPH A-2

OBSOLETE