proval of the F470 Valves and are nec-

essary for their proper operation. Each

package of trim includes the following

items:

•

Water Supply Pressure Gauge

•

Diaphragm Chamber

Pressure Gauge

•

Diaphragm Chamber Connections

•

Actuation Devices (as applicable)

•

Main Drain Valve

•

Alarm Test Valve

•

Alarm Control Valve

•

Automatic Drain Valve

•

Dry Pilot Line Pressure Gauge

(as applicable)

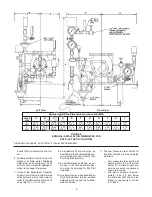

To ease field assembly of the trim ar-

rangements, the appropriate compo-

nents required for Wet Pilot Actuation,

Dry Pilot Actuation, or Electric Actua-

tion are factory assembled as shown

in Figure F-2.

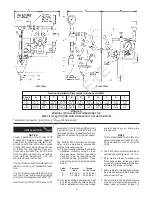

Wet Pilot Actuation

(Figure F-1, Items 1 through 35)

The Wet Pilot Actuation Trim provides

for connection of a detection system

consisting of wet pilot sprinklers (heat

detectors) and manual control stations

interconnected with minimum 1/2 inch

(15 mm) Schedule 40 steel pipe. The

pilot line is connected to the “Wet Pilot

Detection” connection shown in Figure

F-1. Nominal installation dimensions

for the Wet Pilot Actuation Trim are

shown in Figure D.

Wet pilot sprinklers are to be minimum

1/2 inch (15 mm) orifice listed or ap-

proved automatic sprinklers. Manual

Control Stations are to be either the

Model F180 or F184 described in Tech-

nical Data Sheet TD121.

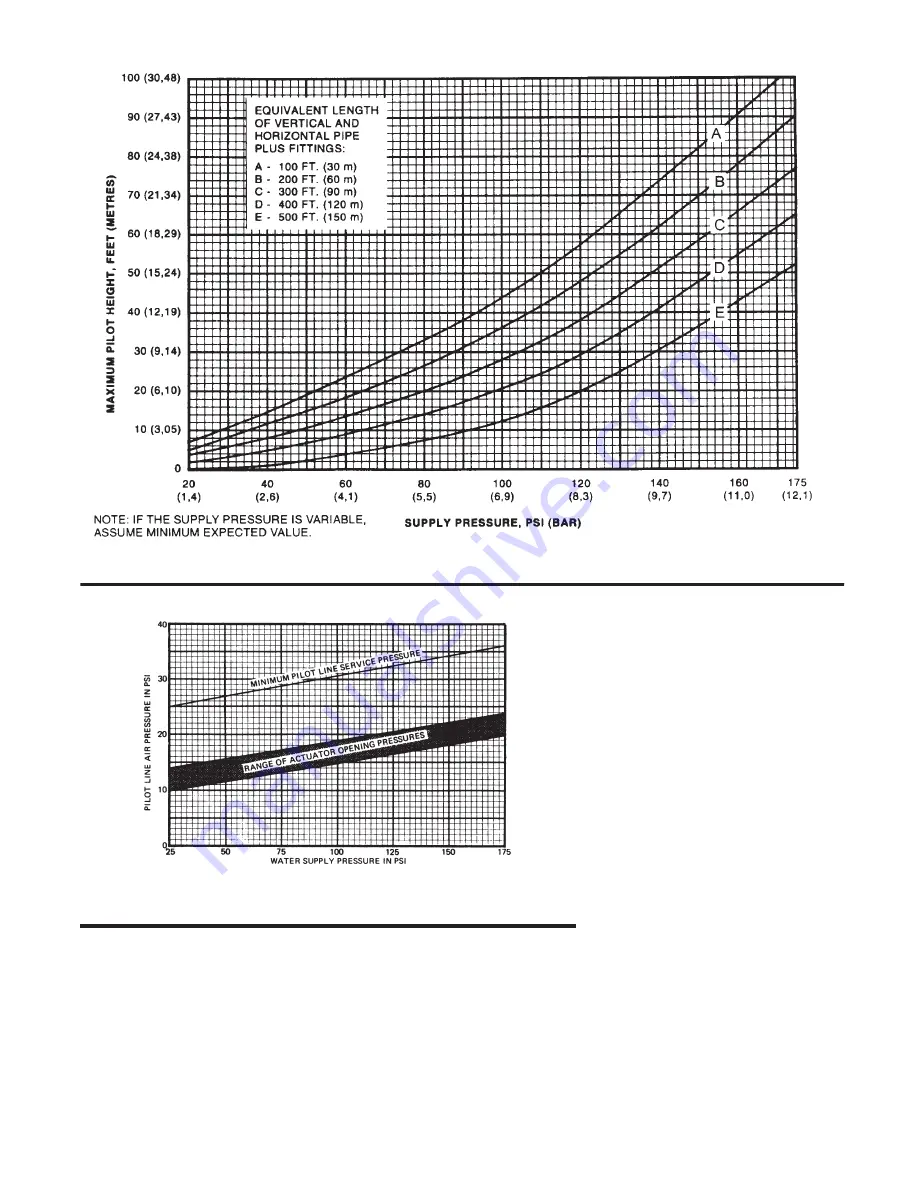

The maximum height of a wet pilot line

above the F470 Valve must not exceed

the limitations given in Graph B as a

function of the minimum water supply

pressure to the F470 Valve and the

length of the pilot line to the most re-

mote pilot sprinkler.

Provision must be made for installing

a 1/2 inch (15mm) orifice, Inspector’s

Test Connection at the most hydrauli-

cally demanding location of a wet pilot

line (usually adjacent to the highest

and most remote wet pilot sprinkler or

manual control station).

-4-

GRAPH B

WET PILOT LINE DESIGN CRITERIA

GRAPH C

DRY PILOT LINE PRESSURE REQUIREMENTS

OBSOLETE