12. Unused pressure alarm switch con-

nections must be plugged.

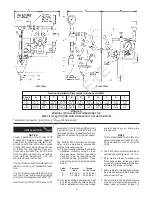

13. The Pressure Relief Valve provided

with the Dry Pilot Actuation Trim is

factory set to relieve at a pressure of

approximately 45 psi (3,1 bar),

which can typically be used for a

maximum normal dry pilot actuation

system pressure of 40 psi (2,8 bar).

The Pressure Relief Valve may be

reset; however, it must be be reset to

relieve at a pressure which is in ac-

cordance with the requirements of

the authority having jurisdiction.

To reset the Pressure Relief Valve,

first loosen the jam nut and then

adjust the cap accordingly — clock-

wise for a higher pressure setting or

counterclockwise for a lower pres-

sure setting. After verifying the de-

sired pressure setting, tighten the

jam nut.

14. Conduit and electrical connections

are to be made in accordance with

the requirements of the authority

having jurisdiction and/or the Na-

tional Electric Code.

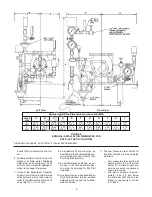

VALVE SETTING PROCEDURE

Steps 1 through 12 are to be per-

formed when initially setting the Model

F470 Multimatic Deluge Valve; after an

operational test of the fire protection

system; or, after system operation due

to a fire.

1. Close the Diaphragm Chamber Sup-

ply Control Valve.

2. Close the Main Control Valve, and if

the system is equipped with Dry Pilot

Actuation, close the Air Supply Con-

trol Valve (Ref. Figure F).

3. Open the Main Drain Valve and all

auxiliary drains in the system. Close

the auxiliary drain valves after water

ceases to discharge. Leave the Main

Drain Valve open.

4. Depress the plunger of the Automat-

ic Drain Valve to verify that it is open

and that the F470 Valve is com-

pletely drained.

5. Push the Reset Knob inward to allow

the Clapper to reseat.

Under normal circumstances, the

reseating of the Clapper can be

heard; however, during an annual

operation test procedure, for exam-

ple, due to minimal flow through a

partially opened main control valve,

the Clapper may not latch open as

shown in Figure C-3. In which case

the reseating sound of the Clapper

will not be heard.

Also under normal circumstances,

water pressure in the riser will have

exerted sufficient force on the Dia-

phragm so as to have emptied most

of the water from the Diaphragm

Chamber which, in turn, will ease

the pushing of the Reset Knob by

eliminating the resistive force pro-

duced by a water filled Diaphragm

Chamber. Therefore, should water

remain in the Diaphragm Chamber,

the Reset Plunger will need to be

depressed with added force to push

the remaining water out of the Dia-

phragm Chamber and through an

open actuation device (e.g., a Dry

Pilot Actuator or Solenoid Valve).

NOTE

If the Reset Knob can not be de-

pressed sufficiently to allow the

Clapper to reseat, operate (open)

the Manual Control Station and

then once again push the Reset

Knob with sufficient force to push

the water out of the Diaphragm

Chamber through the Manual

Control Station drain.

6. Clean the Strainer in the Diaphragm

Chamber Supply connection by re-

moving the clean-out plug and

strainer basket. The Strainer may be

flushed out by momentarily opening

the Diaphragm Chamber Supply

Control Valve.

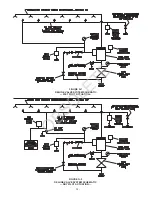

7. Open the Alarm Control Valve (Fig.

F), if it was closed to silence local

alarms.

It is recommended that the Alarm

Control Valve be wire sealed in the

open position with a No. 16 twisted

wire, the ends of which are secured

by a lead seal. The wire seal should

be looped through the hole in the

handle and tightly twisted around the

pipe nipple adjacent to the handle.

8. Reset the actuation system.

Manual Actuation — Push the oper-

ating lever up; however, do not close

the hinged cover at this time.

Wet Pilot Actuation — Replace op-

erated pilot sprinklers and/or reset

the manual control stations.

Dry Pilot Actuation — Replace oper-

ated pilot sprinklers and/or reset the

manual control stations. Re-estab-

lish dry pilot pneumatic pressure.

Electric Actuation — Reset the elec-

tric detection system in accordance

with the manufacturer’s instructions

to de-energize the solenoid valve.

NOTE

In order to prevent the possibility

of a subsequent operation of an

overheated solder type pilot sprin-

kler, any solder type pilot sprin-

klers which were possibly exposed

to a temperature greater than

their maximum rated ambient

must be replaced.

9. Open the Diaphragm Chamber Sup-

ply Control Valve and allow time for

full pressure to build up in the Dia-

phragm Chamber.

10. Operate (open) the Manual Control

Station to vent trapped air from the

Diaphragm Chamber. If necessary,

first open the hinged cover, and then

fully pull down on the operating lever.

SLOWLY close the operating lever,

by pushing it up, after aerated water

ceases to discharge from the Man-

ual Control Station drain tubing.

Close the hinged cover and insert a

new break rod in the small hole

through the top of the enclosing

box.

If wet pilot actuation is being used,

crack open the Inspector’s Test Con-

nection and any other vent valves, to

relieve trapped air. After the dis-

charge of air has stopped, close the

vent valves and the Inspector’s Test

Connection.

11. Inspect drain connections from the

Manual Control Station, Solenoid

Valve, Dry Pilot Actuator, and Alarm

Devices, as applicable. Any leaks

must be corrected before proceed-

ing to the next step.

12. Slowly open the Main Control Valve.

Close the Main Drain Valve as soon

as water discharges from the drain

connection. Observe the Automatic

Drain Valve for leaks. If there are

leaks, determine/correct the cause

of the leakage problem. If there are

no leaks, the F470 Valve is ready to

be placed in service and the Main

Control Ave must then be fully

opened.

NOTE

After setting a fire protection system,

notify the proper authorities and ad-

vise those responsible for monitoring

proprietary and/or central station

alarms.

-9-

OBSOLETE