inches (300 mm) below the drip fun-

nel.

6. Suitable provision must be made for

disposal of drain water. Drainage

water must be directed such that it

will not cause accidental damage to

property or danger to persons.

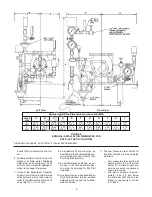

7. Connect the Diaphragm Chamber

Supply Control Valve to the inlet side

of the system’s main control valve in

order to facilitate setting of the F470

Valve (Ref. G-1, G-2, or G-3).

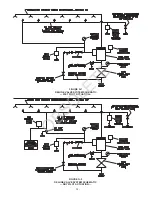

8. An Inspector’s Test Connection, as

described in the Technical Data sec-

tion, must be provided for Wet or Dry

Pilot Actuation systems.

9. An Air Maintenance Device, as de-

scribed in the Technical Data Sec-

tion, must be provided for Dry Pilot

Actuation.

10. A desiccant dryer, when specified for

Dry Pilot Actuation, is to be installed

between a drip leg and the Air Main-

tenance Device.

11. The Low Pressure Alarm Switch for

Dry Pilot Actuation is to be adjusted

as follows:

•

Low pressure alarm setting at

approximately 6 psi (0,4 bar)

below the minimum pilot line

service pressure requirement

shown in Graph C.

•

Fire alarm setting at approxi-

mately 15 psi (1,0 bar) below

the minimum pilot line service

pressure requirement shown

in Graph C.

-8-

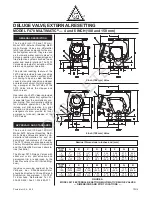

FIGURE E

NOMINAL INSTALLATION DIMENSIONS FOR

DRY PILOT ACTUATION TRIM

Left View

Front View

*

MINIMUM CLEARANCE, ADDITIONAL 2" (50mm) RECOMMENDED

Nominal Installation Dimensions in Inches and (MM)

VALVE

SIZE

4

(100)

6

(150)

A

12.00

(304,8)

12.00

(304,8)

J

7.75

(196,9)

8.56

(217,4)

B

8.69

(220,7)

8.69

(220,7)

K

6.31

(160,3)

6.31

(160,3)

C

14.56

(369,8)

15.44

(392,2)

L

0.25

(6,4)

0.12

(3,0)

D

13.69

(347,7)

14.50

(368,3)

E

30.12

(765,0)

31.12

(790,4)

F

5.44

(138,2)

5.50

(139,7)

G

6.69

(169,9)

7.62

(193,5)

H

8.75

(222,3)

8.88

(225,6)

OBSOLETE