t

ool

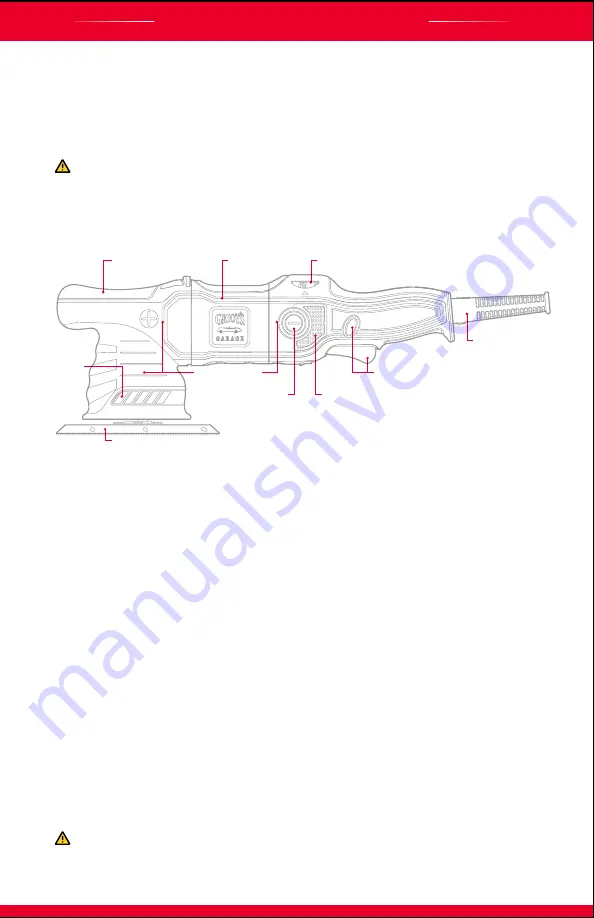

c

omPonent

d

iaGram

INTENDED USE

The Griot’s Garage G9 Random Orbital Polisher is designed for polishing paint, glass,

unfinished metal, fiberglass, and composite surfaces. Common examples of use

include but are not limited to auto, marine, RV, and motorcycle detailing.

FUNCTIONAL COMPONENTS

WARNING:

Never modify the power tool. Damage or personal injury could result.

A. Rest Pads

E. Contaminant Protection Screen

B. Speed Control Dial

F. Trigger Lock Button

C. Premium Sealed Bearings

G. On/Off Trigger Switch

D. Brush Inspection Cap

H. Quick-Connect Power Cord

Speed Control Dial (B)

The maximum speed of your polisher can be changed by rotating the Speed Control

Dial. The polisher is equipped with a constant speed control so you can adjust

the speed to suit the objective. The machine operates from 2,000 - 4,800 opm.

The Constant Speed Control circuitry will ensure consistent speed regardless of

downward pressure or lack thereof. This feature delivers optimal performance,

regardless of user technique and body panel shape.

Recommended speed for application:

Paint Correction: Speed 4 - 5 for light to moderate swirls, scratches, and stains.

Paint Perfection: Speed 3 - 4 for fine swirls, scratches, and stains.

Paint Protection: Speed 2 - 3 for wax or sealant application.

On/Off Trigger Switch (G)

The polisher is equipped with an on/off trigger. Once engaged the machine will

operate in accordance with speed set on Speed Control Dial. The machine operates

from 2,000 - 6,400 opm.

Polisher can be locked on for continuous use by depressing the trigger and engaging

the Trigger Lock Button, while releasing your finger from the trigger. To shut off,

depress trigger and release.

CAUTION:

The backing plate and pad will continue to rotate briefly after the

polisher is turned off.

Patent Pending

fan-cooled

counterbalance

extends tool,

backing plate,

and pad life

Ergonomic design dampened with

double-shot rubber for supreme comfort

Premium sealed bearings

for long-service life

Constant speed control maintains consistent set speed

range of 2,000-6,400 orbits per minute

Powerful 1,000-watt motor

for efficient defect removal

Convenient On/Off

lockable trigger switch

Premium vented backing plate

for cool operation

Temperature management system prevents

overheating to ensure years of enjoyment

Quick access brush port

for easy maintenance

10' Quick-Connect power cord

detaches for easy storage

A.

B.

C.

D.

E.

F.

G.

H.

7